Water-milled colored pavement brick made of recycled aggregate from construction waste and preparation method thereof

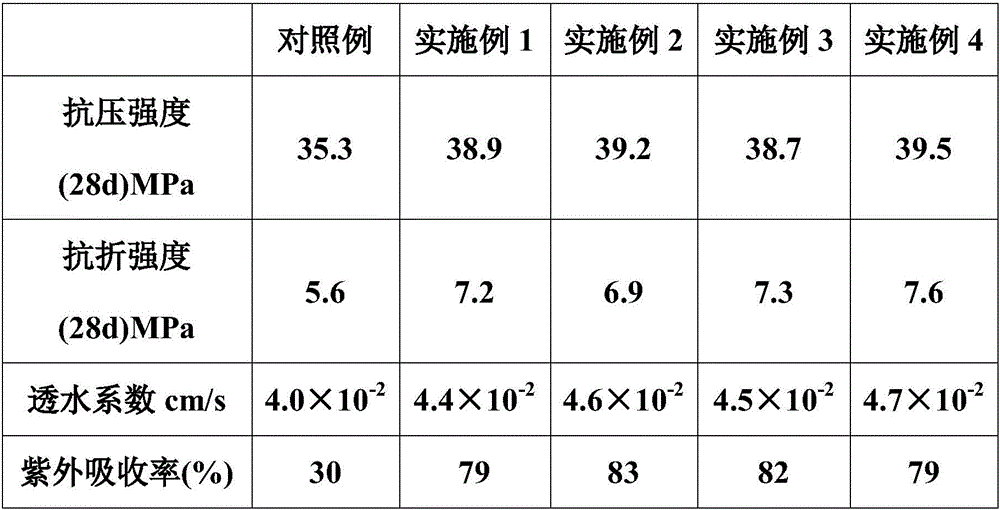

A technology of construction waste and recycled aggregate, applied in the field of building materials, can solve the problems of no anti-ultraviolet radiation, low compressive strength, increased production costs, etc., and achieve good water permeability, long service life, and beautify the environment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] Preparation of water-milled colored pavement bricks from recycled aggregates from construction waste

[0023] Ingredients: fine aggregate 200kg, coarse aggregate 60kg, aggregate improver 5kg, nano-silica 30kg, polyamide 50kg, water reducing agent 0.3kg, cement 100kg, water 40kg.

[0024] The above-mentioned fine aggregate is the construction waste with a particle size of 0-5 mm obtained after the construction waste is crushed, sieved, and removed from the sundries; The construction waste with a diameter of 5-10mm, 10-20mm and 20-30mm is mixed according to the ratio of 2:3:0.6.

[0025] The above-mentioned aggregate modifier is made of attapulgite, sepiolite, diatomite and tourmaline in a ratio of 2:1:0.3:0.5; the particle size of the nano-silica is 30nm.

[0026] The above-mentioned polyamide is polyamide-6; the above-mentioned water-reducer is polycarboxylate high-efficiency water-reducer; the above-mentioned cement is Portland cement.

[0027] The preparation method...

Embodiment 2

[0032] Preparation of water-milled colored pavement bricks from recycled aggregates from construction waste

[0033] Ingredients: fine aggregate 260kg, coarse aggregate 80kg, aggregate improver 10kg, nano-silica 80kg, polyamide 70kg, water reducing agent 0.5kg, cement 140kg, water 70kg.

[0034] The above-mentioned fine aggregate is the construction waste with a particle size of 0-5 mm obtained after the construction waste is crushed, sieved, and removed from the sundries; The construction waste with a diameter of 5-10mm, 10-20mm and 20-30mm is mixed according to the ratio of 2:3:0.6.

[0035] The above-mentioned aggregate modifier is made of attapulgite, sepiolite, diatomite and tourmaline in a ratio of 2:1:0.3:0.5; the particle size of the nano-silica is 50nm.

[0036] The above-mentioned polyamide is polyamide-66; the above-mentioned water-reducer is polycarboxylate high-efficiency water-reducer; the above-mentioned cement is sulphoaluminate cement.

[0037] The preparati...

Embodiment 3

[0042] Preparation of water-milled colored pavement bricks from recycled aggregates from construction waste

[0043] Ingredients: 240kg of fine aggregate, 70kg of coarse aggregate, 8kg of aggregate improver, 80kg of nano-silica, 60kg of polyamide, 0.4kg of water reducing agent, 120kg of cement, and 60kg of water.

[0044] The above-mentioned fine aggregate is the construction waste with a particle size of 0-5 mm obtained after the construction waste is crushed, sieved, and removed from the sundries; The construction waste with a diameter of 5-10mm, 10-20mm and 20-30mm is mixed according to the ratio of 2:3:0.6.

[0045] The above-mentioned aggregate modifier is made of attapulgite, sepiolite, diatomite and tourmaline in a ratio of 2:1:0.3:0.5; the particle size of the nano-silica is 45nm.

[0046] The above-mentioned polyamide is polyamide-610; the above-mentioned water-reducer is polycarboxylate high-efficiency water-reducer; the above-mentioned cement is white cement.

[004...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com