Composite film

A composite film and polyethylene adhesive technology, applied in the field of composite films, can solve the problems of non-waterproof and heat-resistant properties of matte films, limited use range, easy deformation, etc., and achieve excellent chemical resistance stability, good compatibility, The effect of strong water and gas barrier properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] specific implementation plan

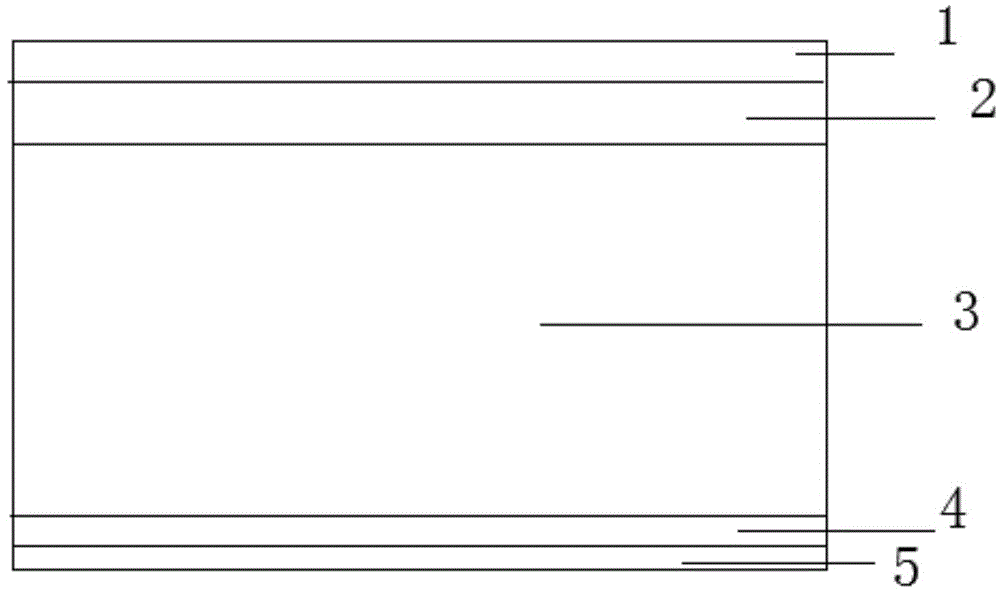

[0014] As shown in the figure, a composite film, the composite film is a three-layer structure, followed by polyethylene resin layer 1, ethylene-vinyl alcohol copolymerization layer 3 and nylon layer 5, polyethylene resin layer and ethylene-vinyl alcohol copolymerization layer 3 are bonded by polyethylene adhesive 2, and the ethylene-vinyl alcohol co-trimeric layer and nylon layer 5 are bonded by adhesive 4.

[0015] Preferably, the ratio of ethylene to vinyl alcohol in the ethylene-vinyl alcohol copolymer layer 3 is 2:3.

[0016] Preferably, the thickness ratio of the polyethylene resin layer 1 , the ethylene-vinyl alcohol copolymer layer 3 and the nylon layer 5 is 1:5:1.

[0017] To sum up, the composite film has excellent heat sealing performance, melting performance, physical and mechanical properties, super water and gas barrier performance and excellent chemical resistance stability, and is compatible with five kinds of solution...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com