Photocatalyst furniture and coating construction process thereof

A construction process and photocatalyst technology, which can be used in coatings, devices for coating liquids on surfaces, and surface pretreatment, etc., can solve problems such as substrate corrosion, and achieve the effect of durable coatings, improved service life, and not easy to peel off.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

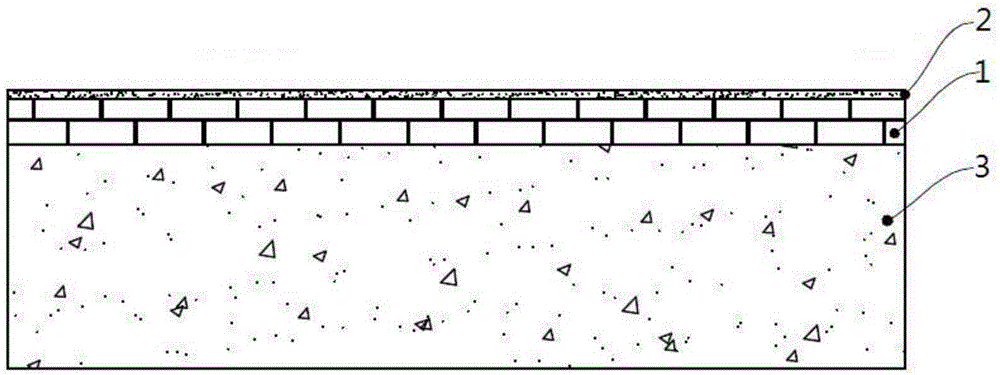

Image

Examples

Embodiment 1

[0052] First configure the primer (non-ionic surfactant solution) with a mass fraction of 0.1% and the anatase nano-titanium dioxide water-soluble sol with a solid content of 0.1%; then follow the coating construction process steps:

[0053] A. The melamine veneer enters the production line, and the sundries and oil stains on the surface are cleaned with detergent;

[0054] B. Adjust the air pressure to 3MPa, use a self-powered spray gun W71 with a diameter of 0.3mm to spray the primer, and the coating thickness is 1μm;

[0055] C. Put the sprayed plate into an oven at 100°C to dry for 1 minute;

[0056] D. Use a self-powered spray gun W71 with a caliber of 1.0mm to spray the photocatalyst with an air pressure of 3MPa, and the coating thickness is 50μm;

[0057] E. Put the board into an oven at 100°C for 3 minutes to dry.

Embodiment 2

[0059] First configure the primer (non-ionic surfactant solution) with a mass fraction of 90% and the anatase nano-titanium dioxide water-soluble sol with a solid content of 3%; then follow the coating construction process steps:

[0060] A. Use a degreasing agent to clean the finished furniture for degreasing and dust removal;

[0061] B. A spray gun with a nozzle diameter of 0.8mm and a 4-horsepower direct-connected portable air compressor are used to spray a layer of primer on the surface of the furniture panel, and the coating thickness is 500μm;

[0062] C. Dry the finished furniture finished with primer for 1 day;

[0063] D. A spray gun with a nozzle diameter of 0.8mm and a 4-horsepower direct-connected portable air compressor are used to spray a layer of titanium dioxide hydrosol consisting of 20 nanometers of anatase titanium dioxide and a solid content of 3% on the surface of the furniture board. The thickness of the coating is 500μm;

[0064] E. Put the sprayed fi...

Embodiment 3

[0066] First configure the primer (anionic surfactant solution) with a mass fraction of 30% and the anatase nano-titanium dioxide water-soluble sol with a solid content of 1%; then follow the coating construction process steps:

[0067] A. Use a neutral detergent to remove oil and dust from the entire furniture panel;

[0068] B. Scrape an appropriate amount of primer on the longitudinal top of the entire furniture board, press it on the primer with a 100μm wire rod, and scrape to the other end at a constant speed of 3cm / s, and the coating thickness is 150μm;

[0069] C. Put the plate into the tunnel oven and pass through three temperature zones of 50°C, 80°C, and 120°C at a speed of 5cm / s;

[0070] D. Add an appropriate amount of photocatalyst sol to the longitudinal top of the whole piece of furniture with the primer dried, press a 1 μm wire rod on the photocatalyst sol, and scrape to the other end at a uniform speed of 3 cm / s. The coating thickness is 150 μm;

[0071] E. P...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com