Alkali slag liquid desulfurizer preparation device and method

A technology for preparing a device and a desulfurizing agent is applied in the field of preparing devices for a liquid desulfurizing agent for alkali residues, which can solve the problems of poor production process stability, high filter cloth damage rate, and low degree of automation control, avoiding mechanical solid-liquid separation and avoiding loading and unloading. and conveying, improving the effect of desulfurization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

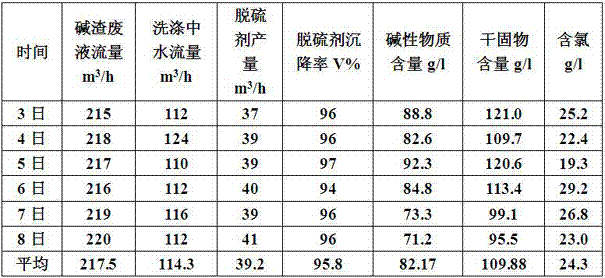

Embodiment 1

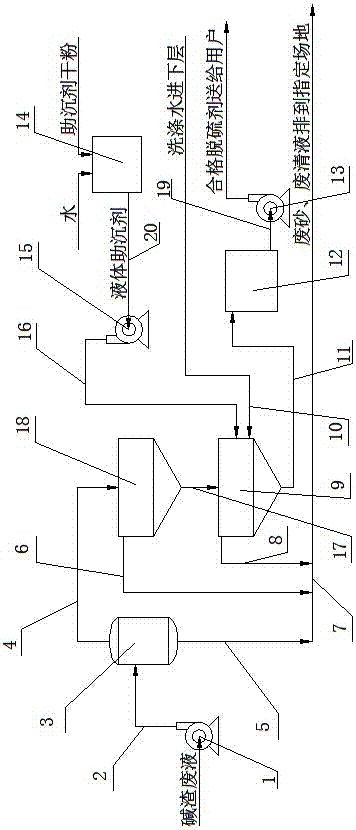

[0029] A preparation device for alkali slag liquid desulfurizer, see attached figure 1 , in the figure: alkali slag delivery pump 1, first pipeline 2, gravity sand chamber 3, second pipeline 4, seventh pipeline 5, first overflow pipeline 6, main collection pipeline 7, second overflow pipeline Flow pipeline 8, chlorine reduction tank 9, third pipeline 10, sixth pipeline 11, finished product buffer tank 12, desulfurization agent delivery pump 13, auxiliary agent tank 14, sedimentation aid pump 15, fourth pipeline 16 , the fifth pipeline 17, the thickener 18, the eighth pipeline 19, the ninth pipeline 20.

[0030] In this embodiment, the alkali slag delivery pump 1 is connected to the desanding device through the first pipeline 2, and the desandering device adopts a gravity sand settler 3, and the solid material in the gravity sand settler 3 is directly settled during the solid-liquid separation process; The top of the gravity sand settler 3 is connected with the thickener 18 th...

Embodiment 2

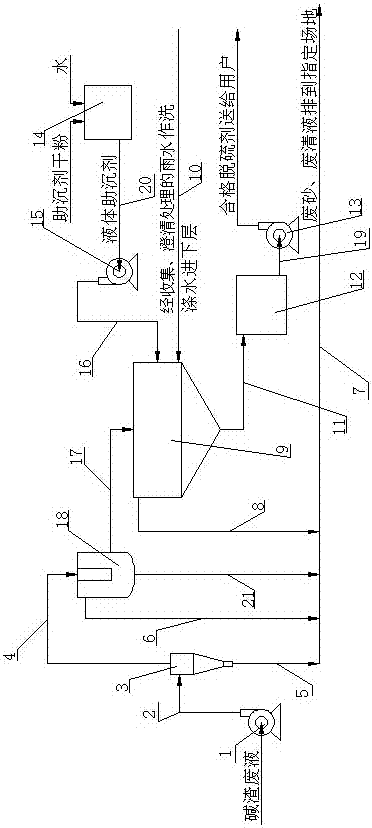

[0041] A preparation device for alkali slag liquid desulfurizer, see attached figure 2 , in the figure: alkali slag delivery pump 1, first pipeline 2, hydrocyclone desander 3, second pipeline 4, seventh pipeline 5, first overflow pipeline 6, total collection pipeline 7, second pipeline Overflow pipeline 8, chlorine reduction tank 9, third pipeline 10, sixth pipeline 11, finished product buffer tank 12, desulfurization agent delivery pump 13, auxiliary agent tank 14, sedimentation aid pump 15, fourth pipeline 16, the fifth pipeline 17, the thick sand settler 18, the eighth pipeline 19, the ninth pipeline 20, and the tenth pipeline 21.

[0042] The difference with Embodiment 1 is: the side wall of the thick sand settler 18 is connected with the top of the chlorine reduction barrel 9 through the fifth pipeline 17, and the bottom end of the thick sand settler 18 is connected with the tenth pipeline 21. Collect the total pipeline 7 connections.

[0043] During the solid-liquid s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com