Drying equipment for ceramic processing and production

A drying equipment and ceramic processing technology, applied in lighting and heating equipment, drying chamber/container, local stirring dryer, etc., can solve the problems of uneven drying of ceramics, increase production loss, increase production cost, etc., and achieve heating effect Good, reduce the work intensity and prolong the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

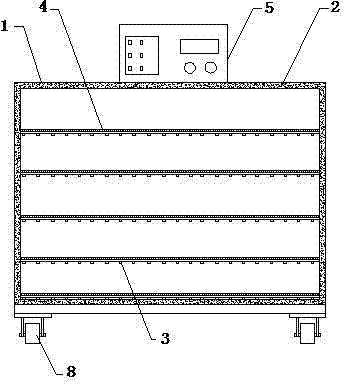

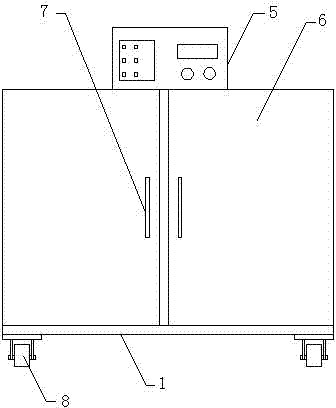

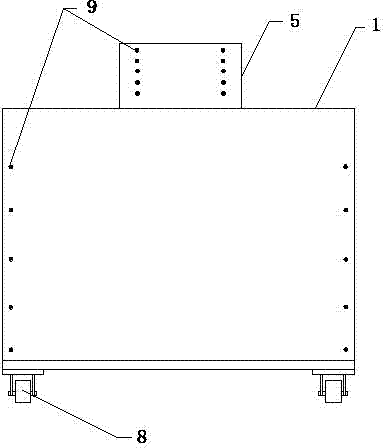

[0021] The technical solutions of the present invention will be further described below with reference to the accompanying drawings.

[0022] Refer to the attached Figure 1-4 The drying equipment for ceramic processing and production as shown includes a container 1, a heat insulating plate is arranged on the outside and on the top cover of the container 1, and rollers 8 are fixedly arranged at the four corners of the bottom of the container 1. The front surface of the container 1 is Two box doors 6 are provided, two rows of wiring holes 9 are opened on the back, and the wiring holes 9 on one side of the electric control system 5 correspond to the wiring holes 9 on the back of the container 1 one-to-one. A handle 7 is also installed on the door 6, which is convenient for pushing and pulling. The two side walls, the top and the bottom of the container 1 are covered with a lining 2, and the lining 2 is a thermal insulation material using ceramic fibers. Inside the container 1 S...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com