Lithium ion battery silicon metal composite negative electrode material and preparation method thereof

A technology for lithium-ion batteries and negative electrode materials, which is applied in the direction of battery electrodes, circuits, electrical components, etc., can solve problems such as capacity fading, and achieve the effects of improving electrical conductivity, stable structure, and good electrochemical stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] Weigh 140g of Si (100nm), 150g of Ni powder (500 mesh), 50g of glucose and 600g of AGP-8, and knead for 3 hours under a twin-screw extruder with a diameter of 30mm to obtain a mixed precursor.

[0033] Take 20g of the above-mentioned mixed precursor and put it into a ceramic crucible, put the covered ceramic crucible into a high-temperature tube furnace; pump a vacuum and pass high-purity argon; keep it at 1000°C for 1.5h, and the theoretical stoichiometric formula is SiNi 0.511 -10.13C composite anode material.

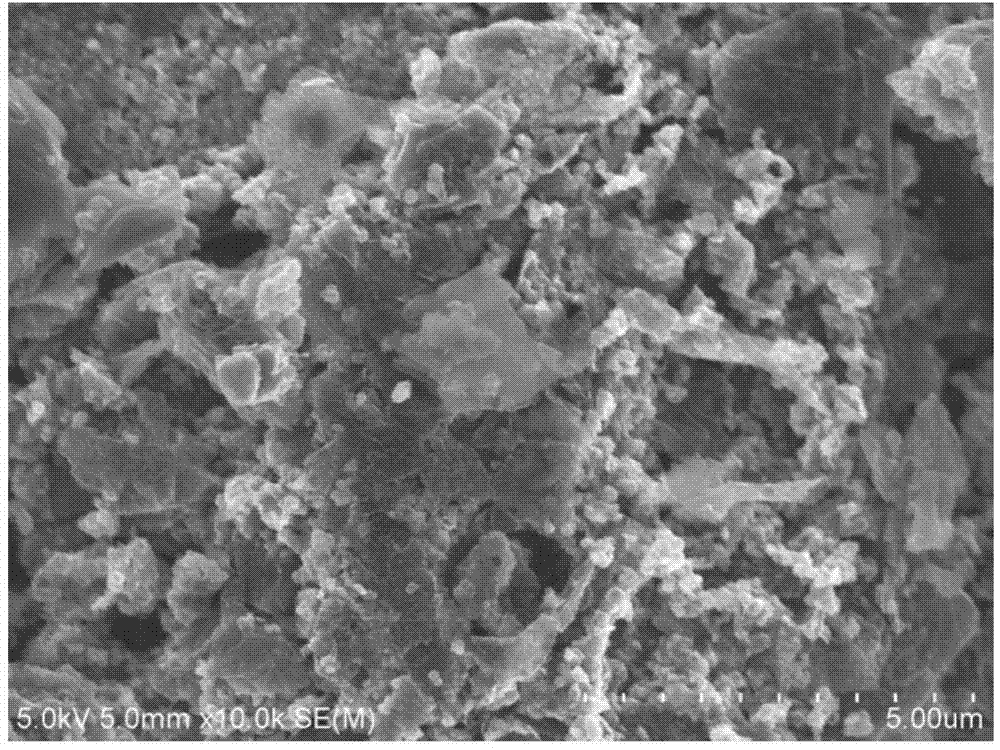

[0034] The above composite negative electrode material was mechanically ground and sieved through a 325-mesh steel sieve to obtain a powdered silicon-metal composite negative electrode material with a D50 particle size of 4.9 μm. figure 1 The SEM image of the silicon-metal composite negative electrode material shows that nano-silicon particles with smaller particle sizes are distributed in the composite material. image 3 The XRD pattern of the silicon-metal ...

Embodiment 2

[0037] Weigh 240g SiO (350 mesh), 150g Ni powder (500 mesh), 50g glucose and 600g AGP-8, and knead them for 4 hours under a twin-screw extruder with a diameter of 30mm to obtain a mixed precursor.

[0038] Take 20g of the above mixture and put it into a ceramic crucible, put the covered ceramic crucible into a high-temperature tube furnace; evacuate and pass argon; keep it at 1050°C for 1.5h, and the theoretical stoichiometric formula is SiNi 0.47 Composite anode material of O-9.28C.

[0039]The above composite negative electrode material was mechanically ground and sieved through a 325-mesh steel sieve to obtain a powdered silicon-metal composite negative electrode material with a D50 particle size of 8.7 μm.

[0040] figure 2 The SEM image of the silicon-metal composite anode material in the figure shows that the composite material obtained by high-temperature calcination has a good particle size distribution. Figure 4 The XRD pattern of the silicon-metal composite anode...

Embodiment 3

[0042] Weigh 240g SiO (350 mesh), 150g SnO 2 Powder (20nm), 50g of glucose and 600g of AGP-8 were kneaded for 3 hours under a twin-screw extruder with a diameter of 30mm to obtain a mixed precursor.

[0043] Take 20g of the above mixture and put it into a ceramic crucible, put the covered ceramic crucible into a high temperature tube furnace; evacuate and pass argon; keep it warm at 1050°C for 1.5h, and the theoretical stoichiometric formula is SiSn 0.18 o 1.37 -9.28C composite anode material.

[0044] The above composite negative electrode material was mechanically ground and sieved through a 325-mesh steel sieve to obtain a powdered silicon-metal composite negative electrode material with a D50 particle size of 12.3 μm.

[0045] The preparation and testing methods of the battery are the same as in Example 1. The initial reversible capacity of the prepared silicon-metal composite anode material is 462.2mAh / g, and the capacity retention rate after 10 cycles is 97.4%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com