Device and method for testing electrochemical repassivation performance of metal material

A material electrochemistry and testing device technology, applied in measurement devices, analytical materials, scientific instruments, etc., can solve problems such as damage to the oxide film on the surface of the substrate, large elastic-plastic deformation changes, large elastic-plastic deformation, etc., to ensure the effectiveness. and assessability, avoiding repassivation, improving accuracy and controllability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention is further described as follows in conjunction with accompanying drawing and embodiment:

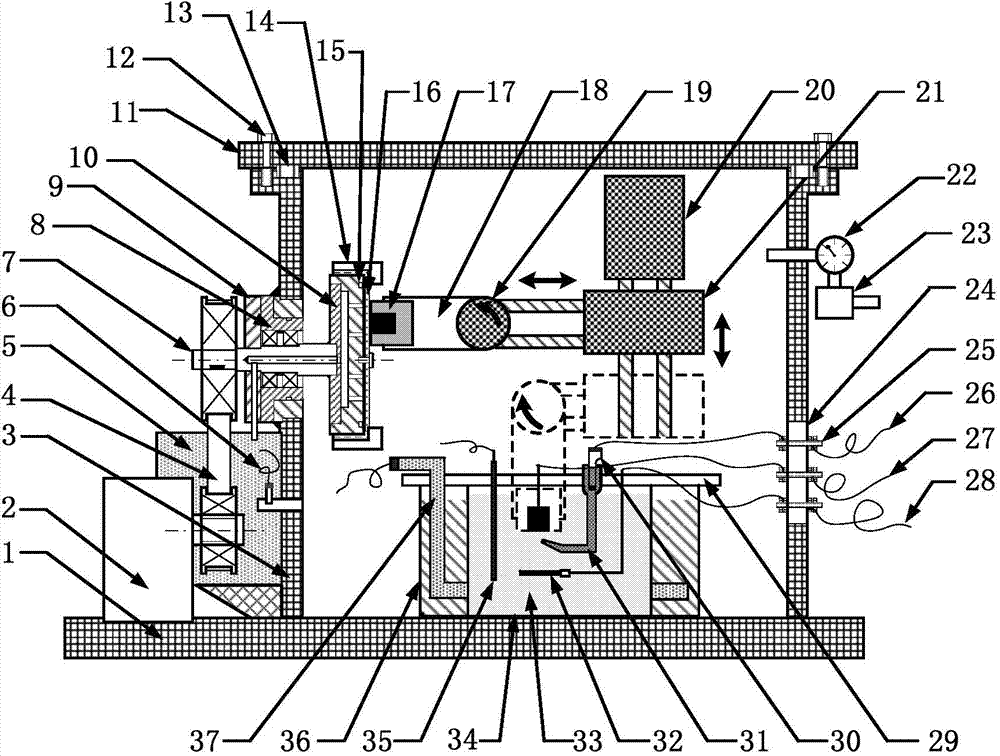

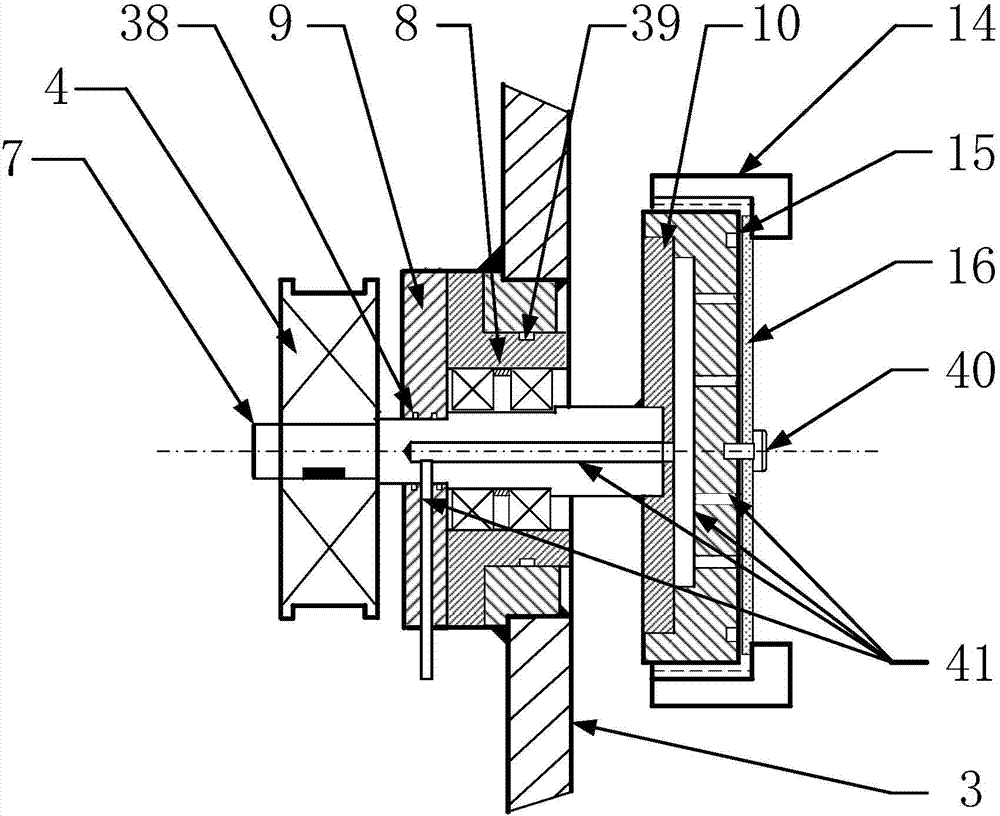

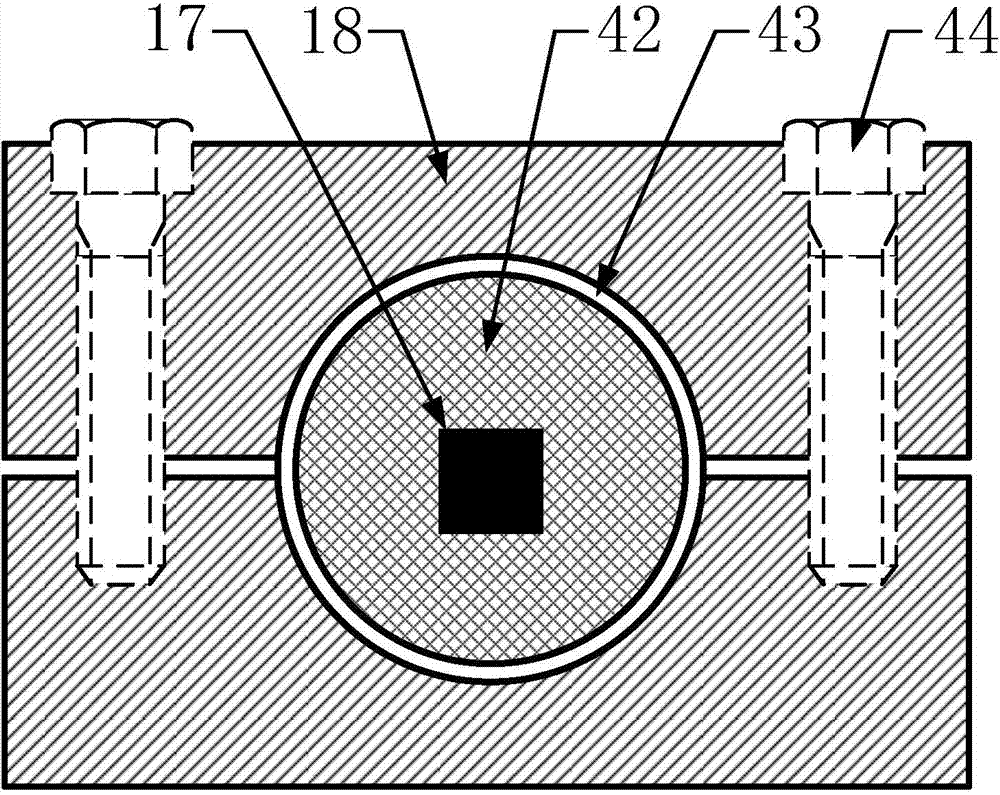

[0028] Such as figure 1 As shown, the repassivation test device of the present invention comprises a closed box 3 and a drive motor 2 fixed on the base 1, and a belt transmission system 4 connects the drive motor 2 and the shaft 7 of the rotary chuck 10, and the shaft is composed of a bearing 8 and an outer shaft The seat 9 is fixed on the left wall of the airtight box 3, and the abrasive material 16 is fixed on the rotary suction cup 10; the vacuum pump 5 is fixed outside the airtight box 3, connected to the air passage of the airtight box 3 and the rotary suction cup 10, and the intake valve 23 is also connected to the airtight box 3. One end of the sample fixture 18 has a sample installation port, and the other end is fixed on the rotary cylinder 19. The rotary cylinder 19 is fixed on the horizontal translation cylinder 21, the horizontal translation cyli...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com