A Casting and Rolling Method for Eliminating Delta Ferrite in Maraging Stainless Steel Strip

A technology of delta ferrite and stainless steel, which is applied in the field of casting and rolling to eliminate delta ferrite in maraging stainless steel strips, can solve problems such as deterioration of performance, reduce surface defects, improve corrosion resistance and service life And safety, the effect of improving strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

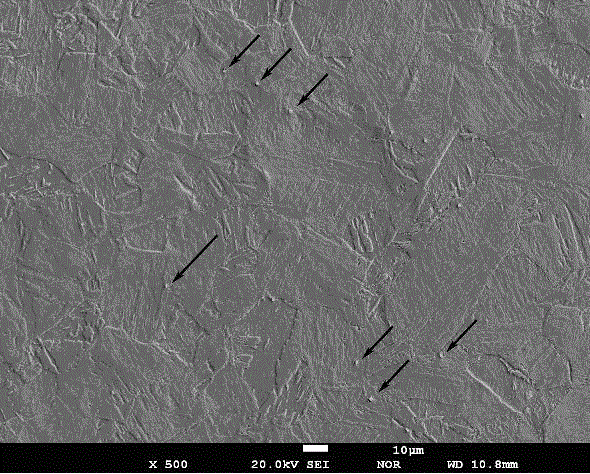

Image

Examples

Embodiment 1

[0029] To prepare a maraging stainless steel strip with a thickness of 1.0mm, the process steps are as follows:

[0030](1) According to the mass percentage: C 0.007, N 0.01, Mn 0.32, Si 0.15, Al 0.33, Cr 12, Ni 9, Mo 4, Cu 2, Ti 1, the balance is Fe and the chemical composition of unavoidable impurities Select raw materials, heat the raw materials to 100°C and keep them warm for 120 minutes, put them into a vacuum induction melting furnace, and smelt them in a vacuum environment with a vacuum degree of 0.1-1Pa to obtain molten steel;

[0031] (2) Under the protection of argon, molten steel is poured into a twin-roll thin strip casting and rolling machine for casting and rolling, wherein the pouring temperature is 1520°C, the casting and rolling speed is 30m / min, and the casting and rolling force is 50kN, and finally a steel sheet with a thickness of 1.0mm is obtained. Thin strip of maraging stainless steel.

[0032] In addition, a thin strip of maraging stainless steel with ...

Embodiment 2

[0035] To prepare a maraging stainless steel strip with a thickness of 1.5mm, the process steps are as follows:

[0036] (1) According to the mass percentage: C 0.01, N 0.01, Mn 0.5, Si 0.3, Al 0.2, Cr 11, Ni 8, Mo 3.5, Cu 1.5, Ti 1.5, the balance is the chemical composition of Fe and unavoidable impurities Select raw materials, heat the raw materials to 150°C and keep them warm for 120 minutes, put them into a vacuum induction melting furnace, and smelt them in a vacuum environment with a vacuum degree of 0.1-1Pa to obtain molten steel;

[0037] (2) Under the protection of argon, molten steel is poured into a twin-roll thin strip casting and rolling machine for casting and rolling, wherein the pouring temperature is 1500°C, the casting and rolling speed is 30m / min, and the casting and rolling force is 50kN, and finally a steel sheet with a thickness of 1.5mm is obtained. Thin strip of maraging stainless steel.

[0038] In addition, a maraging stainless steel thin strip havin...

Embodiment 3

[0041] To prepare a maraging stainless steel thin strip with a thickness of 2.0 mm, the process steps are as follows:

[0042] (1) According to the mass percentage: C 0.01, N 0.01, Mn 0.2, Si 0.5, Al 0.4, Cr 13, Ni 10, Mo 4, Cu 1.5, Ti 0.5, the balance is the chemical composition of Fe and unavoidable impurities Select raw materials, heat the raw materials to 100°C and keep them warm for 120 minutes, put them into a vacuum induction melting furnace, and smelt them in a vacuum environment with a vacuum degree of 0.1-1Pa to obtain molten steel;

[0043] (2) Under the protection of argon, molten steel is poured into a twin-roll thin strip casting and rolling machine for casting and rolling, wherein the pouring temperature is 1480°C, the casting and rolling speed is 30m / min, and the casting and rolling force is 50kN, and finally a steel sheet with a thickness of 2.0mm is obtained. Thin strip of maraging stainless steel.

[0044] In addition, a maraging stainless steel thin strip ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com