Preparation methods of anti-aging wood-plastic composite and light stabilizer

A technology of wood-plastic composite materials and light stabilizers, which is applied in textiles and papermaking, fiber treatment, plant fibers, etc., can solve the problems of complex aging mechanism of wood-plastic composite materials, low molecular weight of light stabilizers, and easy decomposition, etc. Anti-ultraviolet aging performance, good physical and mechanical properties and processability, and the effect of improving processability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0056] This embodiment adopts existing ultraviolet absorber UV-P as light stabilizer, calcium-zinc composite stabilizer as thermal stabilizer, stearic acid as lubricant, dioctyl phthalate as plasticizer, used for Prepare wood-plastic composite material, the raw material component that it comprises is:

[0057] PVC: 100 parts,

[0058] Modified sisal fiber: 40 parts,

[0059] Heat stabilizer: 2.5 parts,

[0060] Lubricant: 1 part,

[0061] Antioxidant: 0.5 parts,

[0062] Plasticizer: 10 parts,

[0063] Light stabilizer: 2 parts;

[0064] Its preparation methods include:

[0065] Step 1. Put the above-mentioned raw material components into a high-speed mixer together, and mix at high speed for 60s to obtain pre-mixed raw materials;

[0066] Step 2. Use an open plastic mixer to plasticize the mixed premixed raw materials. The temperature of the front roller is 175°C, the temperature of the rear roller is 180°C, and the mixing time is 5min-10min;

[0067] Step 3. Place th...

Embodiment 2

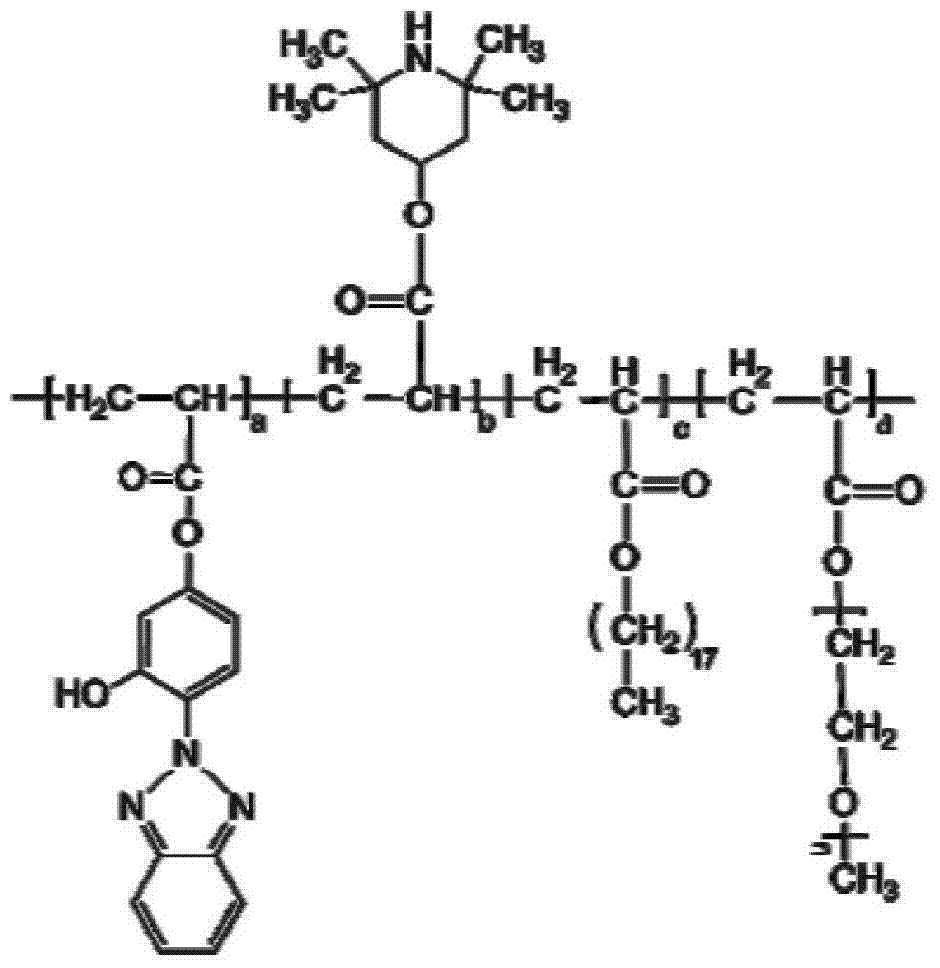

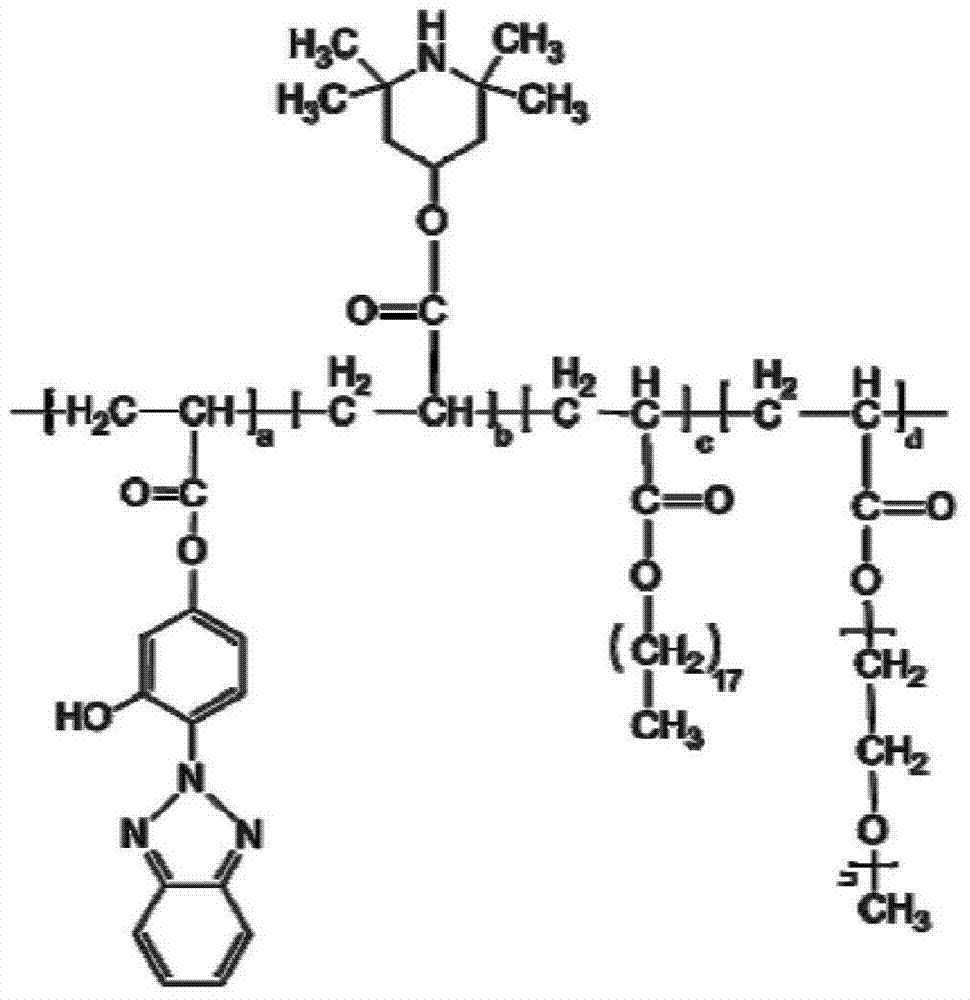

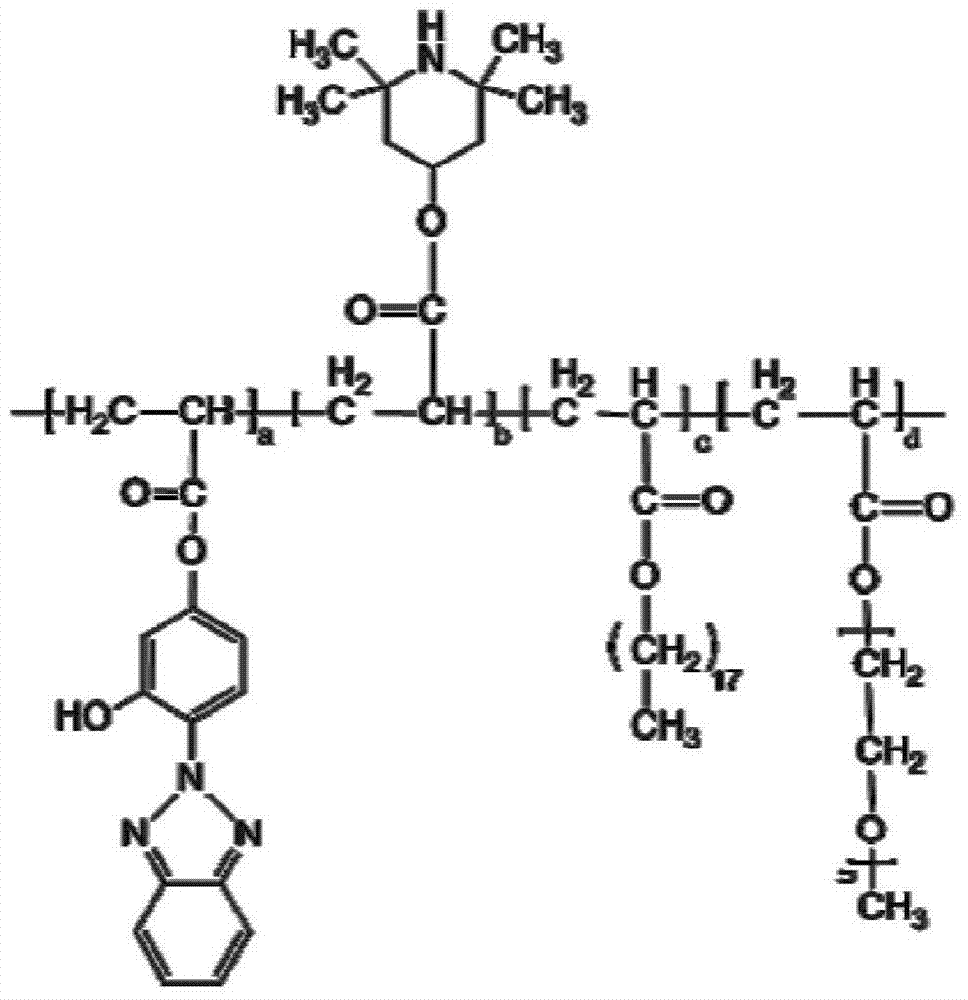

[0069] In this embodiment, a comb-shaped composite benzotriazole polymer is used as a light stabilizer, a calcium-zinc composite stabilizer is used as a heat stabilizer, stearic acid is used as a lubricant, and dioctyl phthalate is used as a plasticizer. agent, used to prepare wood-plastic composite materials, the raw material components included are:

[0070] PVC: 100 parts,

[0072] Heat stabilizer: 2.5 parts,

[0073] Lubricant: 1 part,

[0074] Antioxidant: 0.5 part,

[0075] Plasticizer: 10 parts,

[0076] Light stabilizer: 3 parts;

[0077] Its preparation methods include:

[0078] Step 1. Put the above-mentioned raw material components into a high-speed mixer together, and mix at high speed for 60s to obtain pre-mixed raw materials;

[0079] Step 2. Use an open plastic mixer to plasticize the mixed premixed raw materials. The temperature of the front roller is 175°C, the temperature of the rear roller is 180°C, and the mixing time ...

Embodiment 3

[0082] In this example, a wood-plastic composite material is prepared by using a comb-shaped composite benzotriazole polymer as a light stabilizer, and the raw material components included are:

[0083] PVC: 100 parts,

[0084] Modified sisal fiber: 40 parts,

[0085] Heat stabilizer: 2.5 parts,

[0086] Lubricant: 1 part,

[0087] Antioxidant: 0.5 part,

[0088] Plasticizer: 10 parts,

[0089] Light stabilizer: 3 parts;

[0090] Its preparation methods include:

[0091] Step 1. Put the above-mentioned raw material components into a high-speed mixer together, and mix at high speed for 60s to obtain pre-mixed raw materials;

[0092] Step 2. Use an open plastic mixer to plasticize the mixed premixed raw materials. The temperature of the front roller is 175°C, the temperature of the rear roller is 180°C, and the mixing time is 5min-10min;

[0093] Step 3. Place the compound obtained in step 2 into a plate vulcanizer and mold it into a plate with a thickness of 4mm. The mol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com