a raise y 2 nimno 6 Methods for the Properties of Ceramic Multiferroics

A technology of performance and ceramics, applied in the field of improving the multiferroic properties of Y2NiMnO6 ceramics, to achieve the effects of improved multiferroic properties, large polarization value and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] (1) Preparation of powder: with analytically pure grade yttrium nitrate (Y(NO 3 ) 3 ·6H 2 O), nickel nitrate (Ni(NO 3 ) 3 ·6H 2 O) and manganese acetate (C 4 h 6 MnO 4 ·6H 2 O) etc. as the main raw material, press Y 2 NiMnO 6 (and Ni self-excess 3%) Weigh the raw materials that meet the stoichiometric ratio. Then weigh oxalic acid according to the total number of metal ions in molar ratio: oxalic acid=1:2, add appropriate amount of distilled water, heat and stir at 80°C until completely dissolved, heat and stir at 150°C to obtain black dry gel, and finally calcined at 1000°C for 15 hours to obtain Ni from excess Y 2 NiMnO 6 Powder.

[0020] (2) Forming: pass the obtained product in (1) through a 120-mesh sieve, add a binder with a polyvinyl alcohol content of 5%, manually granulate, and dry-press under a pressure of 10-100 MPa to form a disc-shaped green body.

[0021] (3) Sintering: put the green body obtained in (2) into the crucible, add padding and sin...

Embodiment 2

[0025] All the other are the same as embodiment 1, and the self-excess of Ni is 5% in the step (1).

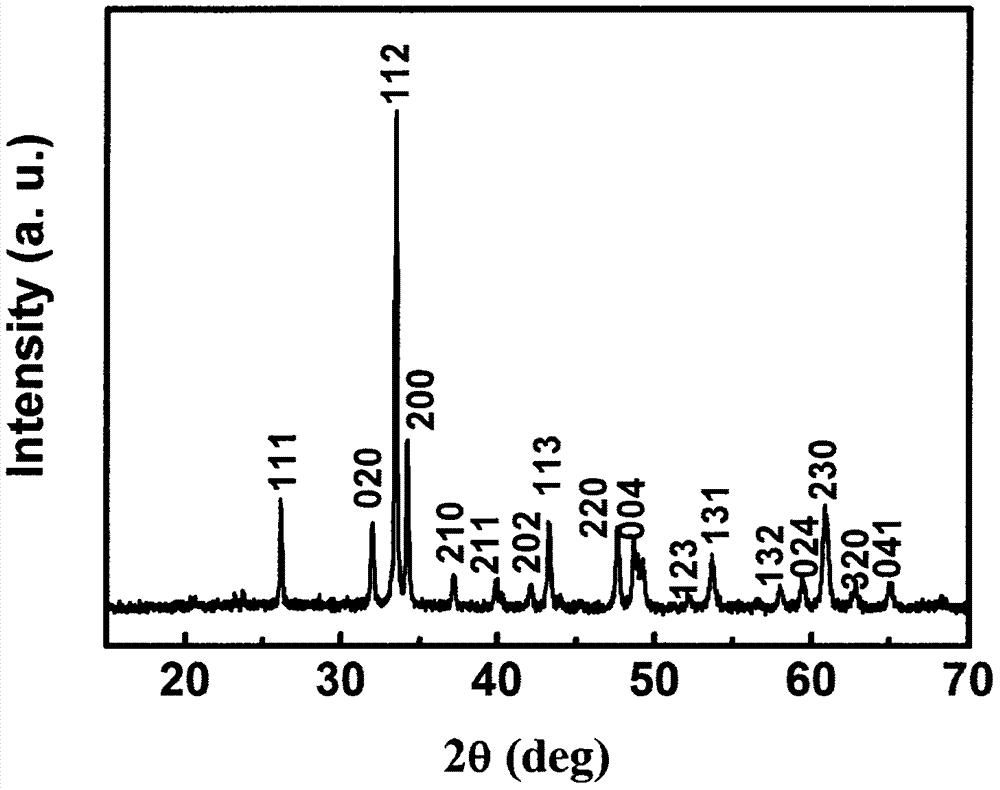

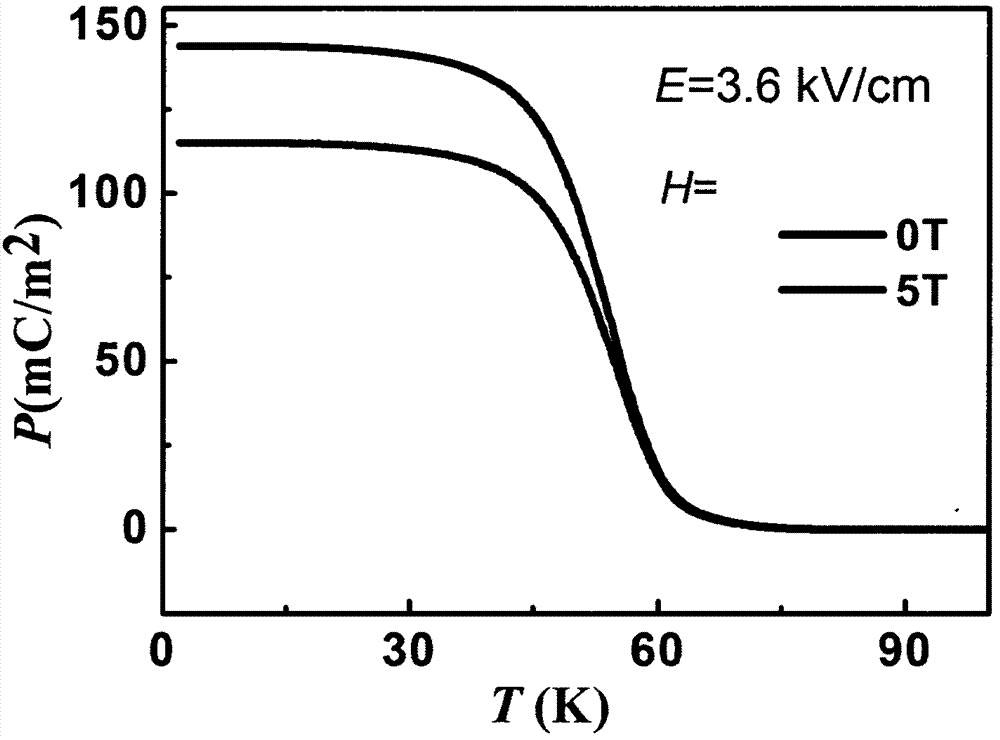

[0026] The X-ray diffraction pattern of the powder obtained by grinding the prepared ceramics of step (3) is as follows image 3 It can be seen that the prepared Y 2 NiMnO 6 is a pure phase; Y 2 NiMnO 6 The variation of the polarization value of ceramics with temperature under different magnetic fields is as follows: image 3 As shown, it can be seen that when there is no magnetic field, its polarization value is 154mC / m 2 , its polarization value becomes 117mC / m under the magnetic field of 5T 2 , its magnetoelectric coupling coefficient ME (magnetoelectric coupling coefficient ME={[P(0)-P(H)] / P(0)}*100%) reaches 24%.

Embodiment 3

[0028] All the other are the same as embodiment 1, and the self-excess of Ni is 7% in the step (1).

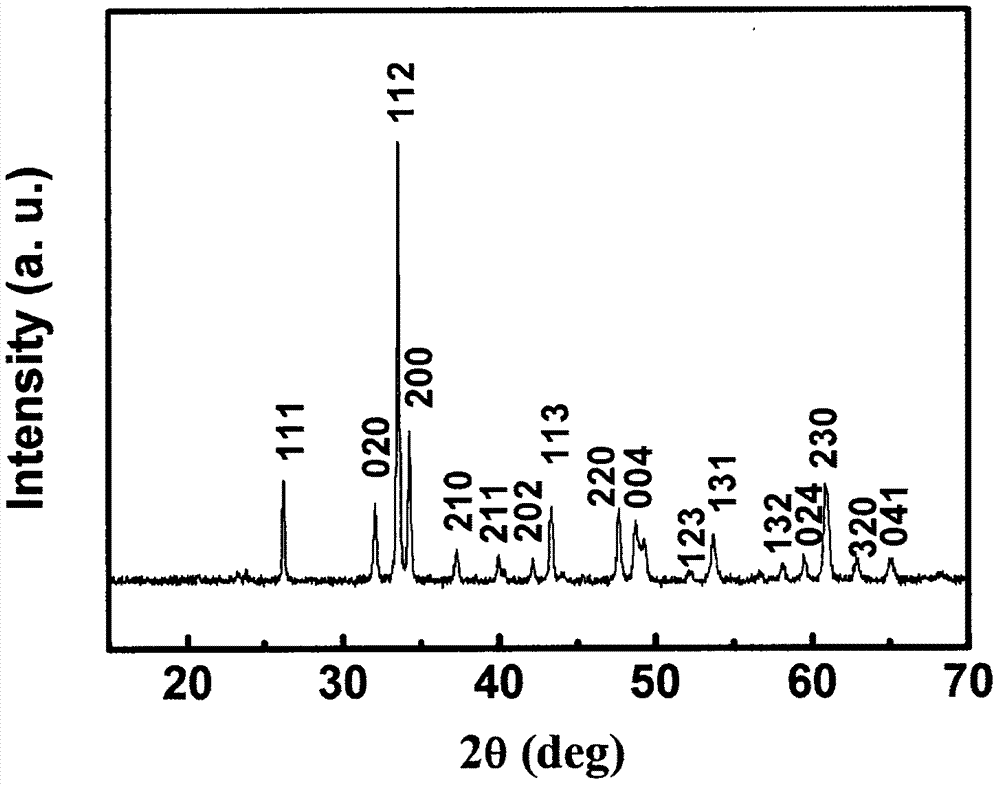

[0029] The X-ray diffraction pattern of the powder obtained by grinding the prepared ceramics of step (3) is as follows Figure 5 It can be seen that the prepared Y 2 NiMnO 6 is a pure phase; Y 2 NiMnO 6 The variation of the polarization value of ceramics with temperature under different magnetic fields is as follows: Image 6 As shown, it can be seen that in the absence of a magnetic field, its polarization value is 165mC / m 2 , its polarization value becomes 121mC / m under the magnetic field of 5T 2 , its magnetoelectric coupling coefficient ME (magnetoelectric coupling coefficient ME={[P(0)-P(H)] / P(0)}*100%) reaches 27%.

[0030] For multiferroic materials, it has been expected that its polarization value is large and the magnetoelectric coupling is strong. from Figure 7 It can be seen that by changing the percentage of Ni self-excess, not only can Y 2 NiMnO 6 The ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com