A kind of processing method of quartz glass wafer blank

A technology for quartz glass wafers and processing methods, which is applied in glass molding, glass production, glass manufacturing equipment, etc., can solve the problems of inability to prepare quartz glass wafer blanks, inability to realize continuous operation, unfavorable industrial scale-up, etc., and achieve It is conducive to industrialization, saving raw materials, and high production efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

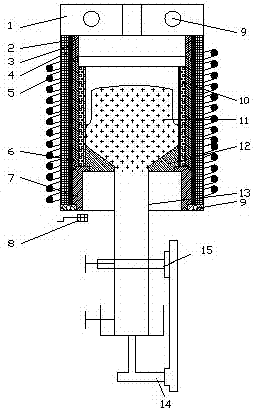

[0025] In order to better understand the method for processing a quartz glass wafer blank according to the present invention, the present invention will be further described below in conjunction with the accompanying drawings.

[0026] A processing method for a quartz glass wafer blank, comprising the following steps:

[0027] A. Use an intermediate frequency heating furnace to heat the quartz glass ingot to a molten state;

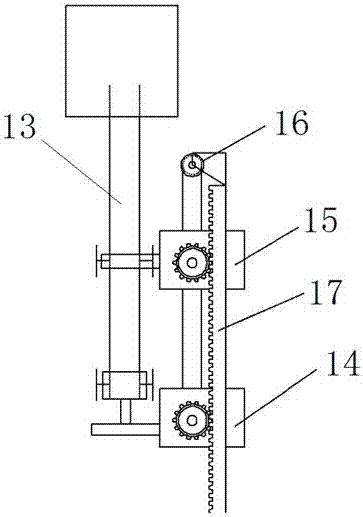

[0028] B. First combine the first traction system with the quartz glass weight, and then move downwards; before the first traction system draws to the bottom of the equipment, adjust the travel speed of the second traction system and the travel speed of the first traction system Consistent, the second traction system is combined with the quartz glass wafer blank; then, the first traction system and the second traction system advance simultaneously and draw downward;

[0029] C. After the first traction system draws the wafer blank to the required length,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com