Device and method for producing continuous graystone fiber

A technology of basalt fiber and basalt, applied in the field of devices for producing continuous basalt fiber, can solve the problems of low product quality, shallow electric melting pool, existence of dead ends, etc., so as to improve quality and output, increase furnace volume, and reduce waste products rate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

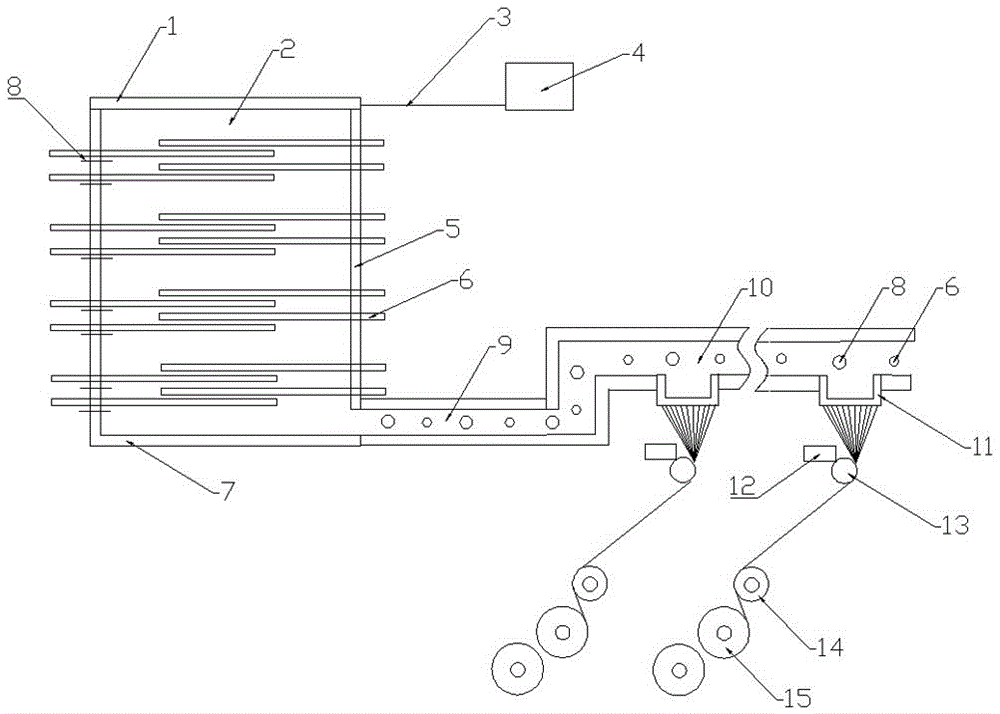

[0030] The technical solution of the present invention will be described in detail below in conjunction with the accompanying drawings.

[0031] as attached figure 1 As shown, a device and method for producing continuous basalt fiber of the present invention, the device and method include a kiln cover 1, a kiln 2, a feeding device 4, a liquid flow hole 9, a feeding channel 10, and a wire drawing device , the electrode assembly and the temperature control device, the bottom of the kiln cover 1 and the feeding device 4 are fixedly connected through the connecting rod 3, the feeding device 4 is provided with a plurality of feeding holes, and the kiln cover 1 and the feeding device 4 are located at the top of the kiln 2; A flow hole 9 is arranged between the kiln 2 and the supply channel 10, and the flow hole 9 communicates with the kiln 2 and the supply channel 10; a plurality of drawing devices are arranged on the side of the supply channel 10, and the bottom of each drawing dev...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com