Production process for drawing copper pipe

A production process, copper tube technology, applied in wire drawing dies, mandrels, etc., can solve problems such as low production efficiency, and achieve the effects of improving quality, reducing friction, and reducing resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

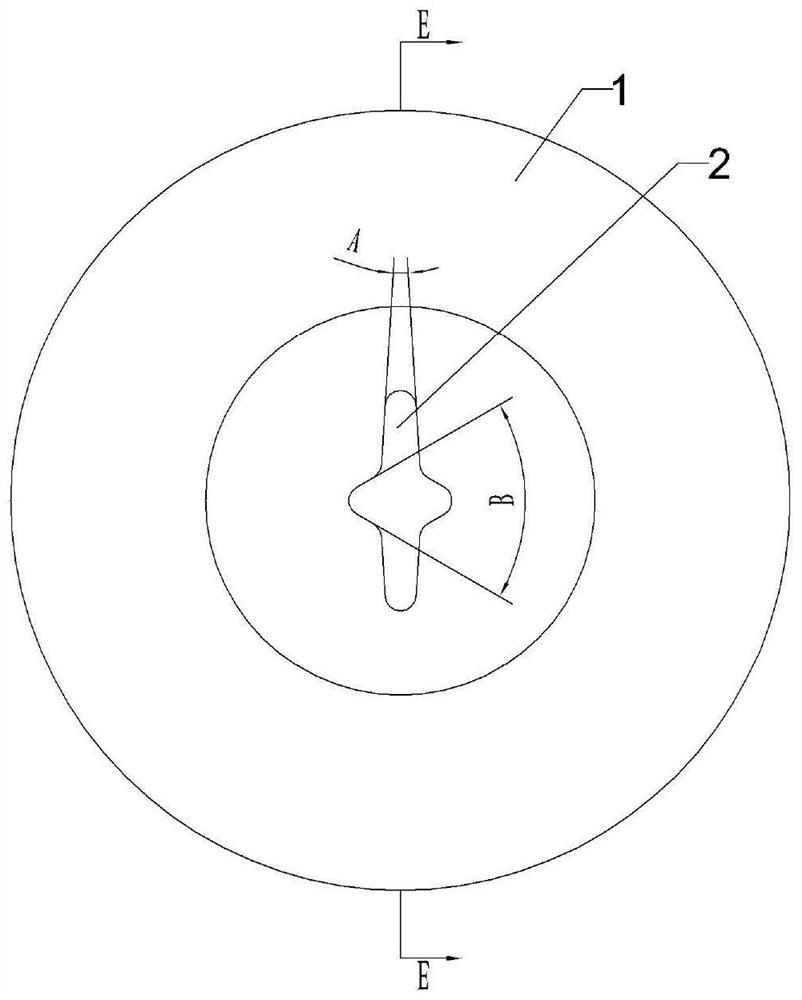

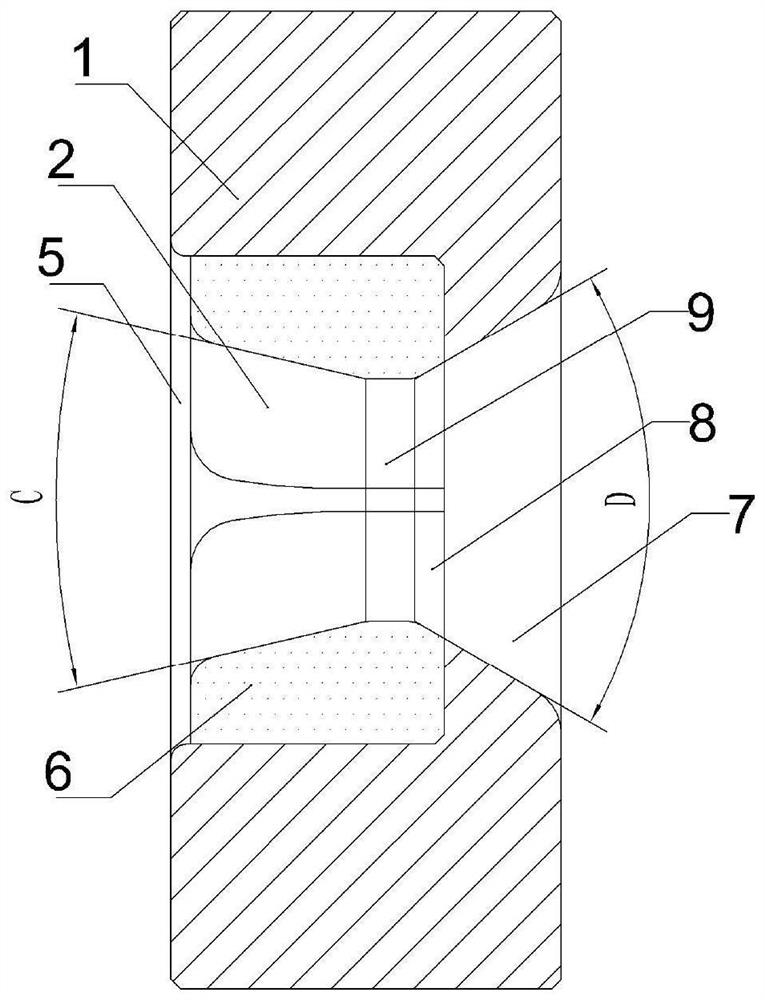

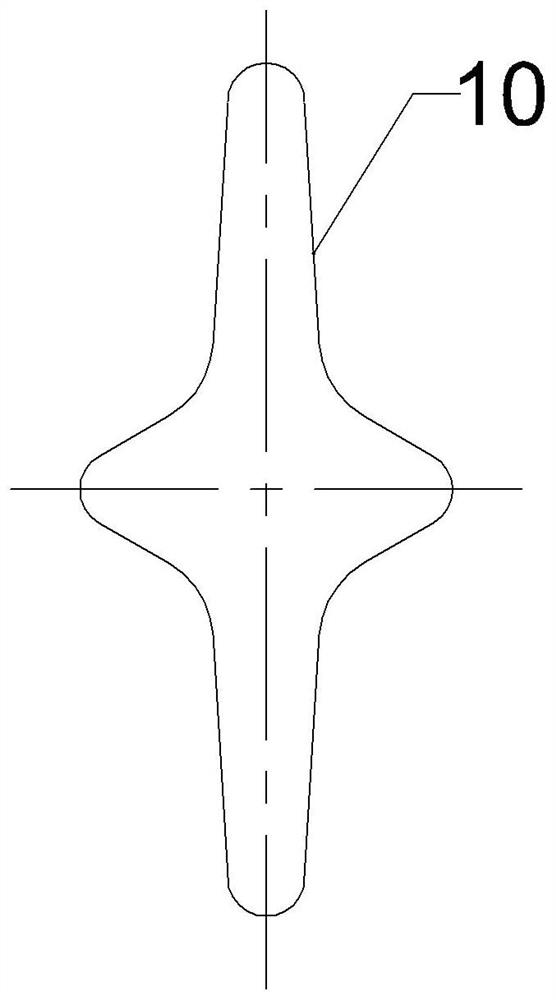

[0045] A production process for drawing copper pipes, which uses a drawing die as shown in the figure for drawing, and the drawing die includes an outer die and a moving core 10 . Such as figure 1 and figure 2 As shown, the outer mold includes a mold casing 1 and a mold core 6, the mold casing 1 has a through hole in the axial direction, and the mold core 6 is embedded in the through hole. A tapered core hole 2 is opened axially on the mold core 6 , and the right end of the core hole 2 is connected with a shaping hole 9 and a connecting hole 8 in sequence. Taper of core hole 2 ( figure 2 The C angle) is 15-70°, specifically, the taper of the core hole 2 in this embodiment is 26°. The cross-section of the core hole 2 is cross-shaped, and the length of the cross-shaped horizontal part is shorter than the length of the vertical part. Specifically, the length of the vertical part at the small diameter end of the core hole 2 is 27-29mm, which is 28mm in this embodiment. The co...

Embodiment 2

[0060] The difference between this embodiment and the first embodiment lies in that the structure of the oiling mechanism is different. Specifically, such as Figure 6 As shown, the oiling mechanism includes a sleeve 15, and the sleeve 15 is axially penetrated with a channel 14 for the copper pipe to pass through. The right end of the sleeve 15 can be installed on the left end of the outer mold by bolts. After installation, the channel 14 is connected to the outer mold. Via connected.

[0061] On the channel 14 inwalls, an oiling sleeve 22 is installed in rotation, combined with Figure 7 It can be seen that the oil-coated sleeve 22 includes a mesh-like skeleton 23, and the skeleton 23 is filled with an oil-absorbing layer 24. In this embodiment, the oil-absorbing layer 24 adopts oil-absorbing cotton, and the inner wall of the oil-coated sleeve 22 is glued and fixed with an oil-coated layer 25. The oil-coated layer 25 adopts soft and oil-absorbing materials such as sponge an...

Embodiment 3

[0068] Such as Figure 8 As shown, the difference between the present embodiment and the second embodiment is that there is an annular piston chamber 28 inside the sleeve 15, the piston chamber 28 is located on the left side of the oil storage chamber 16, and the piston chamber 28 and the sleeve 15 are arranged concentrically. An annular piston 27 is slidably installed in the piston chamber 28, and the piston 27 is connected with a cylinder. The left end of the piston cavity 28 is uniformly connected with several blowing pipes 26 , and the blowing pipes 26 are obliquely aligned with the entrance of the channel 14 . The right end of the piston chamber 28 is uniformly connected with some air suction pipes 30, the air suction pipe 30 is installed on the inside of the piston chamber 28, the free end of the air suction pipe 30 faces the passage 14, and the air suction pipe 30 is equipped with a unidirectional air inlet towards the piston chamber 28. one-way valve. The outside of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Taper | aaaaa | aaaaa |

| Taper | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com