Bag moving machine with full-automatic bag breaking and discharging functions

A fully automatic, bag breaking technology, applied in the field of bag breaking and unloading of powdery materials, can solve the problems of large volume, large dust production, low efficiency, etc., achieve small volume, reduce production, and reduce labor intensity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

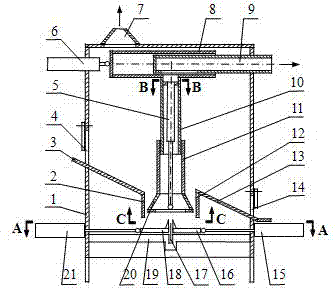

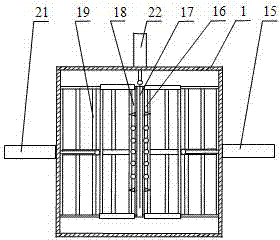

[0035] A fully automatic bag breaking, unloading, and bag moving machine. Such as figure 1 As shown, the fully automatic bag breaking and unloading bag moving machine includes a dustproof airtight cover 1, a left vertical baffle 2, a material bag slide 3, a horizontal sleeve 8, a horizontal air duct 9, a longitudinal inner tube 10, a longitudinal outer Pipe 11, right vertical baffle plate 12, empty bag output slide plate 13, right bag breaking cutter 16, bag cutting cutter 17, left bag breaking cutter 18, bag breaking cutter frame 19 and inner suction hood 20.

[0036] Such as figure 1 As shown, the center of the lower part of the dustproof airtight cover 1 is symmetrically provided with a left vertical baffle 2 and a right vertical baffle 12 . Dust-proof airtight cover 1 left side is provided with material bag slide plate 3, and the upper end of material bag slide plate 3 stretches out into pocket 4, and the lower end of material bag slide plate 3 is fixedly connected w...

Embodiment 2

[0049] A fully automatic bag breaking, unloading, and bag moving machine. Except following technical parameter, all the other are with embodiment 1:

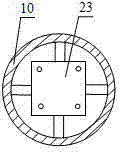

[0050] The side length of the square base 23 is 50-70% of the inner diameter of the longitudinal inner tube 10;

[0051] The width of the bar-shaped sieve holes is 20-30 mm, and the sum of the hole areas of the bar-shaped sieve holes is 60-80% of the area of the sieve plate 33;

[0052] The quantity of steel nails 29 is 6~9;

[0053] The length of blade is 80~85% of the cutter groove 32 lengths of bag breaking cutter frame 19.

[0054] Compared with the prior art, this specific embodiment has the following positive effects:

[0055] 1) The closed end of the transverse air duct 9 of this specific embodiment is movably inserted into the transverse sleeve 8, the longitudinal inner tube 10 is movably inserted into the longitudinal outer tube 11 from the lower end, and the working end of the piston rod of the lateral movement ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com