Removable denture laser processing device and processing method thereof

A technology of laser processing and removable dentures, applied in the field of dentistry, can solve the problems of uncertain processing accuracy, high cost, low impact strength, etc., and achieve the effect of smooth cutting surface without burrs, fast speed and small deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] The present invention will be described in further detail below through specific embodiments and in conjunction with the accompanying drawings.

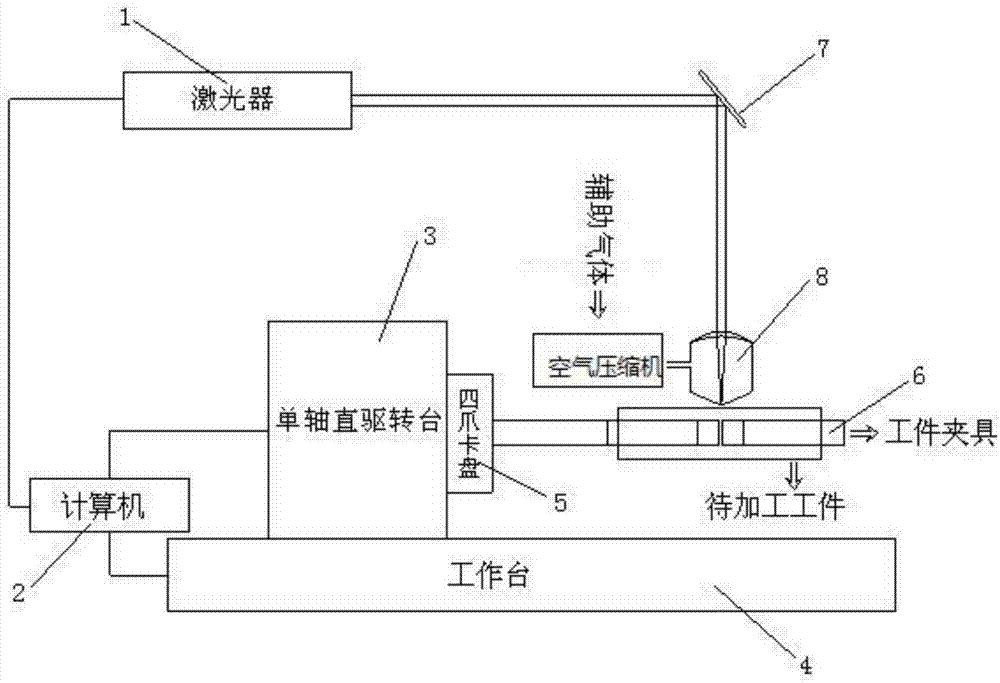

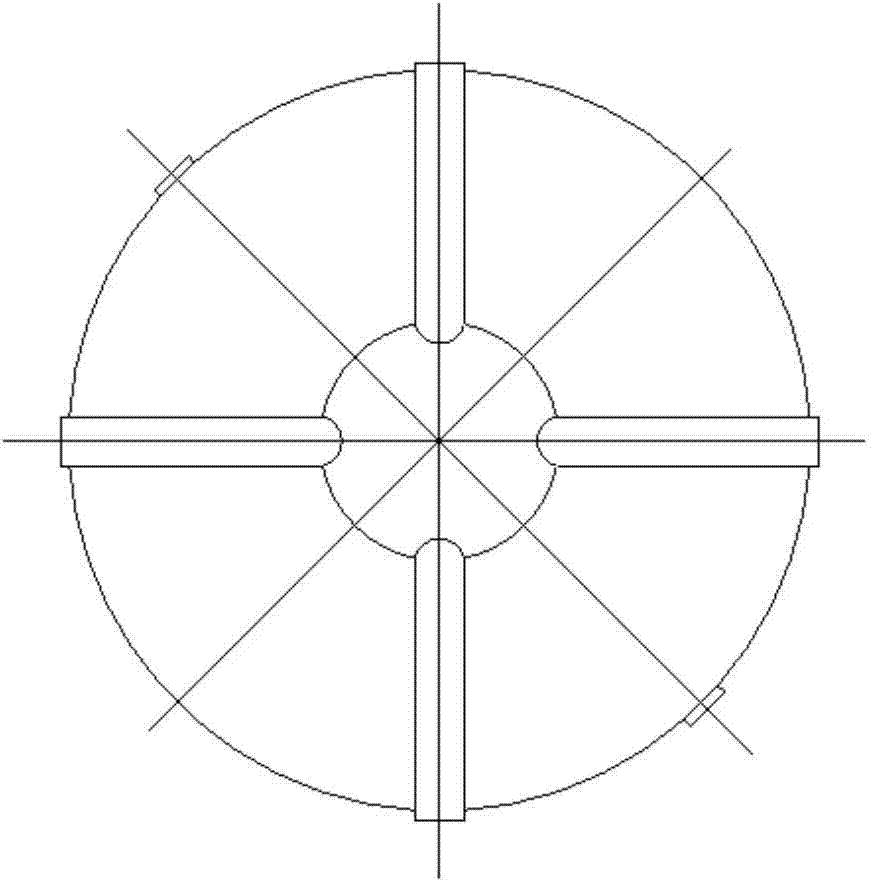

[0041] Such as Figure 1-4 As shown, a laser processing device for a removable denture described in the embodiment of the present invention includes a laser device, a workpiece clamping and moving device, and a computer 2; the laser device is composed of a laser 1, a mirror 7 and a focusing lens 8, and the laser 1 The emitted light is reflected by the 45° total reflection mirror 7 and then focused by the focusing lens 8; the clamping and moving device is composed of a single-axis direct drive turntable 3, a worktable 4, a four-grip chuck 5 and a workpiece fixture 6, and the four-jaw chuck 5 is connected with the single-axis direct-drive turntable 3, the single-axis direct-drive turntable 3 is fixed on the worktable 4, and the workpiece fixture 6 is fixed on the four-jaw chuck 5; the computer 2 and the laser 1, the single-axis ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com