Pixel mapping, alignment and imaging for circular and square based microlens arrays for full volume 3D and multidirectional motion

A lens and array technology, applied in the field of three-dimensional images, can solve problems such as difficult control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

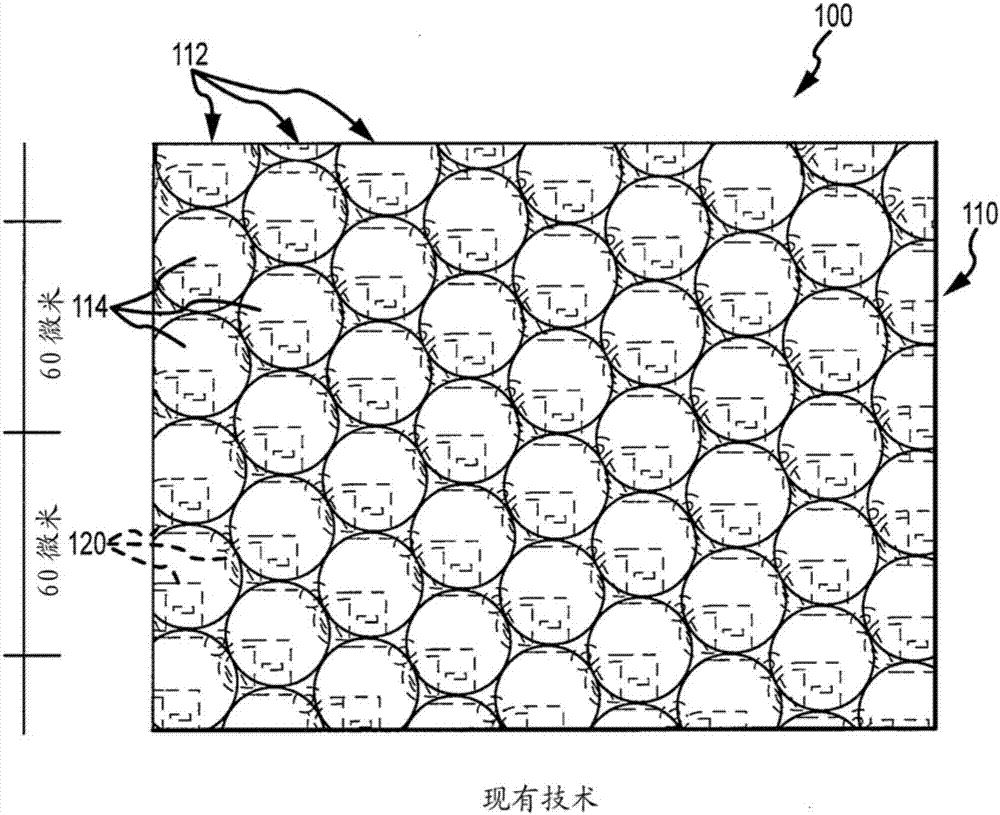

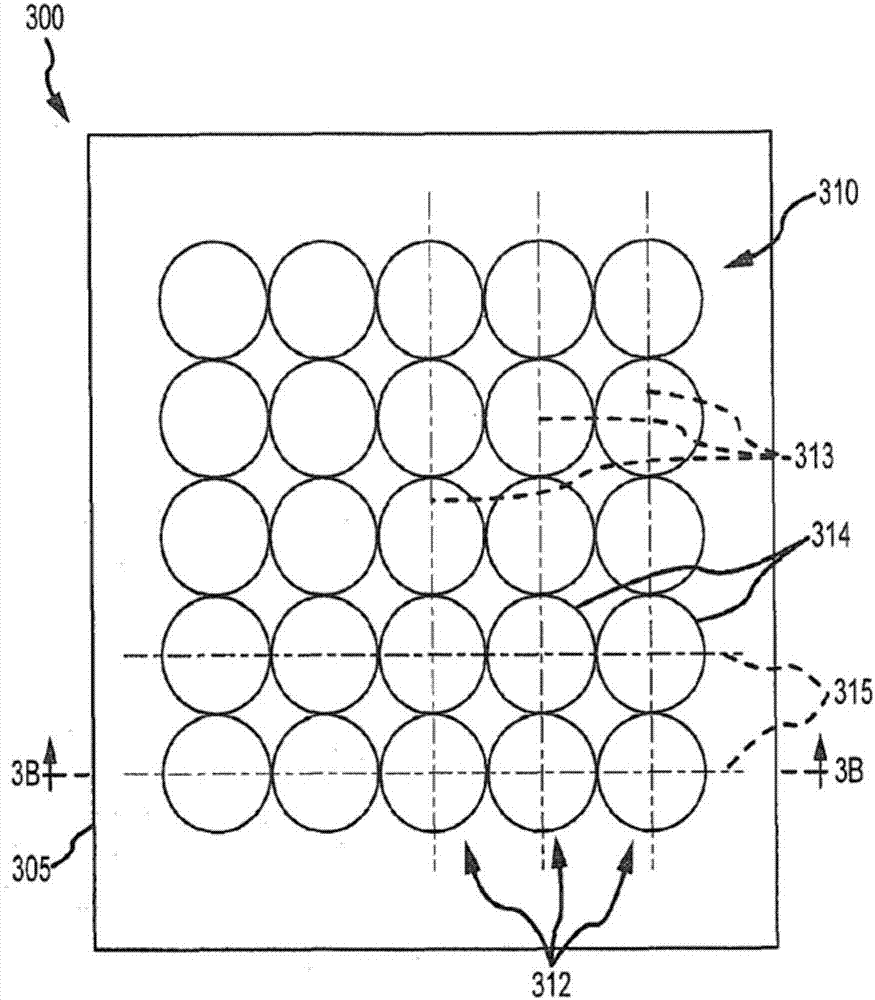

[0039] Briefly, the description is directed to the design of an assembly for combination with a lens array of a printed image provided in an ink layer. A component may be used as, for example but not limited to, a security element or device. lens array with figure 1 with 2 The lens array shown in is partially different in that the lenses are arranged in columns that are not vertically offset, such that the lenses are provided in parallel columns and parallel rows (e.g., adjacent lenses in side-by-side columns have collinear central axis alignment). The lens can be circle or square based, and the underlying image has its pixels mapped and arranged such that the microlens array produces a 3D display image with full volume and, in some cases, multi-directional motion or animation.

[0040] exist Figure 3A with 3B In the embodiment shown in the article 300 (such as a banknote or a label for a product, etc.) has Anti-counterfeiting components or devices. As shown, article 3...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com