Long sharp-point carbonized drill

A sharp-nosed and drill-bit technology, which is applied in the field of long-nosed carbonized drill bits, can solve the problems of reducing the working efficiency of the drill bit, affecting the drilling work of the drill bit, and unsmooth cutting, and achieves a stable structure, smooth chip removal, and smooth cutting. fast effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

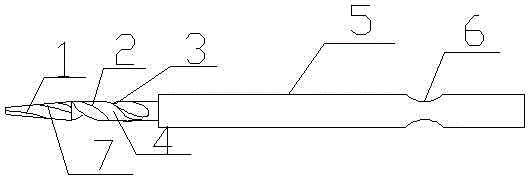

[0017] Reference numerals: 1. Front cutter, 2. S-shaped auxiliary cutter, 3. Drill body, 4. Cutting groove, 5. Drill shank, 6. Positioning groove, 7. Drill point

[0018] In order to make the purpose, technical solution and advantages of the present invention clearer, the following will further describe the implementation of the present invention in detail in conjunction with the accompanying drawings.

[0019] The structure of the long pointed nose carbonized drill bit of the present invention is as figure 1 As shown, a long-tip carbonized drill bit is formed by connecting two parts of a drill shank 5 and a drill body, and is characterized in that: the structure of the drill body is formed by integrally forming two parts of the drill tip 7 and the drill body 3; the drill body 3 It consists of the front end of the ∞-shaped drill body with straight end faces and the rear end of the cylindrical drill body integrally formed on the same axis; the drill tip 7 is provided with a fro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com