Terylene carpet digital printing method

A processing method and printing technology, applied in dyeing, textiles and papermaking, etc., can solve problems such as immature selection of process parameters, achieve the effects of mass production capacity and quality improvement, optimized application, reduction of energy consumption and discharge of three wastes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

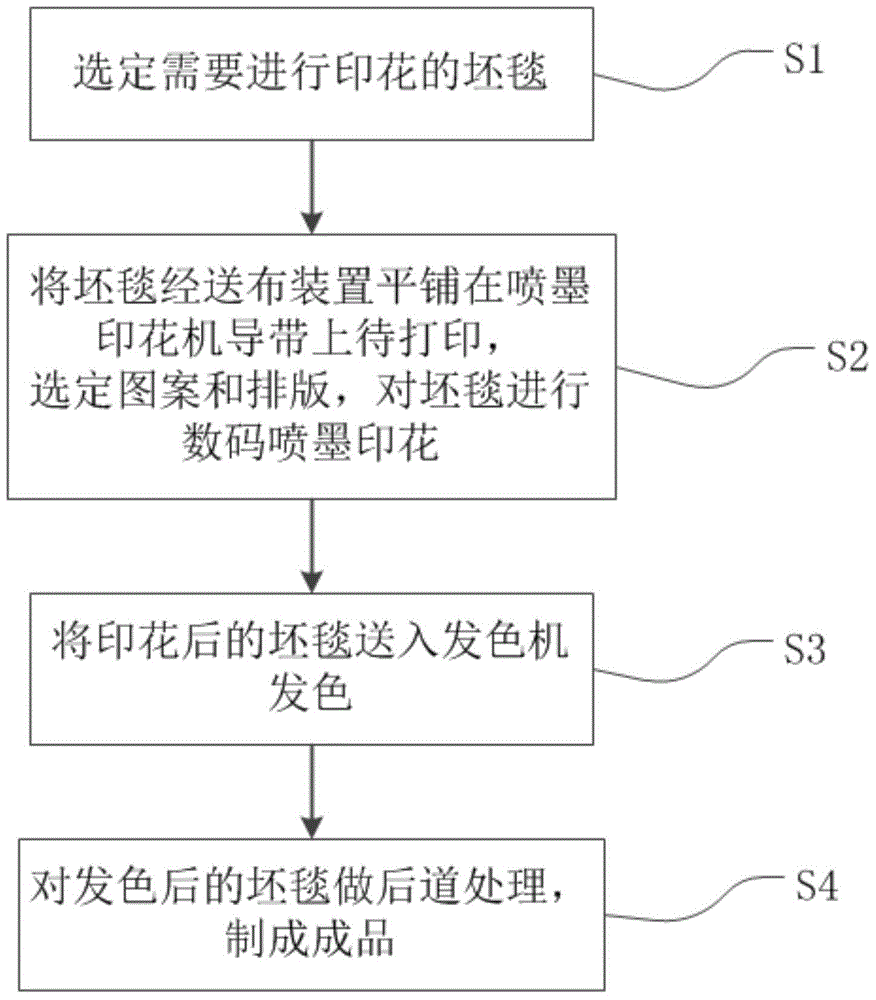

Method used

Image

Examples

Embodiment 1

[0024] The concrete steps of embodiment one are as follows:

[0025] Step 1. Prepare the blank blanket to be printed, which is made of modified polyester yarn, weaved by loop tufting machine, adhesive, quality inspection, and rolled. The specification of the blank blanket is polyester loop pile, and the weight is 280g / m 2 , cashmere height 4.0mm;

[0026] Step 2. Lay the above-mentioned polyester loop fleece blank on the guide belt of the inkjet printing machine through the cloth feeding device to be printed, preferably using a high-speed inkjet printing machine, and typesetting according to the size of the pattern to be printed, the width of the fabric, etc.; Set the printing parameters to 2Pass, precision 360*540DPI, and start printing.

[0027] Step 3. Send the printed fabric into the color hair machine, use infrared heating, set the color hair temperature to 185°C, and the speed to 1.0m / s to complete the color hair and color fixation process.

[0028] Step 4. After the c...

Embodiment 2

[0030] The concrete steps of embodiment two are as follows:

[0031] Step 1. Prepare the blank blanket to be printed, which is made of modified polyester yarn, weaved by loop tufting machine, adhesive, quality inspection, and rolled. The specification of the blank blanket is polyester loop pile, and the weight is 300g / m 2 , pile height 5.0mm;

[0032] Step 2. Lay the above-mentioned polyester loop fleece blank on the guide belt of the inkjet printing machine through the cloth feeding device to be printed, preferably using a high-speed inkjet printing machine, and typesetting according to the size of the pattern to be printed, the width of the fabric, etc.; Set the printing parameters to 3Pass, precision 360*720DPI, and start printing.

[0033] Step 3. Send the printed fabric into the coloring machine, use infrared heating, set the coloring temperature at 200°C, and the speed at 1.5m / s to complete the coloring and fixing process.

[0034] Step 4. After the color-developed fab...

Embodiment 3

[0036] The concrete steps of embodiment three are as follows:

[0037] Step 1. Prepare the blank blanket to be printed, which is made of modified polyester yarn, weaved by loop tufting machine, adhesive, quality inspection, and rolled. The specification of the blank blanket is polyester loop pile, and the weight is 290g / m 2 , pile height 4.5mm;

[0038] Step 2. Lay the above-mentioned polyester loop pile blank blanket on the guide belt of the inkjet printing machine through the cloth feeding device to be printed, preferably using a high-speed inkjet printing machine, and typesetting according to the size of the pattern to be printed, the width of the fabric, etc.; Set the printing parameters to 3Pass, precision 360*720DPI, and start printing.

[0039] Step 3. Send the printed fabric into the coloring machine, use infrared heating, set the coloring temperature at 195°C, and the speed at 1.2m / s, to complete the coloring and fixing process.

[0040] Step 4. After the color-deve...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Gram weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com