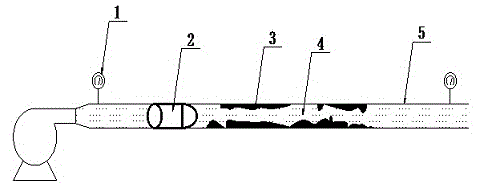

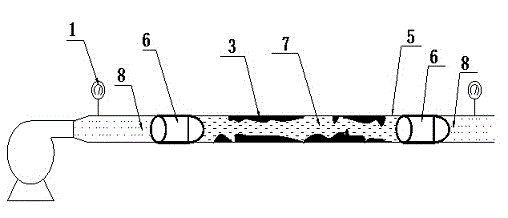

Pipeline targeted descaling method

A pipeline and targeted technology, applied in the field of descaling, can solve the problems of limited effect of dense scale layer, high cost, and pipeline blockage by pigs, and achieve the effects of efficient utilization, saving operating costs and reducing damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] In order to better understand the technical solutions of the present invention, the present invention will be further described in detail below in conjunction with the accompanying drawings and preferred embodiments.

[0013] The pigging ball is made of corrosion-resistant neoprene rubber. It is divided into two types: hollow ball and solid ball. The pigging ball with a pipe diameter greater than 100mm is a hollow ball, and a solid ball can be used when the pipe diameter is less than 100mm. The wall thickness of the hollow ball is one-tenth of the inner diameter of the pipe. The hollow ball is equipped with an air nozzle for inflation, and the hollow ball can also be filled with water. In winter, the ball should be filled with an aqueous solution of antifreeze (such as glycol) to prevent freezing. When the pigging ball runs in the pipeline, it is required to have a certain degree of sealing, so the outer diameter of the ball is required to be larger than the inner diame...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com