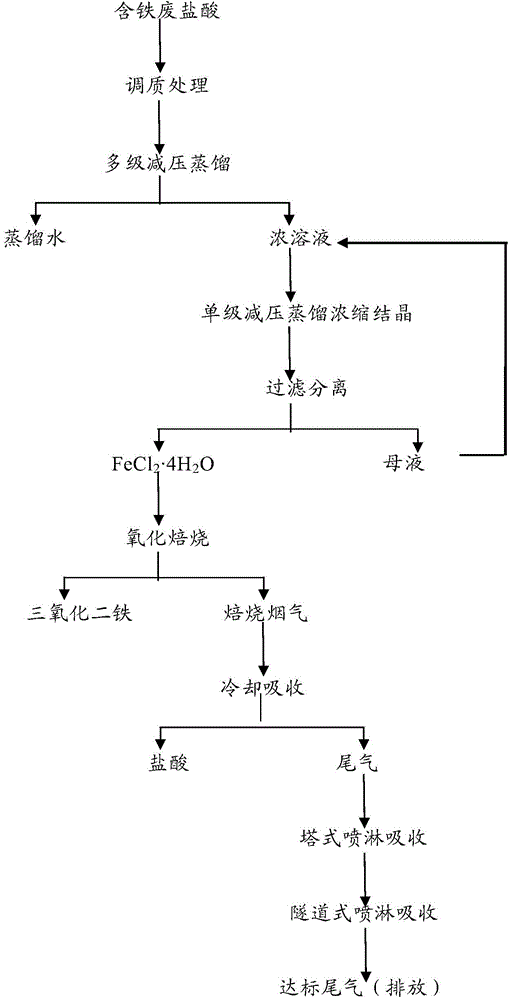

Treatment method of ferrous waste hydrochloric acid

A treatment method, waste hydrochloric acid technology, applied in separation methods, chemical instruments and methods, water/sewage multi-stage treatment, etc., can solve the problems of high equipment requirements, consumption, high temperature, etc., and achieve low operation requirements and low energy consumption , the effect of simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

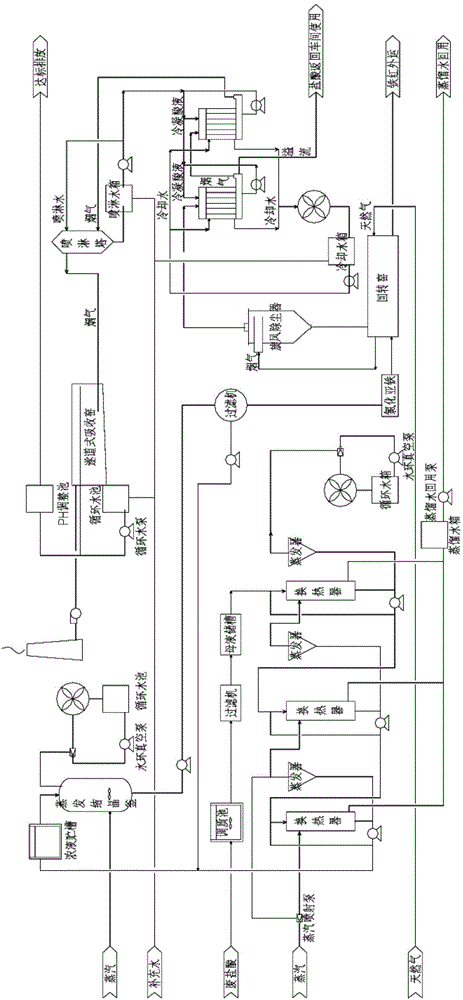

Method used

Image

Examples

Embodiment 1

[0071] First, the source of the iron-containing waste hydrochloric acid treated in this embodiment will be described.

[0072] A steel mill with an annual output of 1.7 million tons of carbon steel sheets, the main process facilities include pickling and continuous rolling unit, coiling unit, bell annealing furnace, skin pass unit, recoiling unit, continuous hot-dip galvanizing unit, packaging unit and its supporting equipment Public and auxiliary facilities. The production process uses 200g / L (5.5mol / L) hydrochloric acid to pickle the carbon steel sheet to remove the surface scale. The iron content (calculated as metallic iron) after pickling is about 120g / L (2.14mol Fe / L) , where Fe 3+ with Fe 2+ The ratio is 1:1, and the excess acidity is 0.15mol / L. The amount of waste hydrochloric acid produced in the production process is about 11m 3 / h, the temperature of waste hydrochloric acid is about 80°C.

[0073] Secondly, the following is the treatment process of iron-contain...

Embodiment 2

[0087] First, the source of the iron-containing waste hydrochloric acid treated in this embodiment will be described.

[0088] A 6 million tons plate production line, the pickling process produces 228,000 cubic meters of pickling solution per year. Based on an annual production day of 300 days, the daily processing is 760 cubic meters, and the processing is 31.7 cubic meters per hour. The concentration of pickling solution is 6.5mol / L, the concentration of metallic iron is 126.77g / L, Fe 3+ with Fe 2+ The ratio is 9:1, the excess H + The concentration is 0.15mol / L, and 228,000 cubic meters of pickling solution contains 28,900 tons of metallic iron.

[0089] Secondly, the following is the treatment process of iron-containing waste hydrochloric acid.

[0090] Use 1000 cubic meters of glass fiber reinforced plastic reaction tank as the tempering pool, and each glass fiber reinforced plastic reaction tank is equipped with a hydrogen discharge port and a liquid circulation pump....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com