Method and equipment for simultaneously crushing and grinding ores

A technology of ore and equipment, which is applied in the field of grinding methods and equipment, can solve the problems of non-continuous work, random blindness, and heavy repetitive workload, so as to avoid energy waste, protect from excessive wear, and reduce intermediate processes. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further explained below in conjunction with the accompanying drawings.

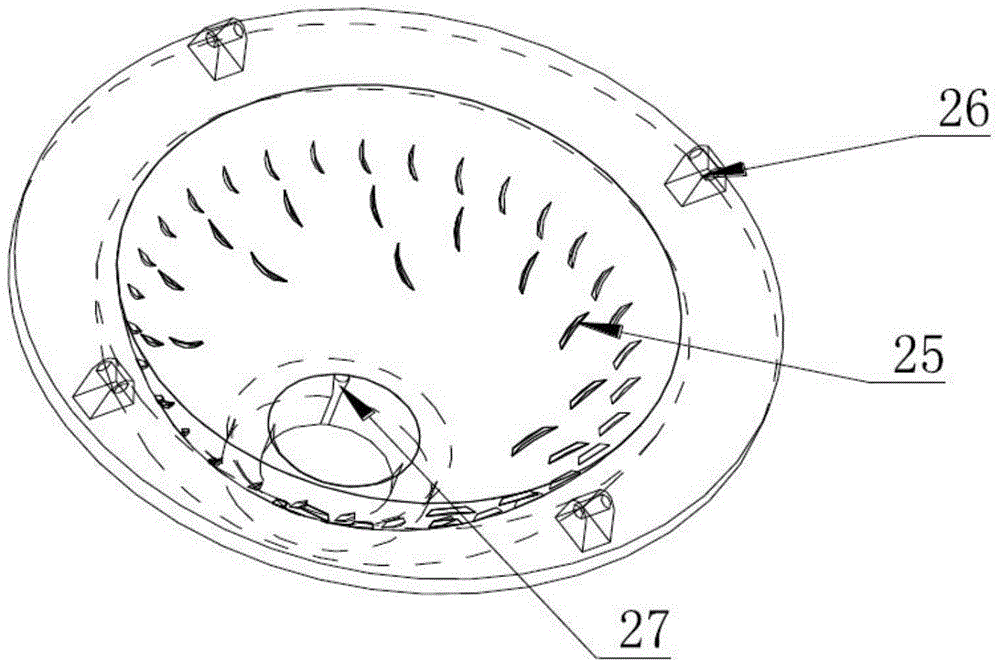

[0028] like figure 1 , 3 Shown in and 4, the method for simultaneously crushing and grinding ore of the present invention adopts an upper arc-shaped grinding surface 1 and a lower arc-shaped grinding surface 2, and the cross-sectional curves of the upper arc-shaped grinding surface 1 and the lower arc-shaped grinding surface 2 are parabolas, The function expression of the section curve of the upper arc grinding surface 1 is y=ax 2 , the function expression of the lower curved grinding surface 2 section curve is y=kax 2, In the above formula: y is the y-axis coordinate of the plane coordinate system, a is the quadratic term coefficient of the parabola, K is the proportional coefficient, x is the x-axis coordinate of the plane coordinate system, -0.8<a<-0.6, 1<k<1.2. The upper arc-shaped grinding surface 1 is superimposed on the lower arc-shaped grinding surface 2, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com