Device and method for recycling acrylonitrile gas

A recovery device and acrylonitrile technology, applied in separation methods, chemical instruments and methods, steam condensation, etc., can solve the problems of acrylonitrile gas polluting the environment, endangering the health of employees, and fire hazards, so as to prevent secondary pollution and structure Compact, small footprint effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

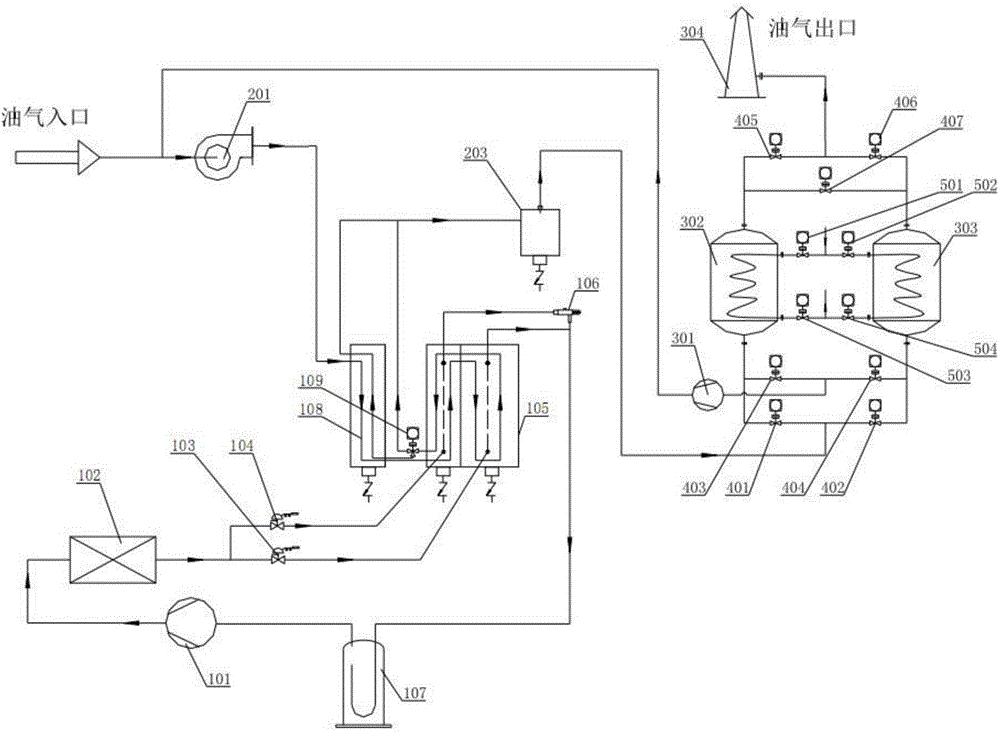

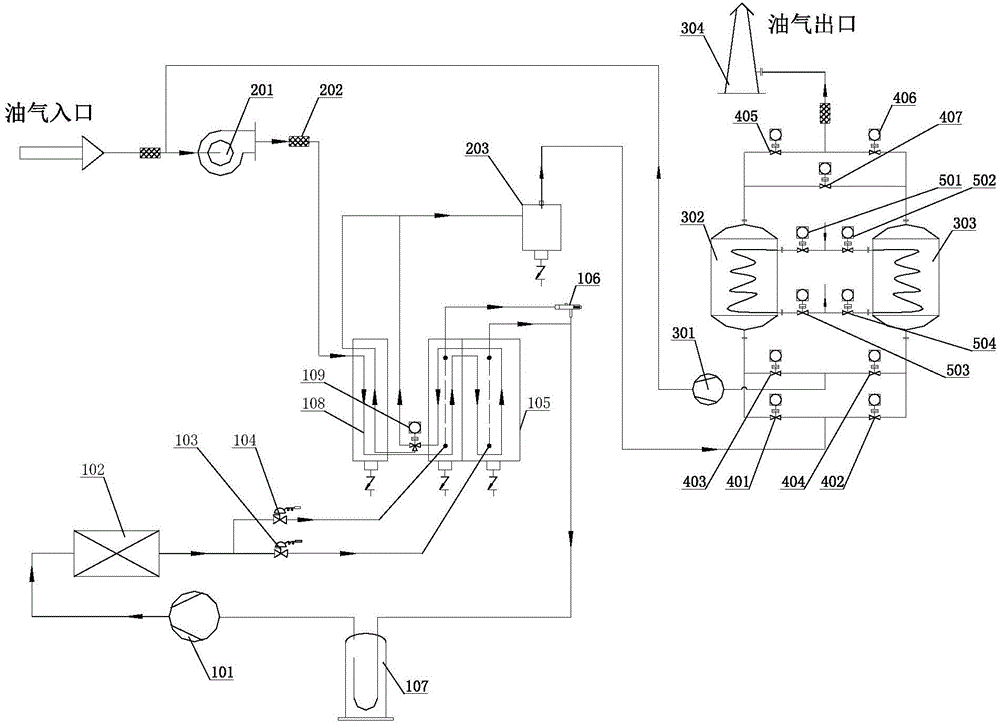

[0042] Embodiment 1: as figure 1 As shown, when the temperature swing pressure swing adsorption device is divided into two groups:

[0043] A recovery device for acrylonitrile gas, comprising a condensation circuit and a temperature-swing pressure-swing adsorption circuit, the condensation circuit comprising a refrigeration compressor 101, a condensation heat exchanger 102, a throttling element, a cold box heat exchanger 105, A gas-liquid separator 107, the gas-liquid separator 107 is connected to the refrigeration compressor 101; the bottom of the cold box heat exchanger 105 is provided with a liquid outlet;

[0044] The inlet of the oil and gas is connected to the inlet of the frequency conversion air pump 201, the outlet of the frequency conversion air pump 201 is connected to the inlet of the first air intake passage of the regenerative heat exchanger 108, and the outlet of the first air intake passage is connected to the outlet of the cold box heat exchanger 105. The inl...

Embodiment 2

[0052] Embodiment 2: The structure is basically the same as that of Embodiment 1, and the similarities are no longer repeated, and the difference is:

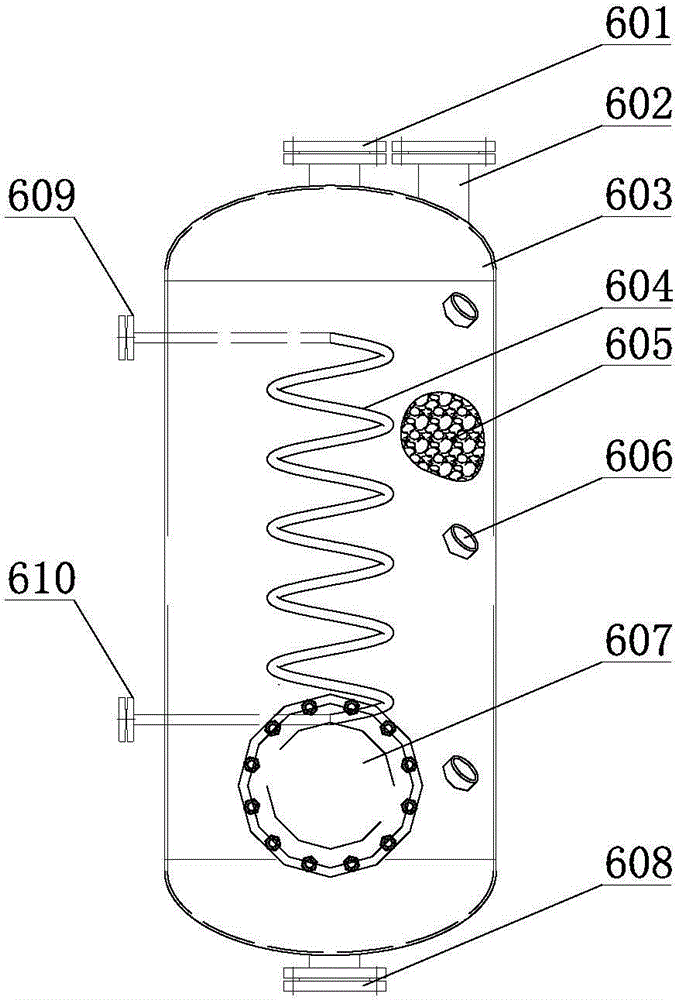

[0053] The cold box heat exchanger 105 is provided side by side with a first exchange room and a second exchange room, and the first exchange room includes a gas passage inlet, a gas passage outlet, a second air intake passage arranged in parallel in the longitudinal direction, and a second Return air channel; the second exchange chamber includes a third air intake channel and a third air return channel arranged in parallel longitudinally; The second air return channel and the outlet of the gas channel are connected to form a heat exchange channel; the liquid outlets are correspondingly opened at the bottom of the first exchange room and the second exchange room, and each liquid outlet is connected to the heat exchange channel.

[0054] The first exchange room also includes a first refrigerant pipeline parallel to the second ai...

Embodiment 3

[0056] Embodiment 3: the recovery method of the recovery device of the acrylonitrile gas described in embodiment 3 of the present invention, comprises the following steps:

[0057] ① Low-temperature condensation step: including the first low-temperature condensation step and the second low-temperature condensation step:

[0058] The first cryogenic condensation step:

[0059] The frequency conversion air pump sends the acrylonitrile gas into the cold box heat exchanger through the heat recovery heat exchanger, and the acrylonitrile gas is condensed in the cold box heat exchanger through the circulation cooling of the condensation circuit, and then the acrylonitrile gas is condensed through the switching of the three-way switching valve. , the condensed low-temperature acrylonitrile gas directly enters the anti-liquid sprinkler irrigation;

[0060] The second low-temperature condensation step: the frequency conversion air pump sends the acrylonitrile gas into the cold box heat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com