Piston type high-pressure feeding machine

A piston type and injection machine technology, applied in the field of injection equipment, can solve the problem that viscous materials cannot be quickly injected into the mold from bottom to top, and achieve the effects of reasonable structure design, accurate docking and positioning, and convenient use.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

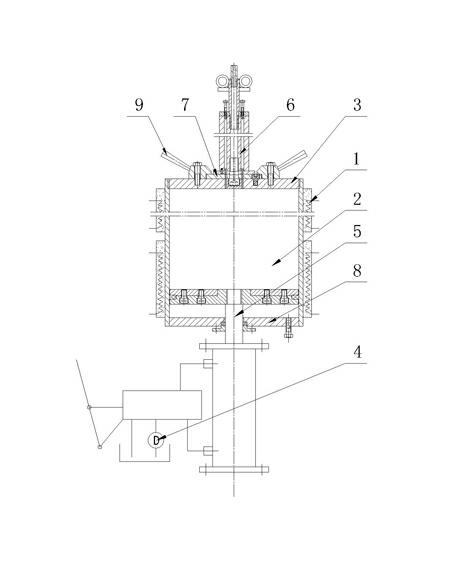

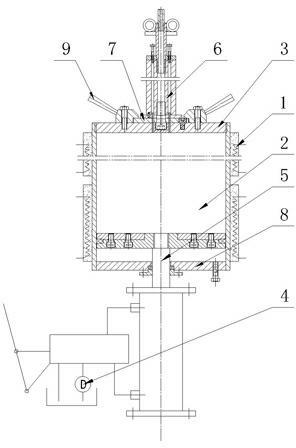

[0024] The accompanying drawings show embodiments of the present invention. In order to further illustrate the purpose and technical effects of the present invention, and to better understand the present invention, the embodiments of the present invention will be further described below in conjunction with the accompanying drawings, but the following descriptions should not be understood as a limitation of the present invention. The scope of protection of the present invention should be determined by the contents described in the claims.

[0025] The overall structure of this embodiment is as shown in the figure, which includes a cylinder body 2, a piston-type push rod 5 that is airtightly matched with its inner wall and can move linearly, and is opened in the opening at the front of the cylinder body 2; An end cap 3 threaded with the inner wall of the cylinder body 2 is fixed, an opening is opened on the end cap 3 and communicates with the inner cavity of the mold 6 , and a p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com