Water retention and purification blanket used for green roof and manufacturing method thereof

A water purification and integration technology, applied in the directions of botanical equipment and methods, applications, planting substrates, etc., can solve the problems of roof runoff water pollution, heavy metal organic pollutants exceeding the standard, falling on the roof, etc., and achieve prolonged and effective effects. Longevity, easy on-site paving, and the effect of drought resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

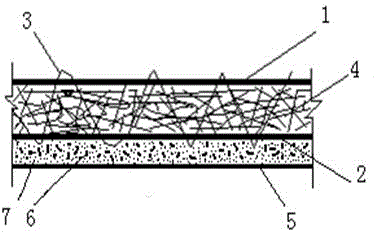

[0024] The rollable green roof water-retaining and water-purifying blanket in the present embodiment has a thickness of 20mm, a length of 5m, and a width of 3m; it includes upper, middle and lower layers of non-woven fabrics, and the upper and middle layers of non-woven fabrics. The fibers made of artificial synthetic materials in the middle have an attapulgite clay layer on the surface of the fibers; the thickness of the fiber layer between the upper and middle layers of non-woven fabrics is uniform; the thickness of uniform activated carbon particles and A blend of red algae powder.

[0025] Wherein, the non-woven fabric used is made of polypropylene material. The fiber adopts Coolplus fiber produced by Zhongxing Textile Co., Ltd. The attapulgite clay used is high-quality attapulgite mineral produced in Xuyi, Jiangsu Province, with a specific surface area of 350m 2 / g. In the mixture of activated carbon particles and red algae powder, activated carbon particles and red ...

Embodiment 2

[0033] The rollable green roof water-retaining and water-purifying blanket in the present embodiment has a thickness of 12mm, a length of 3m, and a width of 2m; it includes upper, middle and lower layers of non-woven fabrics, and the upper and middle layers of non-woven fabrics. The fibers made of artificial synthetic materials in the middle have an attapulgite clay layer on the surface of the fibers; the thickness of the fiber layer between the upper and middle layers of non-woven fabrics is uniform; the thickness of uniform activated carbon particles and A blend of red algae powder.

[0034] Wherein, the non-woven fabric used is made of polypropylene material. The fiber is Delight fiber from Nan Ya Plastic Industry Co., Ltd. The attapulgite clay used is high-quality attapulgite mineral produced in Xuyi, Jiangsu Province, with a specific surface area greater than 400m 2 / g. The activated carbon particles and red algae powder account for 30% and 70% (volume ratio) respectiv...

Embodiment 3

[0042] The curlable green roof water-retaining and water-purifying blanket in the present embodiment has a thickness of 8mm, a length of 2m, and a width of 1m; it includes upper, middle and lower layers of non-woven fabrics, and the upper and middle layers of non-woven fabrics. The fibers made of artificial synthetic materials in the middle have an attapulgite clay layer on the surface of the fibers; the thickness of the fiber layer between the upper and middle layers of non-woven fabrics is uniform; the thickness of uniform activated carbon particles and A blend of red algae powder.

[0043] Wherein, the non-woven fabric used is made of polypropylene material. The fiber adopts CoolMax fiber of DuPont Company. The attapulgite clay used is high-quality attapulgite mineral produced in Xuyi, Jiangsu Province, with a specific surface area greater than 450m 2 / g. The activated carbon particles and red algae powder account for 40% and 60% (volume ratio) respectively in the mixtur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com