Construction method of cast-in-situ bored pile suitable for karst cave geology

A technology of impact hole forming and construction method, which is applied in the direction of sheet pile walls, foundation structure engineering, construction, etc., and can solve problems that affect the safety of houses and personal property, the quality of pile foundations cannot be guaranteed, and the quality of pile foundations is endangered. Achieve the effects of avoiding later reinforcement or layer reduction events, improving pile-forming efficiency, and reducing the use of mud

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

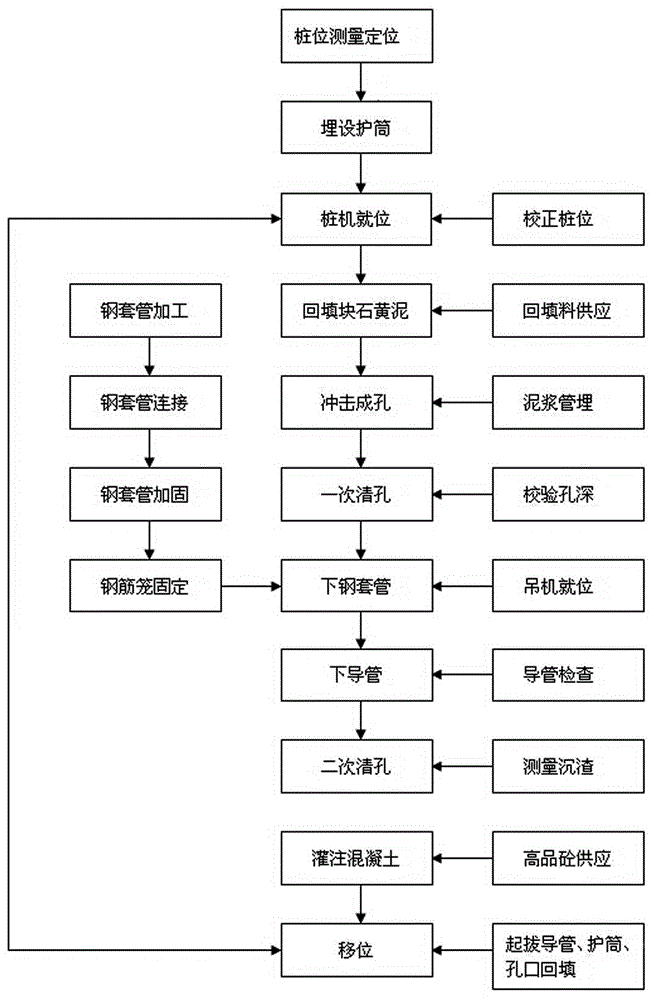

[0020] See attached picture. Present embodiment is example with design pile diameter 600mm, effective pile length 20m; It comprises the following steps:

[0021] 1) Pile position measurement and positioning; before determining the pile position, first re-calibrate the building base point, close the measurement, find out the relationship between the base point and the wire point, and then measure the pile position after meeting the error tolerance requirements; measure the pile position three times To carry out, measure once before digging and burying the casing, and re-measure once after burying the casing, so that the deviation between the center of the casing and the center of the pile site is not more than 50mm, and insert a long steel bar in the center of the pile location as a pile location mark; then use Use the level instrument to measure the floor elevation of the casing mouth, and make measurement records; the third measurement is to be carried out after the drilling ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com