Bioactive hollow nano-fibers and hollow microcapsules for efficiently catalyzing conversion of CO2 into methanol

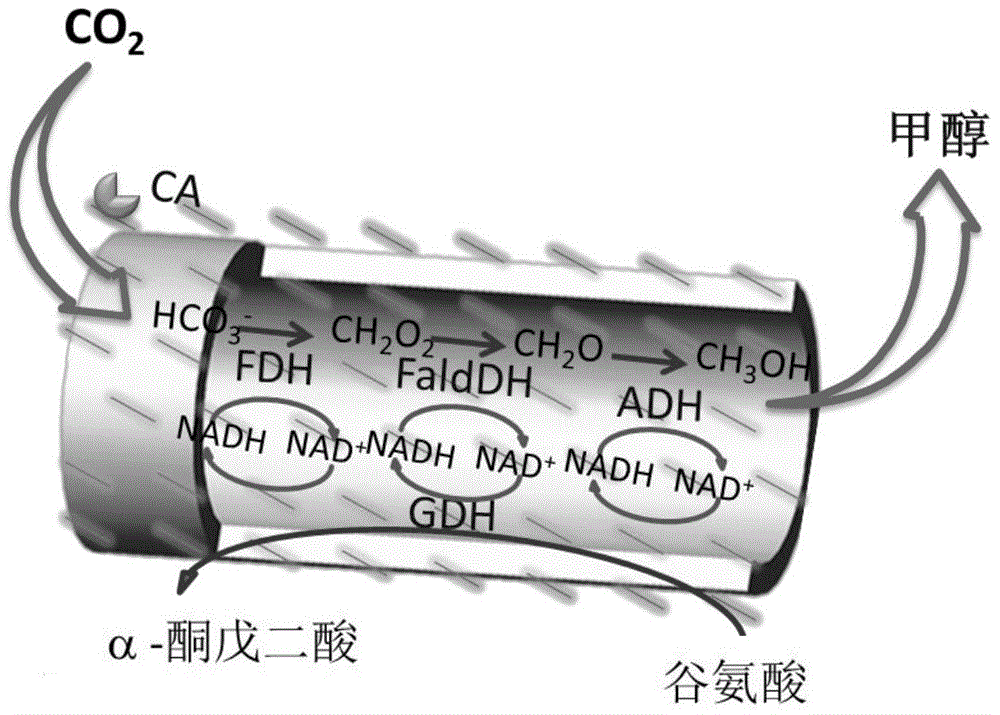

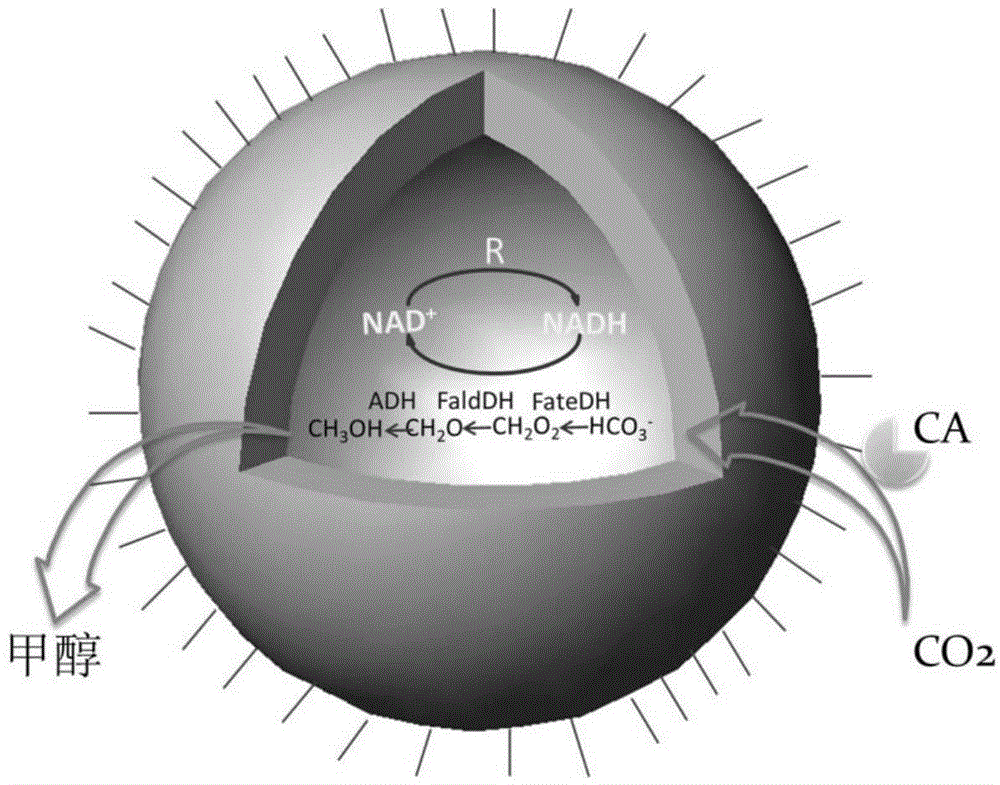

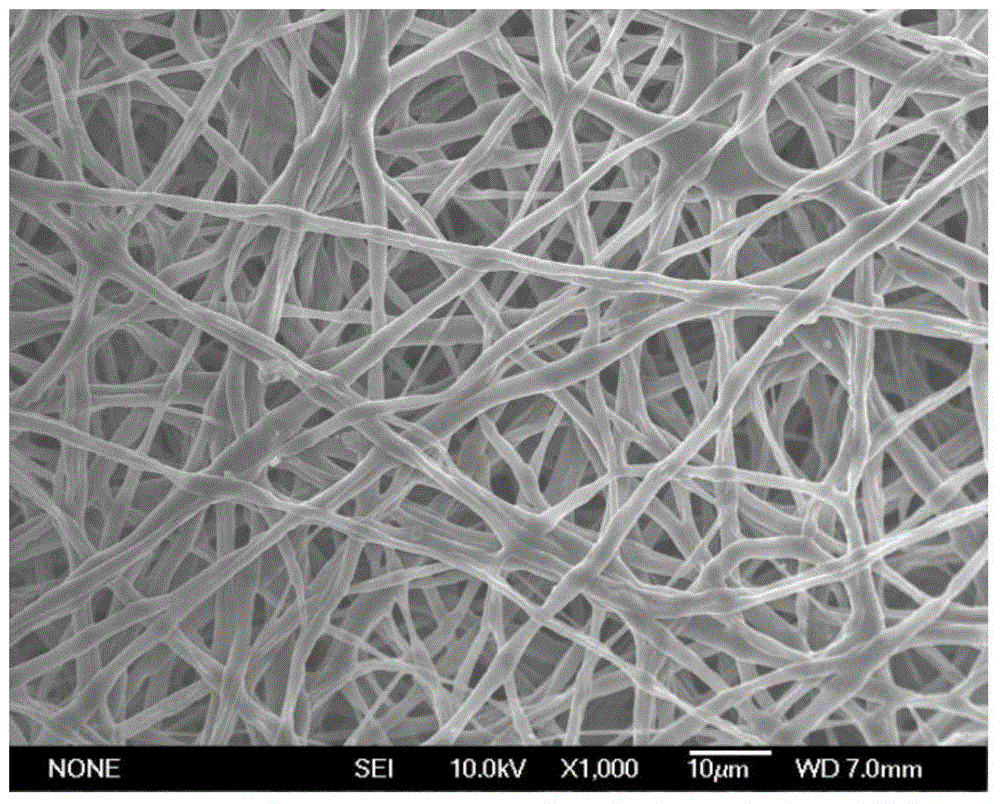

A nanofiber, biologically active technology, applied in the direction of fiber chemical characteristics, textiles and papermaking, conjugated synthetic polymer artificial filament, etc., can solve the problem of affecting the activity of immobilized multi-enzyme system, low load of multi-enzyme system, increased reaction cost and other issues, to achieve the effect of improving synergy and proximity effect, improving the overall catalytic efficiency, and accelerating the conversion speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] This example describes a method for CO in solution 2 Catalytic system for conversion to methanol, product detection method.

[0046] The content of each component in the catalytic reaction system is as follows: formate dehydrogenase: 0.5g / L; formaldehyde dehydrogenase: 0.5g / L; alcohol dehydrogenase: 0.5g / L; NADH: 1mmol / L; pH 7.0 Phosphate buffer: 50mM.

[0047] The reaction operation is as follows: First, CO was continuously introduced into 2 mL of phosphate buffer 2 Gas, add the multi-enzyme system of the above concentration, maintain the reactor pressure at 0.3MPa, 150rpm, and react at 37°C for 10 hours. Take out 20L of reaction solution at regular intervals, and use Agilent 7890A gas chromatography to detect the concentration of methanol generated .

Embodiment 2

[0049] This example describes a method for CO in solution 2 A catalytic system for converting to methanol, and a detection method for the product.

[0050] The content of each component in the catalytic reaction system is as follows: formate dehydrogenase: 0.5g / L; formaldehyde dehydrogenase: 0.5g / L; alcohol dehydrogenase: 0.5g / L; glutamate dehydrogenase: 0.5 g / L; NADH: 1 mmol / L; Phosphate buffer at pH 7.0: 50 mM.

[0051] The reaction operation is as follows: First, CO was continuously introduced into 2 mL of phosphate buffer 2 Gas, add the multi-enzyme system of the above concentration, maintain the reactor pressure at 0.3MPa, 150rpm, and react at 37°C for 10 hours. Take out 20μL of the reaction solution at regular intervals, and use Agilent 7890A gas chromatography to detect the concentration of methanol generated. .

Embodiment 3

[0053] This example describes a method for CO in solution 2 A catalytic system for converting to methanol, and a detection method for the product. The content of each component in the catalytic reaction system is as follows: carbonic anhydrase: 0.5g / L; formate dehydrogenase: 0.5g / L; formaldehyde dehydrogenase: 0.5g / L; alcohol dehydrogenase: 0.5g / L ; Glutamate dehydrogenase: 0.5g / L; NADH: 1mmol / L; Phosphate buffer at pH 7.0: 50mM.

[0054] The reaction operation is as follows: First, CO was continuously introduced into 2 mL of phosphate buffer 2 Gas, add the multi-enzyme system of the above concentration, maintain the reactor pressure at 0.3MPa, 150rpm, and react at 37°C for 10 hours. Take out 20L of reaction solution at regular intervals, and use Agilent 7890A gas chromatography to detect the concentration of methanol generated .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com