Cigarette alfalfa extract and preparation method thereof

A technology of alfalfa and extract, applied in tobacco, application, food science and other directions, to achieve the effect of improving aroma quality, simple equipment and easy large-scale production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

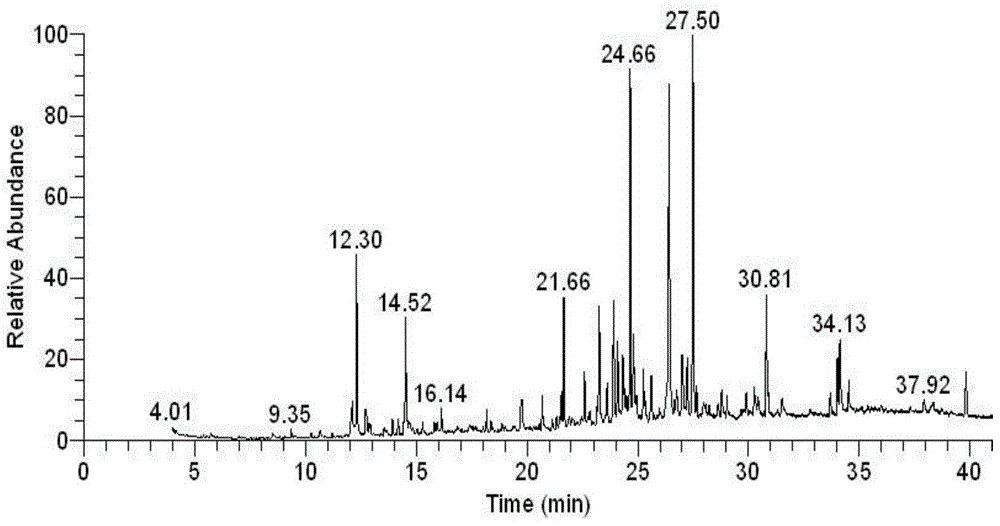

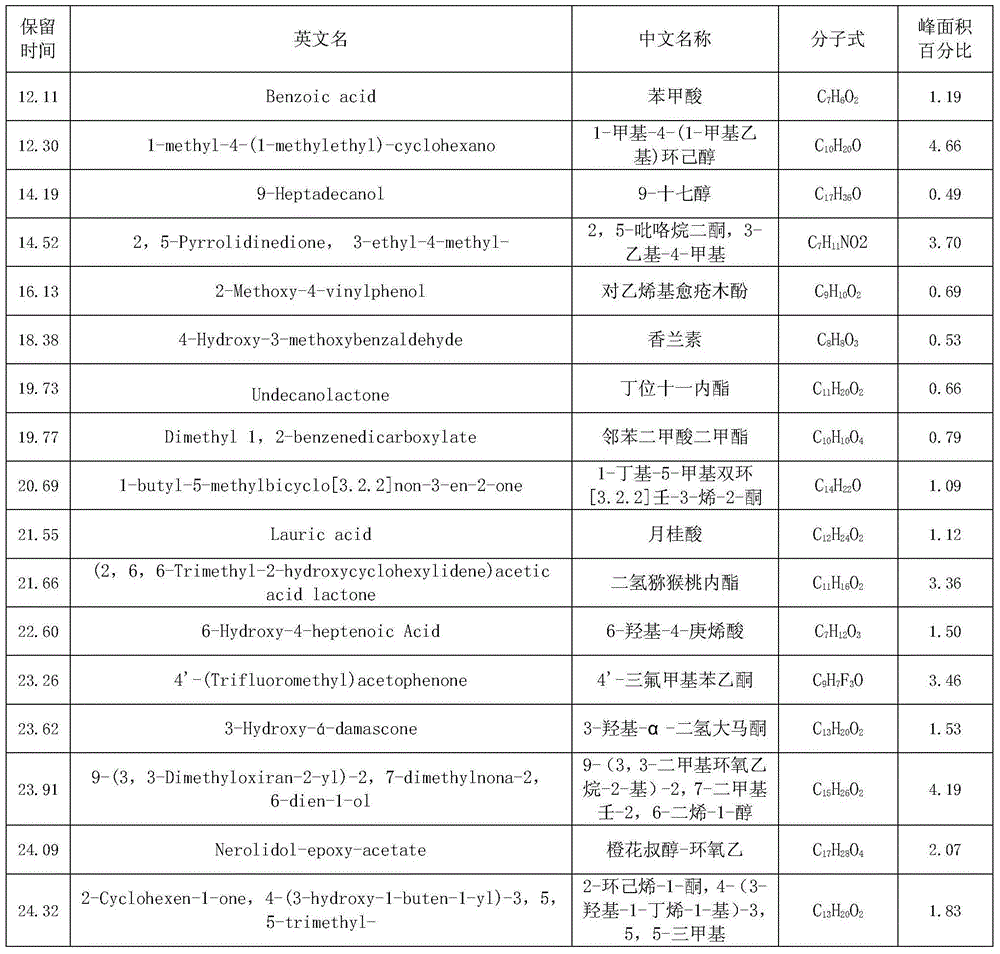

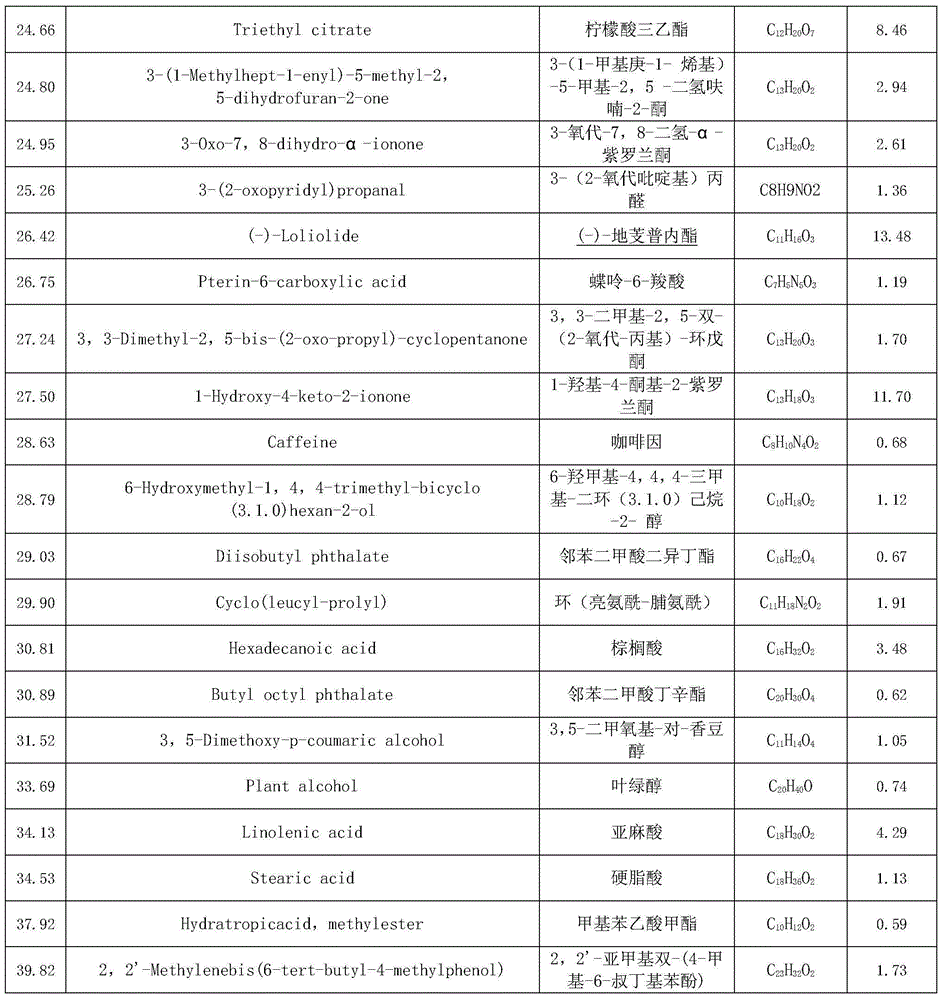

Image

Examples

Embodiment 1

[0023] (1) Pre-treatment: select alfalfa with good aroma and 30% water content, weigh 1KG, and cut into 1cm pieces.

[0024] (2) One-time extraction: use 10KG of 75% ethanol aqueous solution of the above-mentioned cut alfalfa to extract under reflux for 2 hours at 80° C., and separate the extract 1 after the extraction;

[0025] (3) Secondary extraction: use 80% ethanol aqueous solution of 8KG of the alfalfa raw material residue after the primary extraction, and carry out secondary reflux extraction at 80° C., the extraction time is 1 hour, and the extraction solution 2 is separated after the extraction;

[0026] (4) Coarse filtration: After mixing the extracts 1 and 2 separated twice, carry out coarse filtration with a 160-mesh screen;

[0027] (5) decolorization: add 10g of gac in the extract after the coarse filtration, leave standstill for 12 hours to decolorize;

[0028] (6) Concentration: Concentrate the decolorized extract at a temperature of 65°C and a vacuum of -0.08...

Embodiment 2

[0038] (1) Pre-treatment: select alfalfa with good aroma and 35% moisture content, weigh 1KG, and cut into 1.2cm sections;

[0039] (2) One-time extraction: use 6KG of the alfalfa after cutting above to contain 60% ethanol aqueous solution, reflux extraction at 100°C for 2.5 hours, and separate the extract 1 after the extraction;

[0040] (3) Secondary extraction: the alfalfa residue after the primary extraction was extracted with 4KG of 70% ethanol-containing aqueous solution for a secondary reflux extraction at 100° C., the extraction time was 2 hours, and the extraction solution 2 was separated after the extraction;

[0041] (4) Coarse filtration: After mixing the extracted solution 1 obtained twice with the extracted solution 2, carry out coarse filtration with a 160-mesh screen;

[0042] (5) decolorization: add 5g of gac in the obtained extract 3 after the coarse filtration, let it stand for 8 hours to decolorize;

[0043] (6) Concentration: Concentrate the decolorized e...

Embodiment 3

[0046] (1) Pre-treatment: select alfalfa with good aroma and 25% moisture content, weigh 1KG, and cut into 1.5cm sections;

[0047] (2) One-time extraction: use 8KG of 80% ethanol aqueous solution containing 80% ethanol to extract the above-mentioned cut alfalfa under reflux for 3 hours at 90° C., and separate the extract 1 after extraction;

[0048] (3) Secondary extraction: the alfalfa residue after the primary extraction was extracted with 6KG of 80% ethanol aqueous solution at 90°C for a secondary reflux extraction, the extraction time was 2 hours, and the extraction solution 2 was separated after the extraction;

[0049] (4) Coarse filtration: After mixing the extracted solution 1 obtained twice with the extracted solution 2, carry out coarse filtration with a 200-mesh screen to obtain the extracted solution 3;

[0050] (5) Decolorization: add 15g of gac to the extract 3 after the coarse filtration, let it stand for 12 hours to decolorize;

[0051] (6) Concentration: Con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com