Method for preparing cigarette essence containing aloe extractive and application of cigarette essence to cigarettes

A technology of aloe vera extract and tobacco flavor, which is applied in the extraction of tobacco flavor, the preparation of tobacco flavor, and the application of flavor in cigarettes. It can solve problems such as deficiencies, reduce injuries, correct inhalation, and improve cigarette quality. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

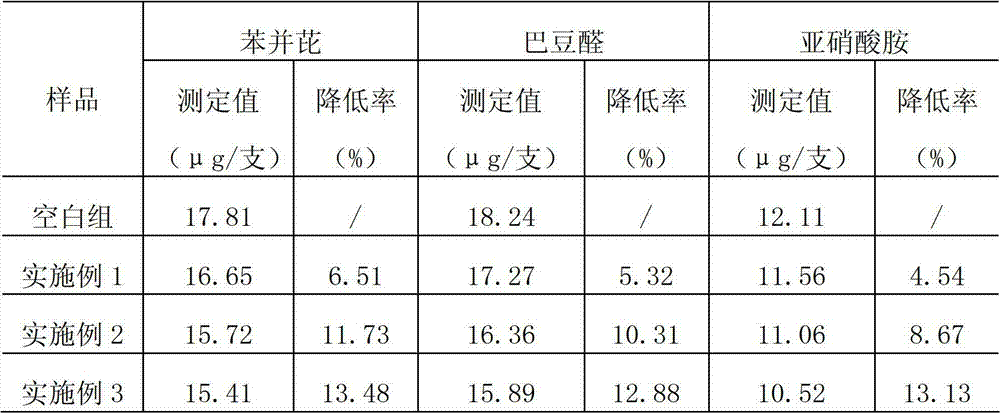

Embodiment 1

[0061] Take by weighing aloe sun-dried powder 100g, add 900g water in the ratio of aloe sun-dried powder and water mass ratio 1:9 to aloe sun-dried powder, extract at 35 ℃, centrifuge to obtain supernatant, concentrate then, obtain 500 g of concentrated supernatant.

[0062] 1-3 times the weight of the concentrated supernatant, add 500-1500 g of 95% ethanol by volume to the 500 g of the concentrated supernatant, refrigerate at a temperature of 2-4 ° C for 12 hours, then centrifuge, then filter, and obtain The obtained supernatant is then concentrated to obtain the aloe extract, which is in the form of a green paste.

[0063] Select SP825 resin, immerse it in 95% ethanol by volume, soak it for 24 hours, pack it into a column, wash it with water until it has no alcohol smell; weigh 1g of the aloe extract obtained above, stir it with water to dissolve it completely, and load it for adsorption.

[0064] Add 100g distilled water and clean in the resin of step (3); Add 100g 50% eth...

Embodiment 2

[0068] Take by weighing aloe sun-dried powder 100g, add 1200g water in the ratio of aloe sun-dried powder and water mass ratio 1:11 in the aloe sun-dried powder, extract at 35 ℃, centrifuge to obtain the supernatant, then concentrate to obtain 600 g of concentrated supernatant.

[0069] 1-3 times the weight of the concentrated supernatant, add 600-1800g 95% ethanol by volume to the 600g concentrated supernatant, refrigerate and stand at a temperature of 2-4°C for 24h, then centrifuge, then filter, and obtain The obtained supernatant is then concentrated to obtain the aloe extract, which is in the form of a green paste.

[0070] Select SP825 resin, immerse it in 95% ethanol by volume, soak it for 24 hours, pack it into a column, wash it with water until it has no alcohol smell; weigh 1g of the aloe extract obtained above, stir it with water to dissolve it completely, and load it for adsorption.

[0071] Add 100g distilled water and clean in the resin of step (3); Add 100g 50% ...

Embodiment 3

[0075] Take by weighing 100g of dried aloe powder, add 1000g water to the dried aloe powder in the ratio of 1:10 by the mass ratio of dried aloe powder and water, extract at 35°C, centrifuge to obtain the supernatant, then concentrate to obtain 550 g of concentrated supernatant.

[0076] 1-3 times the weight of the concentrated supernatant, add 550-1650 g of 95% ethanol by volume to the 550 g of the concentrated supernatant, refrigerate and stand for 18 hours at a temperature of 2-4 ° C, then centrifuge, then filter, and obtain The obtained supernatant is then concentrated to obtain the aloe extract, which is in the form of a green paste.

[0077] Select SP825 resin, immerse it in 95% ethanol by volume, soak it for 24 hours, pack it into a column, wash it with water until it has no alcohol smell; weigh 1g of the aloe extract obtained above, stir it with water to dissolve it completely, and load it for adsorption.

[0078] Add 100g distilled water and clean in the resin of ste...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com