Ultraviolet curing anti-anodic oxidation shielding protection printing ink

A technology for protecting ink and ultraviolet light, applied in ink, household utensils, applications, etc., can solve the problems of low film protection process efficiency, low product yield, and incompetence, and achieve excellent film release performance, fast curing speed, and attached Good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0060] Raw materials: based on the total weight of the ink, anhydride-modified epoxy acrylate 15%; aliphatic urethane acrylate 30%; aromatic urethane acrylate 25%; hydroxyethyl acrylate 10%; 1-hydroxy-cyclohexyl benzophenone 3%; 2,4,6-trimethylbenzoyl-diphenylphosphine oxide 1.5%; talc 15%; phthalocyanine blue 0.5%; polyether modified polydimethylsiloxane 0.3%.

[0061] Preparation method: Step 1: Stir the raw materials in the above ratio with a disperser for 1.5 hours to dissolve the initiator and mix the materials evenly; Step 2: Filter the product obtained in Step 1 to obtain the finished product.

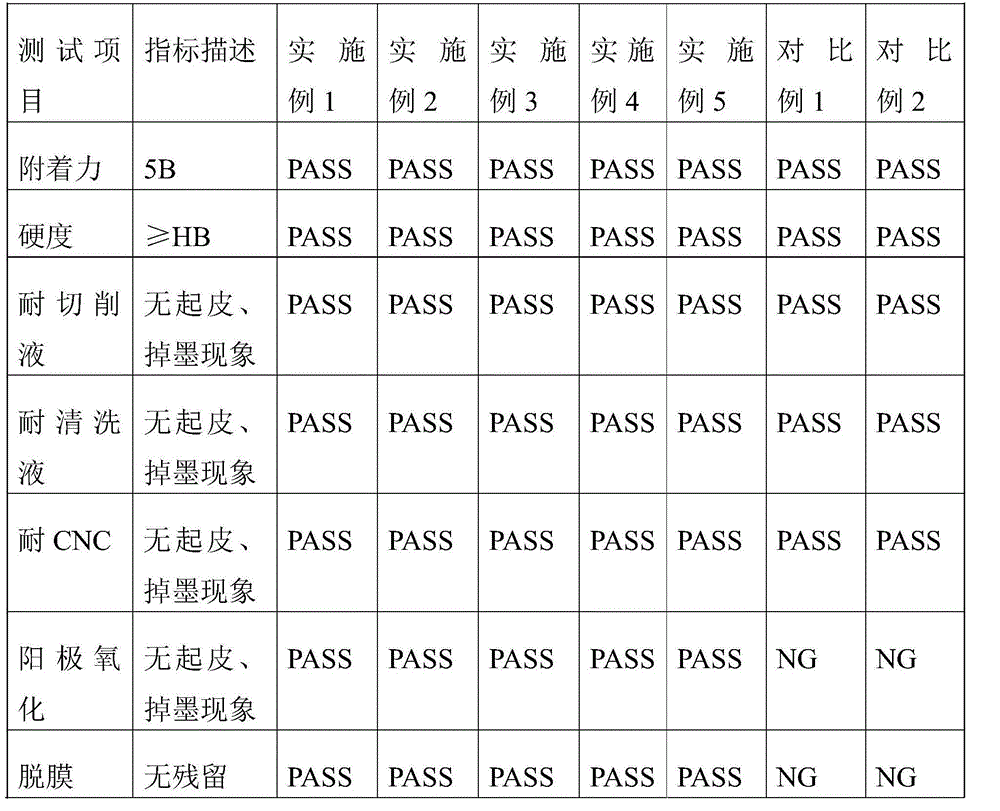

[0062] The product hardness HB was measured, and the adhesion force was 5B. The test performance is shown in Table 1.

Embodiment 2

[0064] Raw materials: based on the total weight of the ink, 20% of anhydride-modified epoxy acrylate; 50% of aliphatic urethane acrylate derived from caprolactone long-chain polyol; 5% of aromatic urethane acrylate; 5% of isobornyl acrylate; Acrylate Phosphate 0.5%; 1-Hydroxy-Cyclohexylbenzophenone 3%; 2,4,6-Trimethylbenzoyl-Diphenylphosphine Oxide 1%; Talc 15%; Phthalocyanine Blue 0.5% ; Polyether modified polydimethylsiloxane 0.3%.

[0065] Step 1: Stir the raw materials in the above ratio with a disperser for 1.5 hours to dissolve the initiator and mix the materials evenly; Step 2: Filter the product obtained in Step 1 to obtain the finished product.

[0066] The product hardness HB was measured, and the adhesion force was 5B. The test performance is shown in Table 1.

Embodiment 3

[0068] Raw materials: 40% aliphatic urethane acrylate derived from tetrahydrofuran long-chain polyols; 20% anhydride-modified epoxy acrylate; 15% isobornyl acrylate; 1-hydroxy-cyclohexylbenzophenone, based on the total weight of the ink 2%; 2,4,6-trimethylbenzoyl-diphenylphosphine oxide 1.5%; talc 20%; phthalocyanine blue 0.5%; aminomethoxysilane 1%; base siloxane 0.3%.

[0069] Step 1: Stir the raw materials in the above ratio with a disperser for 1.5 hours to dissolve the initiator and mix the materials evenly; Step 2: Filter the product obtained in Step 1 to obtain the finished product.

[0070] The product hardness HB was measured, and the adhesion force was 5B. The test performance is shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Functional group degree | aaaaa | aaaaa |

| adhesivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com