Preparation method of novel cement-based plant straw fiber particle wall material

A technology of plant straw and wall materials, which is applied in the field of building materials, can solve the problems of failure to meet the requirements of load-bearing walls and low compressive strength, achieve excellent sound insulation performance and effect, improve thermal insulation performance, and improve calculation Effects of weighted sound insulation and spectrum correction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

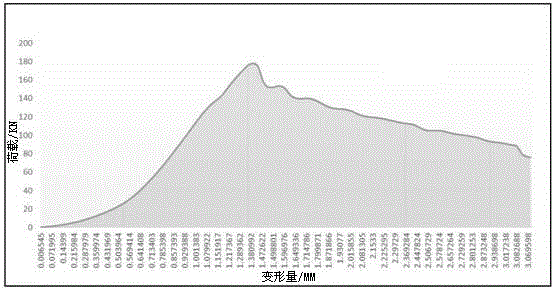

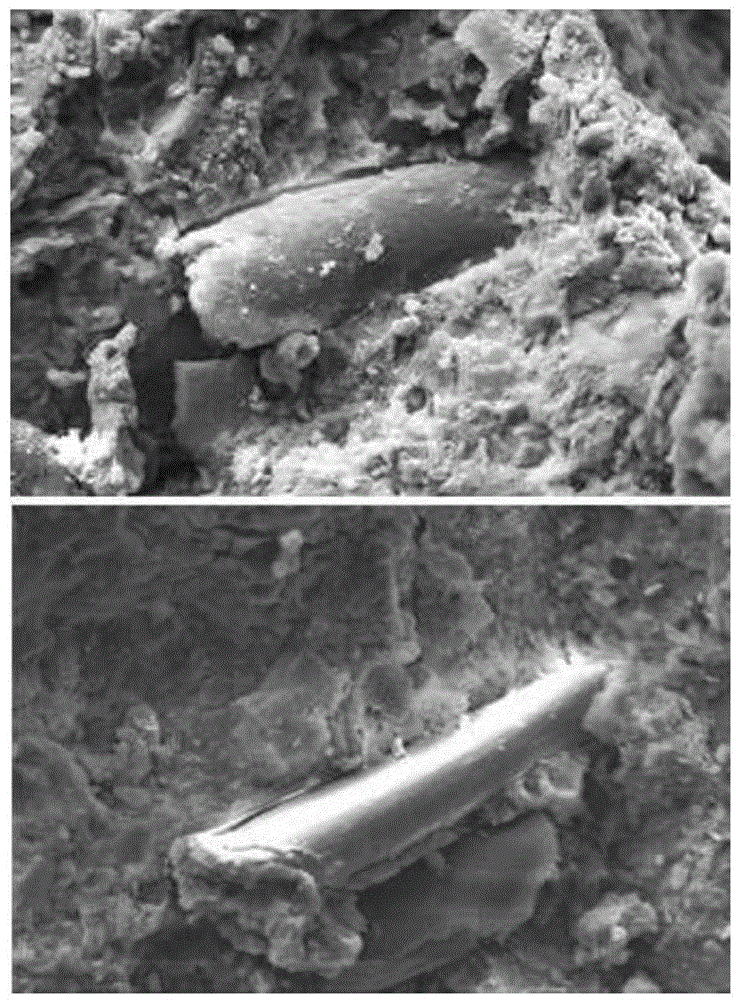

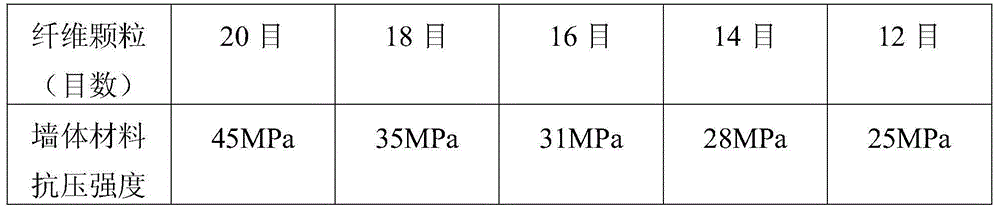

[0035] Step 1. Cut the dried wheat straw fibers into small sections of 3 to 5 mm, then soak them in 3% sodium hydroxide solution for 5 hours for surface modification treatment, and then dry them in the air; The fan and the crushing host suck the dried wheat straw fibers into the grinder from the feed port, and control the frequency of the crushing host to 10Hz, the frequency of the induced draft fan to 20Hz, and the frequency of the classifier to 25Hz; stop feeding after 5 minutes of continuous feeding, and Continue to pulverize for 5 minutes to obtain wheat straw fiber particles;

[0036] Step 2, using a 20 mesh / mesh square hole sieve to sieve the wheat straw fiber particles obtained in step 1 to obtain wheat straw fiber particles with a particle size of 20 mesh;

[0037] Step 3: Take 100 parts of 32.5R grade ordinary Portland cement, 40 parts of fly ash, 10 parts of fine sand, 5 parts of 20-mesh wheat straw fiber particles, and 30 parts of water according to the weight perce...

Embodiment 2

[0039] Step 1: Cut the dried wheat straw fibers into small sections of 3 to 5 mm, then soak them in 5% sodium hydroxide solution for 10 hours for surface modification treatment, and then dry them in the air; open the classifier of the straw crusher, Fan and crushing host, suck the dried wheat straw fibers into the pulverizer from the feed port, and control the frequency of the crushing host to 20Hz, the frequency of the induced draft fan to 40Hz, and the frequency of the classifier to 35Hz; stop feeding after 8 minutes of continuous feeding, and Continue to pulverize for 10 minutes to obtain wheat straw fiber particles;

[0040] Step 2, using a square hole sieve of 80 mesh / mesh to sieve the wheat straw fiber particles obtained in step 1 to obtain wheat straw fiber particles with a particle size of 80 mesh;

[0041] Step 3: Take 100 parts of 42.5 grade ordinary Portland cement, 50 parts of fly ash, 30 parts of fine sand, 15 parts of 80-mesh wheat straw fiber particles, and 40 p...

Embodiment 3

[0043] Step 1. Cut the dried corn stalk fibers into small sections of 3 to 5 mm, then soak them in 4% potassium hydroxide solution for 8 hours for surface modification treatment, and then dry them in the air; Fan and crushing host, suck the dried corn stalk fiber into the grinder from the feed port, and control the frequency of the crushing host to 15Hz, the frequency of the induced draft fan to 25Hz, and the frequency of the classifier to 30Hz; stop feeding after 8 minutes of continuous feeding, and Continue to pulverize for 8 minutes to obtain corn stalk fiber particles;

[0044] Step 2, using a 60 mesh / mesh square hole sieve to sieve the corn stalk fiber particles obtained in step 1 to obtain corn stalk fiber particles with a particle size of 60 mesh;

[0045] Step 3: Take 100 parts of 32.5R grade ordinary Portland cement, 48 parts of fly ash, 25 parts of fine sand, 10 parts of 60-mesh corn stalk fiber particles, and 35 parts of water according to the weight percentage, ful...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com