Load-type nano zero-valence iron particle and preparation method therefor

A nano-zero-valent iron, load-type technology, applied in the fields of nanotechnology, nanotechnology, nanotechnology for materials and surface science, can solve the problem of uneven particle size distribution of nano-zero-valent iron particles, low reactivity, and ease of use. Problems such as agglomeration occur, and the effect of small particle size distribution range, uniform distribution and low price is achieved.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] A loaded nanometer zero-valent iron particle uses modified sepiolite as a carrier, and the surface and interior of the modified sepiolite carrier are loaded with nanometer zero-valent iron particles. The preparation process specifically includes the following steps:

[0039] (1) Preparation of modified sepiolite

[0040]Add 15% hydrochloric acid aqueous solution to natural sepiolite powder, then fully mix and stir at 25-30°C for 48 hours, then wash with deoxygenated deionized water until the effluent is neutral, and then control the temperature to 115- Dry at 125°C, then control the temperature to 310-330°C for roasting, then grind, pass through a 160-200 mesh sieve, and the obtained powder is modified sepiolite;

[0041] The amount of hydrochloric acid aqueous solution with a mass percentage concentration of 15% is calculated by mass ratio, that is, natural sepiolite powder: the mass percentage concentration of 15% hydrochloric acid aqueous solution is 1:5;

[0042] (...

Embodiment 2

[0059] A loaded nano-sized zero-valent iron particle, using modified sepiolite as a carrier, the surface and inside of the modified sepiolite carrier are loaded with nano-sized zero-valent iron particles, and the preparation process excludes the step (3) NaBH with a concentration of 0.4mol / L 4 The aqueous solution uses KBH with a concentration of 0.4mol / L 4 Aqueous solution replaces, and others are all the same as embodiment 1.

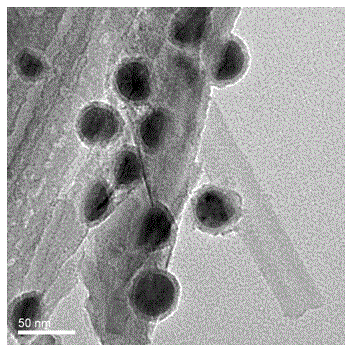

[0060] Using a transmission electron microscope (JEM 2011, Jeol, Japan) to measure the above-mentioned loaded nano-zero-valent iron particles, it can be concluded that the particle size of the nano-zero-valent iron particles loaded on the surface of the modified sepiolite carrier The diameter of the nanometer zero-valent iron particles loaded inside the modified sepiolite is about 0.01-1nm.

Embodiment 3

[0062] A loaded nanometer zero-valent iron particle uses modified sepiolite as a carrier, and the surface and interior of the modified sepiolite carrier are loaded with nanometer zero-valent iron particles. The preparation process specifically includes the following steps:

[0063] (1) Preparation of modified sepiolite

[0064] Add 15% hydrochloric acid aqueous solution to natural sepiolite powder, then fully mix and stir at 25-30°C for 48 hours, then wash with deoxygenated deionized water until the effluent is neutral, and then control the temperature to 115°C Drying, then controlling the temperature to 320°C for roasting, then grinding, passing through a 160 mesh sieve, the obtained powder is modified sepiolite;

[0065] Mass percent concentration is the consumption of 15% hydrochloric acid aqueous solution, calculates by mass ratio, i.e. natural sepiolite powder: mass percent concentration is 15% hydrochloric acid aqueous solution is 1:5;

[0066] (2) Preparation of modifi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com