Coated nickel hydroxide powder for alkali secondary battery positive electrode active material and method of producing same

A positive electrode active material, nickel hydroxide technology, applied in the field of nickel hydroxide powder and its manufacturing, can solve the problems of no effective solution for paste dispersibility, unsatisfactory foamed nickel filling density, etc., to achieve high The effect of densification

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0084] (Crystalization process)

[0085] After dissolving 134.3 kg of industrial-use nickel sulfate hexahydrate, 4.6 kg of industrial-use cobalt sulfate heptahydrate, and 4.0 kg of magnesium sulfate in water, the total amount was adjusted to 300 L to prepare a nickel-containing aqueous solution. Separately, 100 L of a 48% by mass industrial sodium hydroxide solution was diluted with water to prepare a total of 200 L of an aqueous sodium hydroxide solution.

[0086] Next, after filling the reaction tank with a capacity of 9 L up to the overflow port with water, the reaction tank was placed in a constant temperature water tank, and the temperature was adjusted to 50° C. and kept warm. And, while stirring in the reaction tank, continuously supply the above-mentioned nickel-containing aqueous solution and industrial 25% by mass ammoniacal liquor in the reaction tank, at the same time, adopt a pH controller, and utilize the above-mentioned sodium hydroxide solution to adjust the pH...

Embodiment 2

[0097] Cobalt oxyhydroxide-coated Nickel hydroxide powder.

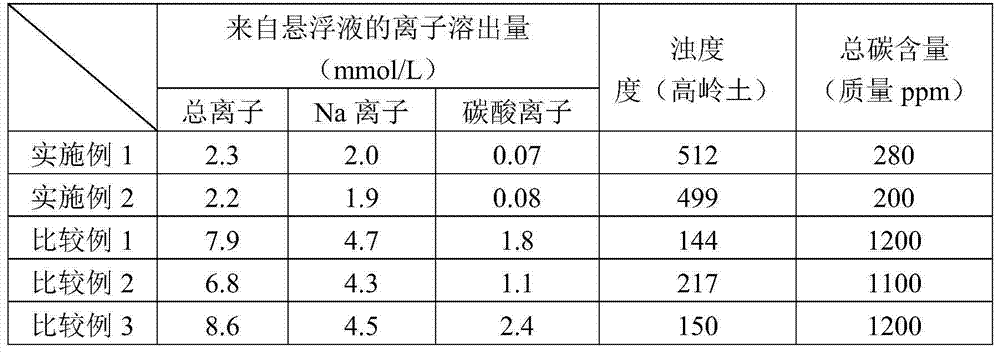

[0098] In the obtained cobalt oxyhydroxide-coated nickel hydroxide powder, the total amount of ions eluted in the suspension was 2.2 mmol / L. In addition, the eluted amounts of sodium ions and sulfate ions were 1.9 mmol / L and 0.08 mmol / L, respectively. The turbidity of the suspension was 499 degrees (kaolin).

[0099] In addition, the total carbon content of the obtained cobalt oxyhydroxide-coated nickel hydroxide powder was 200 ppm. The above measurement results are shown in Table 1 below.

PUM

| Property | Measurement | Unit |

|---|---|---|

| actual density | aaaaa | aaaaa |

| actual density | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com