Copper alloy hot-rolled plate for sputtering target and sputtering target

A copper alloy and hot-rolled plate technology, which is applied in metal rolling, sputtering coating, metal material coating technology, etc., can solve the problem that the crystal grain size of Cu-α phase is easy to increase, and the crystal grain size is not considered. problem, achieve the effect of preventing the generation of particles and suppressing abnormal discharge

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

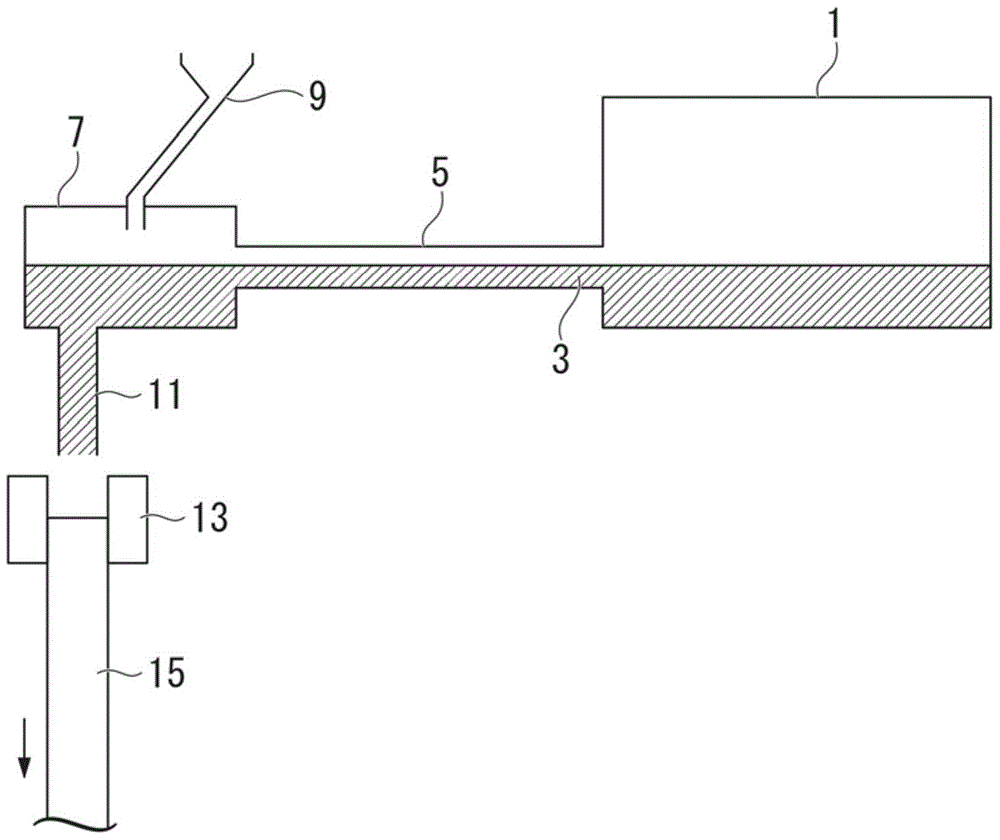

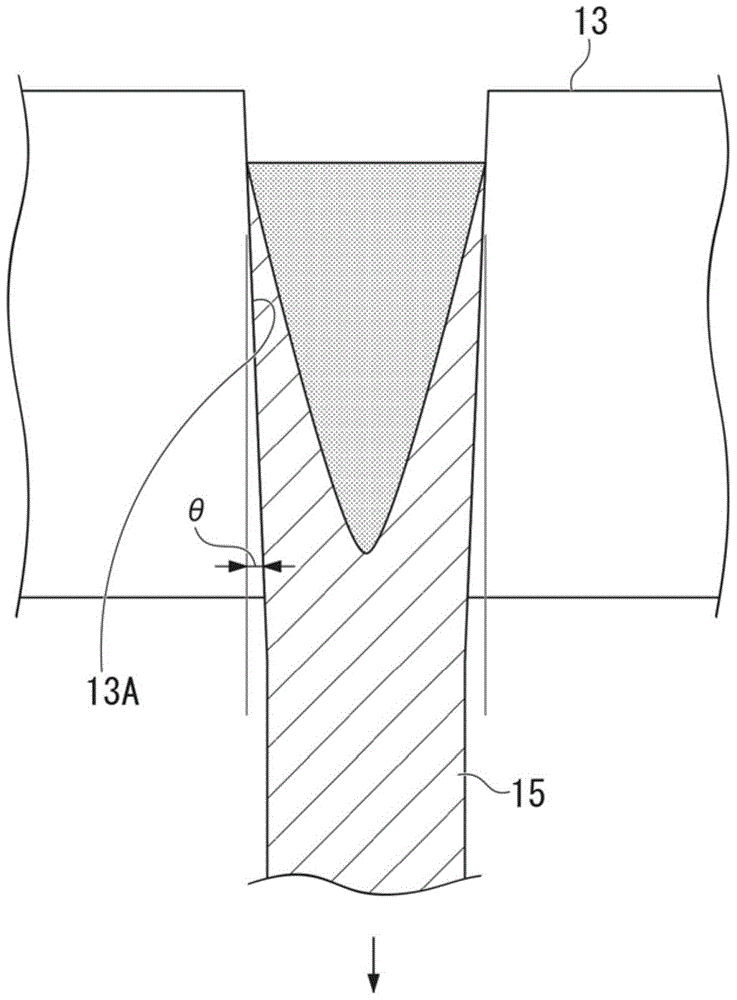

[0074] use figure 1 The continuous casting device shown melts electrolytic copper with a purity of 99.99% by mass, and adds Ca to the molten copper through the addition mechanism 9, thereby casting No.1 to No.9 and No. 9 of the present invention examples in Table 1. A Cu—Ca-based alloy having the composition shown in No. 10 of the comparative example. The ingot was constituted as a cake-shaped ingot having a rectangular cross-section of 260 mm×640 mm. In addition, a carbon mold was used as a casting mold at the time of casting, and the amount of cooling water was set at 2,500 liters / minute. In addition, the tapered surface of the mold was set at 0.4° on the long side and 0.4° on the short side. The withdrawal speed was set at about 9 cm / min.

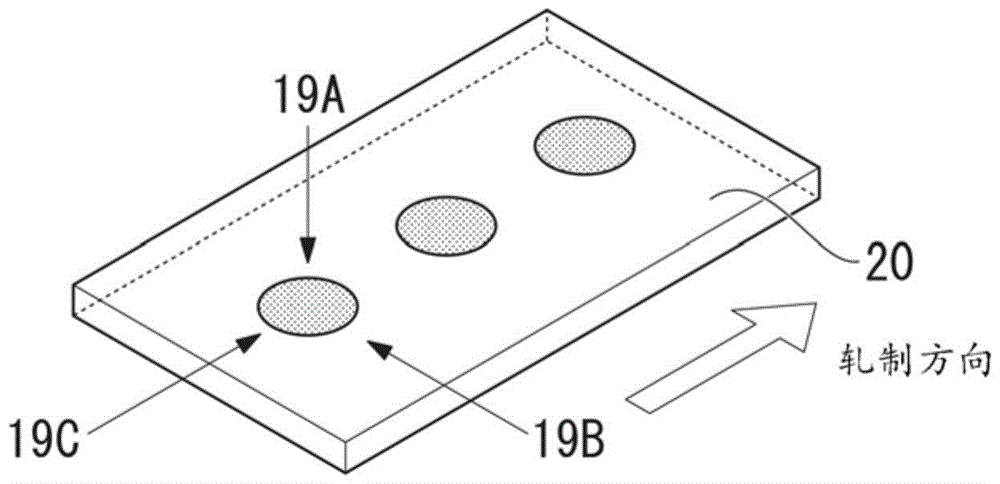

[0075] The casted continuous casting ingot was divided into lengths of 950 mm, heated in a batch heating furnace at the hot rolling starting temperature described in Table 1 for 2 hours, and then hot rolling was started, and the rolli...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com