One-pot method for the synthesis of cu-ssz-13, the compound obtained by the method and use thereof

A technology of cu-ssz-13 and mixture, applied in molecular sieves and base exchange compounds, separation methods, chemical instruments and methods, etc., can solve problems such as uncontrollable Si/Al ratio and Cu content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0055] Embodiment 1: Synthesis of N, N, N-trimethyl-1-adamantyl ammonium

[0056] 29.6 grams of 1-adamantanamine (Sigma-Aldrich) and 64 grams of potassium carbonate (Sigma-Aldrich) were mixed with 320 ml of chloroform. At this point, 75 g of iodomethane was added dropwise while the reaction was stirring in an ice bath. The reaction was kept under stirring at room temperature during the 5 days. The mixture was filtered and washed with diethyl ether, and the resulting solid was further extracted with chloroform. The final product is N,N,N-trimethyl-1-adamantyl ammonium iodide. The iodide salt is anion exchanged with an ion exchange resin to obtain the hydroxide form.

Embodiment 2

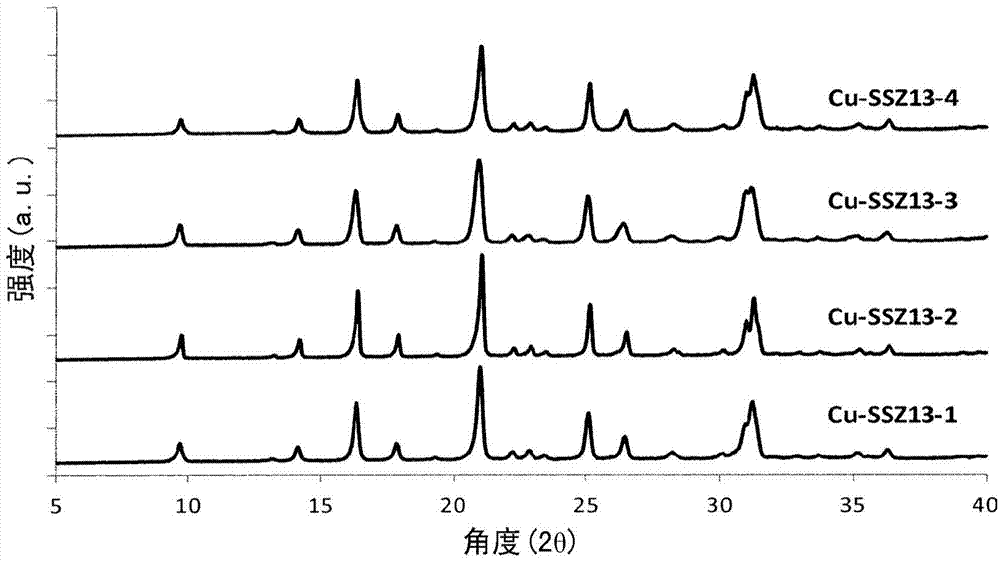

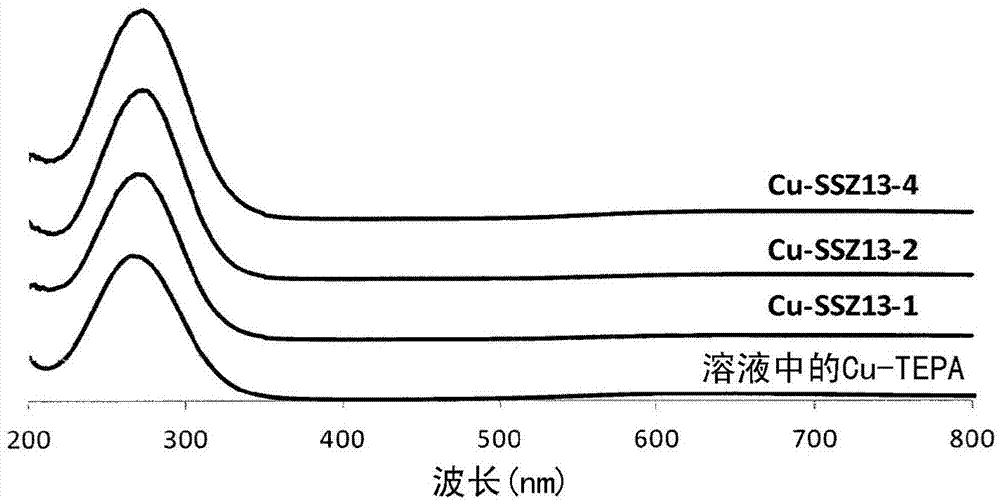

[0057] Example 2: Direct synthesis of "Cu-SSZ13-1" in OH medium

[0058] 159 mg of a 20 wt% aqueous solution of copper(II) sulfate (98 wt%, Alfa) was mixed with 36 mg of tetraethylenepentamine (TEPA, 99 wt%, Aldrich) and kept stirring for 2 hours. Subsequently, 1041 mg of an aqueous solution of N,N,N-trimethyl-1-adamantyl ammonium hydroxide (TMaDA, 16% by weight) and 95 mg of an aqueous solution of sodium hydroxide (20% by weight) were added and kept stirring for 15 minute. 21 mg of aluminum hydroxide (66% by weight, Sigma-Aldrich) and 607 mg of colloidal silicon dioxide (Ludox AS40, 40% by weight, Aldrich) were then introduced into the synthesis mixture and kept stirring for the required time to evaporate the Solvent until desired gel concentration. The final gel composition is SiO 2 :0.033Al 2 o 3 :0.049Cu(TEPA) 2+ :0.19TMaDA:0.12NaOH:18.3H 2 O.

[0059] The gel was transferred to a Teflon-lined autoclave and heated to a temperature of 150° C. under static conditions...

Embodiment 3

[0062] Example 3: Direct synthesis of "Cu-SSZ13-2" in OH medium

[0063] 325 mg of a 20 wt% aqueous solution of copper(II) sulfate (98 wt%, Alfa) were mixed with 74 mg of tetraethylenepentamine (TEPA, 99 wt%, Aldrich) and kept stirring for 2 hours. Subsequently, 535 mg of aqueous N,N,N-trimethyl-1-adamantane ammonium hydroxide (TMaDA, 16% by weight) and 161 mg of aqueous sodium hydroxide (20% by weight) were added and stirring was maintained for 15 minutes. 21 mg of aluminum hydroxide (66% by weight, Sigma-Aldrich) and 614 mg of colloidal silicon dioxide (Ludox AS40, 40% by weight, Aldrich) were then introduced into the synthesis mixture and kept stirring for the required time to evaporate the solvent to the desired gel concentration. The final gel composition is SiO 2 :0.033Al 2 o 3 :0.10Cu(TEPA) 2+ :0.10TMaDA:0.20NaOH:19.1H 2 O.

[0064] The gel was transferred to a Teflon-lined autoclave and heated to a temperature of 150° C. under static conditions during 14 days. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com