Novel metal-containing zeolite beta for NOx reduction and methods of making the same

A technology containing metal and zeolite, applied in the directions of non-metallic elements, crystalline aluminosilicate zeolite, separation method, etc., can solve the problems of undisclosed zeolite and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

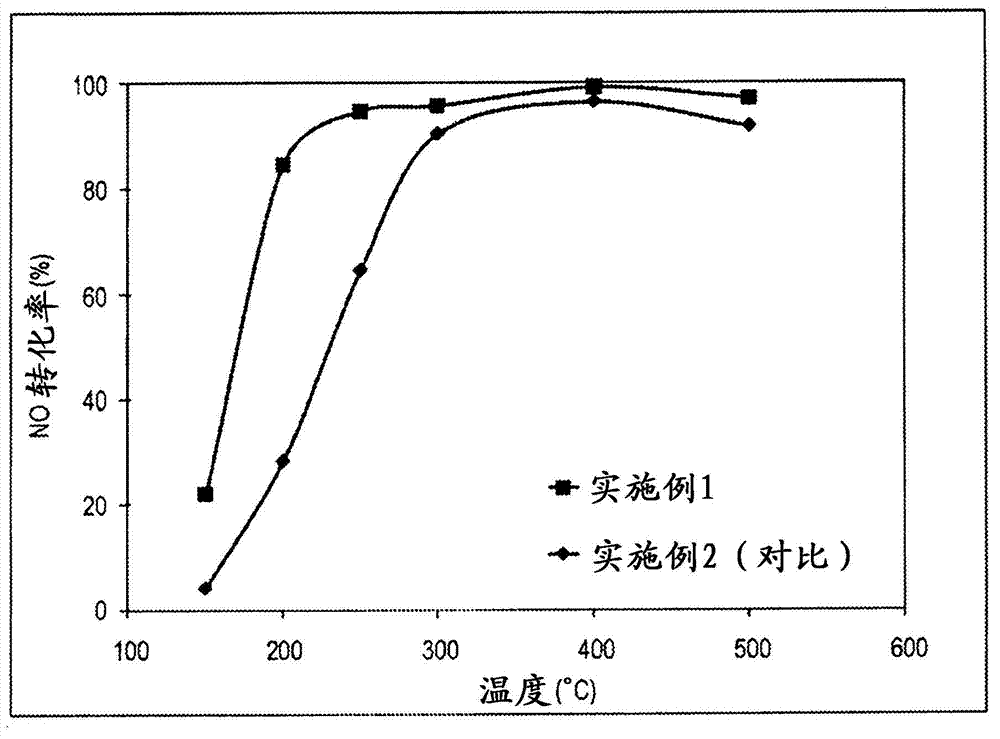

[0055] In addition to the preparation method of the present invention and the zeolite beta of the present invention, methods of using the disclosed zeolite beta of the present invention are also disclosed. For example, a typical diesel engine exhaust contains about 2-15 vol% oxygen and about 20-500 parts per million nitrogen oxides (typically including NO and NO 2 mixture). Nitrogen oxides are reduced with ammonia to form nitrogen and H 2 O can be catalyzed by metal-promoted zeolites, so the process is often referred to as "selective" catalytic reduction ("SCR") of nitrogen oxides.

[0056] Accordingly, a method for selective catalytic reduction of nitrogen oxides in exhaust gas is also disclosed. In one embodiment, the method comprises:

[0057] Exhaust gases are at least partially contacted with an article comprising a metal-containing zeolite beta having a SAR of 5-20, wherein the zeolite beta does not require an organic structure directing agent (SDA) to be prepared and...

Embodiment 1

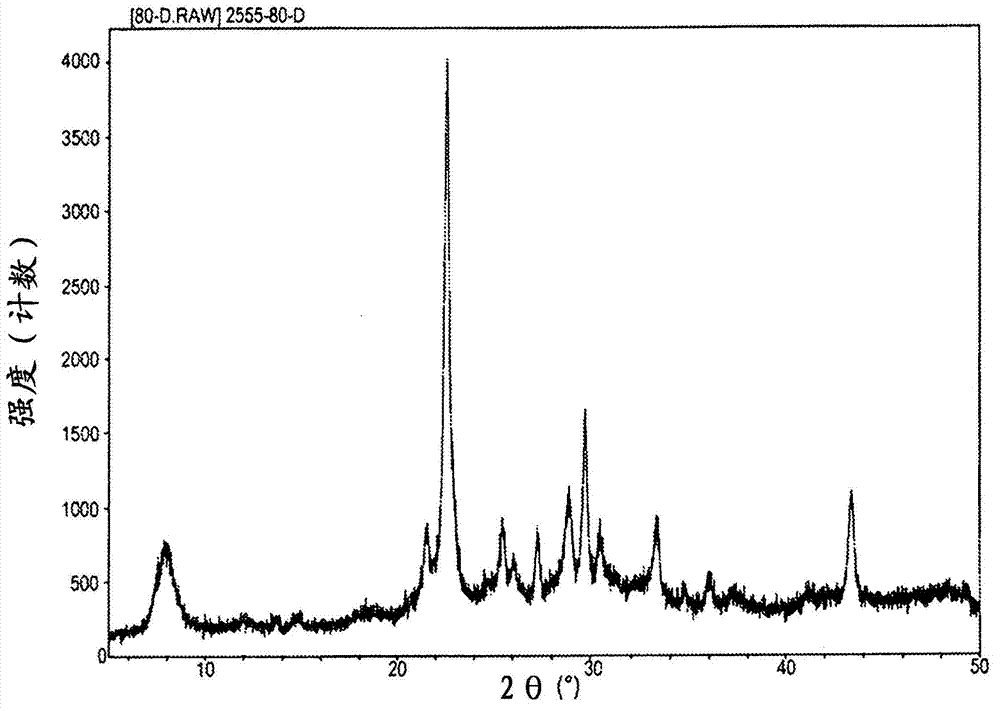

[0068] Example 1: Synthesis of organic-free β (SAR=10.3) and subsequent Fe exchange to produce Fe-β (4.0 wt% Fe, SAR=10.3)

[0069] Water, NaOH (50%) and sodium aluminate (23.5% Al 2 o 3 , 19.6% Na 2 O) mixed together. Silica gel (PQ Corporation) was added to the solution and mixed vigorously for 1 hour. Finally, commercially available zeolite beta (Zeolyst International) was added to the mixture in an amount of 5% by weight relative to the silica content of the slurry and stirred for 30 minutes. The gel has the following molar composition:

[0070]15.0 SiO 2 :1.0Al 2 o 3 :3.8Na 2 O:259H 2 o

[0071] The gel was loaded into 45-mL Parr cartridges and heated to 125°C for 120 hours under static conditions. After cooling, the product is recovered by filtration and washing. The X-ray diffraction pattern of the product shows a pure phase of zeolite beta.

[0072] To remove residual sodium, dissolve the solid in 3.6M NH 4 NO 3 The solution was slurried and stirred at 9...

Embodiment 2

[0075] Example 2. (comparative): Fe-β by aqueous ion exchange (1.0 wt% Fe, SAR=25)

[0076] Commercial zeolite beta (CP814E, SAR=25) from Zeolyst was mixed with FeCl at 80 °C 2 The solution was ion exchanged for 2 hours. After filtering, washing and drying, the Fe-β product has 1.0wt% Fe, 693m 2 / g BET surface area and 0.19cc / g micropore volume.

[0077] After steaming at 700°C for 16h in 10% steam / air, the material has a surface area of 590m 2 / g and the micropore volume is 0.16cc / g.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Crystal size | aaaaa | aaaaa |

| Crystal size | aaaaa | aaaaa |

| Bet surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com