Metal nanoparticle complex and method for producing same

A metal nanoparticle and manufacturing method technology, applied in nanotechnology, nanotechnology, metal processing equipment and other directions, can solve the problems of less ruthenium metal precipitation and larger metal size, and achieve the effect of high activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

manufacture example 1

[0088] Manufacturing example 1: Preparation of PCP complex

[0089] In a 3000ml pear-shaped flask, add 2000ml of DMF-ethanol-water (1:1:1 by volume) and Ni(NO 3 ) 2 ·6H 2 O (23.8g), 2,5-dihydroxyterephthalic acid (H 4 dhtp, 4.8g), stirred and reacted at 100°C for 5 days. The precipitated three-dimensional structure metal complex (Ni 2 (dhtp)) was recovered by suction filtration, and washed with methanol and water. Then, dry under reduced pressure at 25°C for 24 hours to obtain the target metal complex (Ni 2 (dhtp)) 12g. Obtainment of the target metal complex was confirmed by powder X-ray structural analysis. Hereinafter, the obtained metal complex may be referred to as "Ni-MOF-74".

manufacture example 2

[0090] Manufacturing example 2: Preparation of PCP complex

[0091] In a 300ml pear-shaped flask, add 200ml of DMF-ethanol-water (1:1:1 by volume) as a solvent, Co(NO 3 ) 2 ·6H 2 O (2.4g), 2,5-dihydroxyterephthalic acid (H 4 dhtp, 0.5 g), stirred at 100° C. for 5 days, and made to react. The precipitated three-dimensional structure metal complex (Co 2 (dhtp)) was recovered by suction filtration, and washed with methanol and water. Next, drying was performed at 25° C. under reduced pressure for 24 hours to obtain 0.8 g of the target metal complex (Co2(dhtp)). Obtainment of the target metal complex was confirmed by powder X-ray structural analysis.

Embodiment 1

[0093] The Ni complex obtained in Production Example 1 was heated under reduced pressure (under vacuum) using a vacuum pump at the reaction temperature and reaction time shown in Table 2 below to produce the Ni complex of the present invention.

[0094] 【Table 2】

[0095] Synthetic conditions and batch names

[0096]

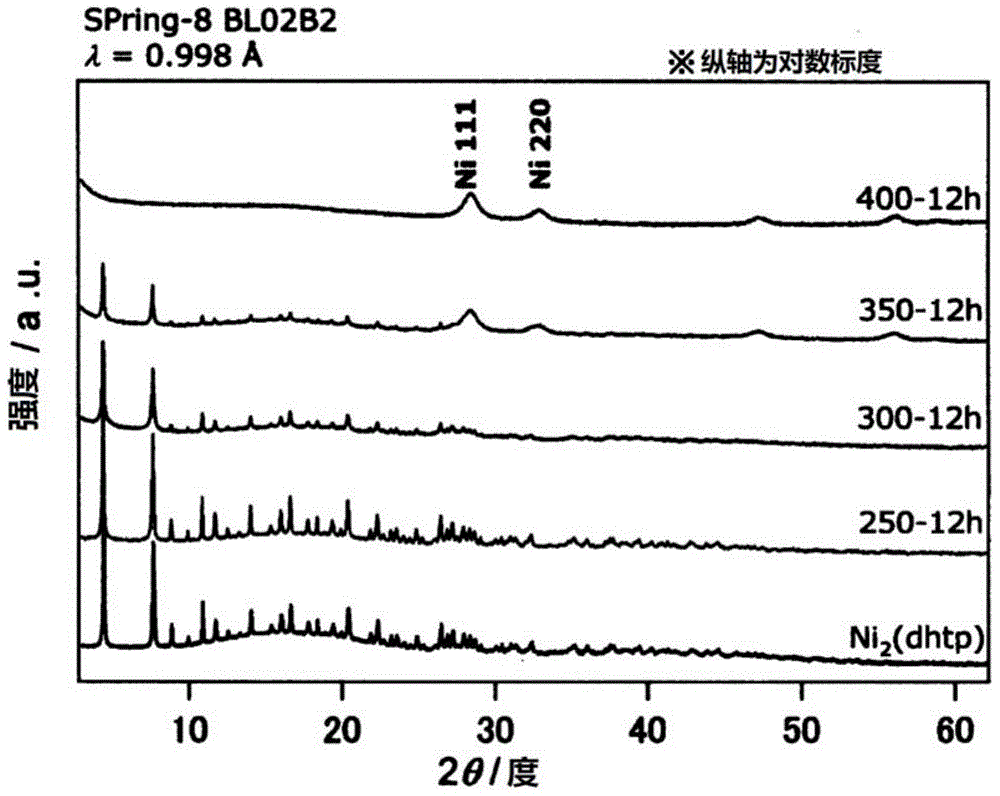

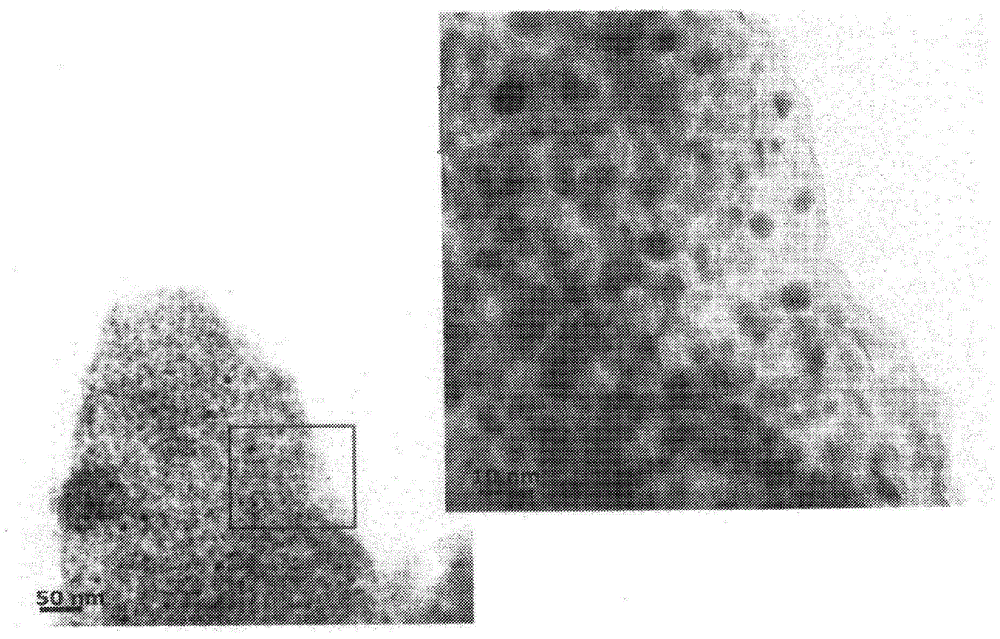

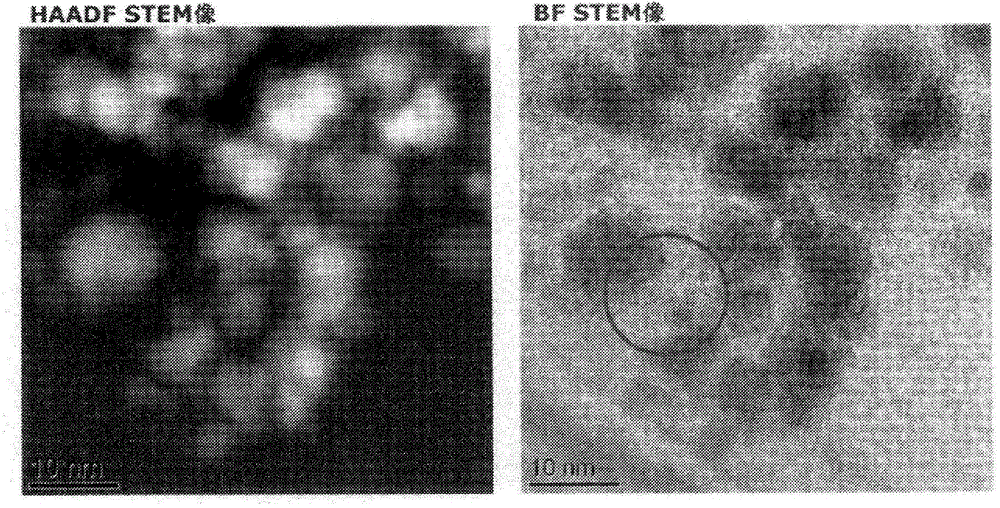

[0097] For the obtained Ni complex, the results of powder X-ray diffraction are shown in figure 1 , the scanning transmission electron microscope (STEM) photograph is shown in figure 2 , the High Resolution Transmission Electron Microscopy (HRTEM) photographs are shown in image 3 , the Raman measurement results are shown in Figure 4 , Figure 5 , the N under 77K 2 The results of the adsorption are shown in Figure 6 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com