A substation anti-noise wall and construction method

A construction method and substation technology, applied to walls, building components, sound insulation, etc., can solve problems such as unfavorable health of people living around, large substation noise control range, and serious substation radiation, so as to avoid electrical damage and reduce construction difficulty , good noise reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

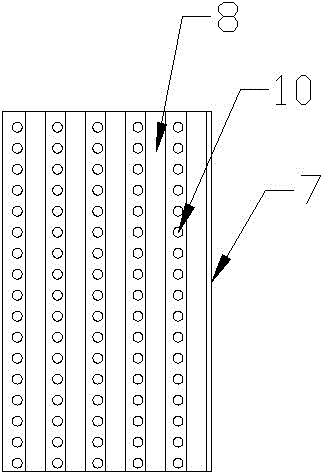

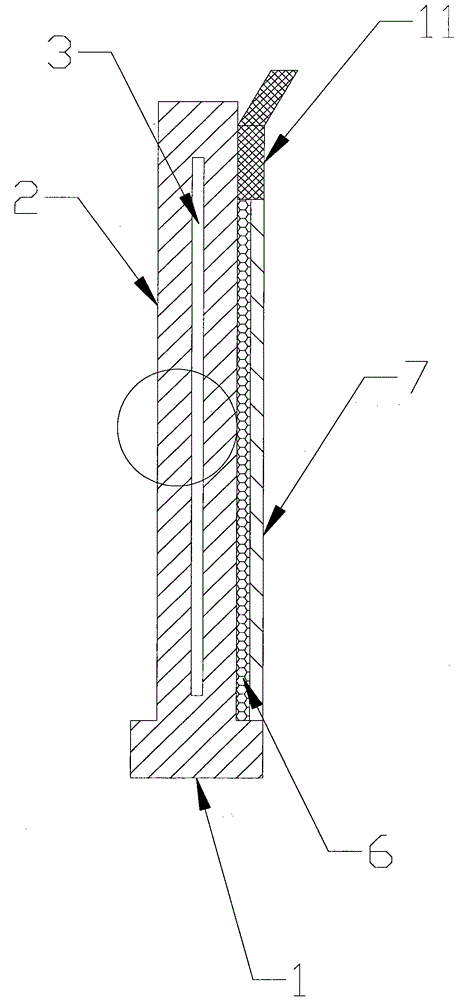

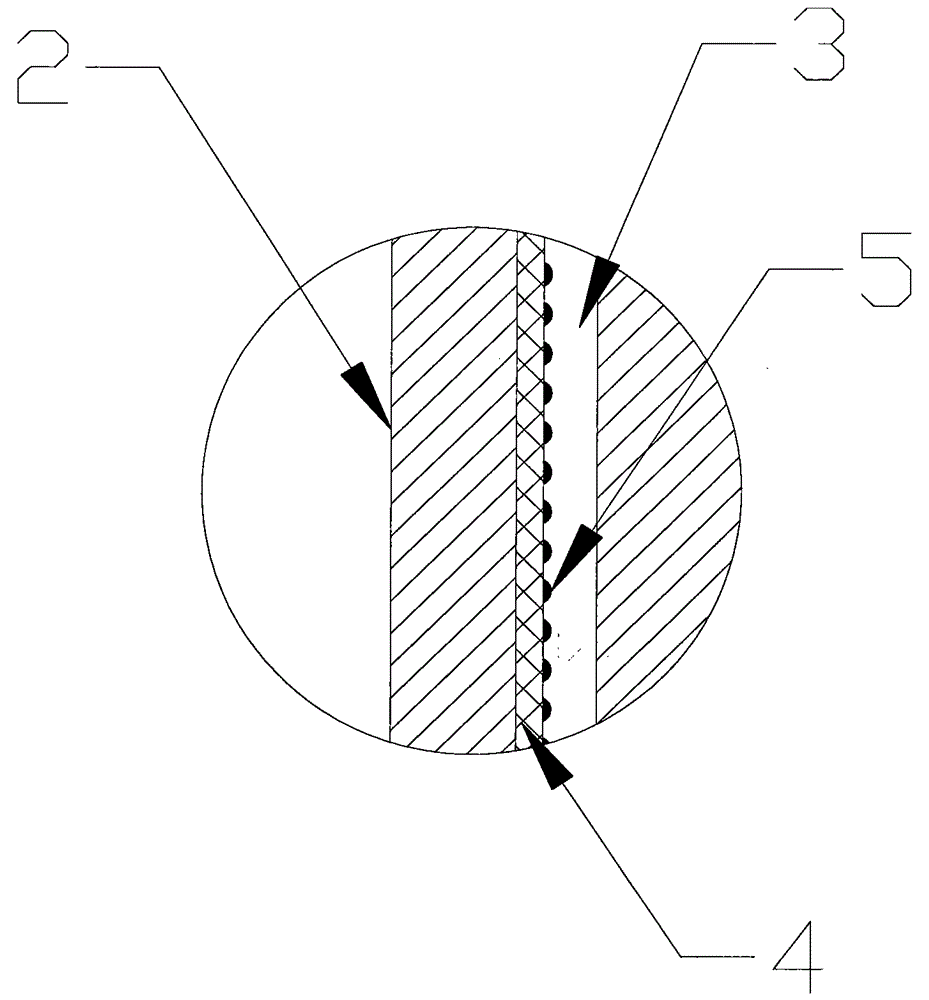

[0032] Such as Figure 1-6 As shown, a substation noise-proof wall, which includes a foundation 1, the upper part of the foundation 1 is provided with a wall 2, the inside of the wall 2 is provided with a cavity A3, the inner cavity of the wall 2 The outside of A3 is provided with a noise insulation board 4, the noise insulation board 4 is riveted with the wall body 2 through rivets, the surface of the noise insulation board 4 is provided with a noise reduction protrusion 5, and the surface of the inner wall of the wall body 2 is provided with There is a radiation protection net 6, the outer surface of the radiation protection net 6 is provided with a noise reduction plate 7, and the upper surface of the noise reduction plate 7 is uniformly and longitudinally provided with a noise reduction strip 8, and the inside of the noise reduction strip 8 is A cavity B9 is provided, and sound-absorbing holes 10 are evenly arranged on the noise-reducing plate 7 between the two noise-reduc...

Embodiment 2

[0042] Such as Figure 1-6 As shown, a substation noise-proof wall, which includes a foundation 1, the upper part of the foundation 1 is provided with a wall 2, the inside of the wall 2 is provided with a cavity A3, the inner cavity of the wall 2 The outside of A3 is provided with a noise insulation board 4, the noise insulation board 4 is riveted with the wall body 2 through rivets, the surface of the noise insulation board 4 is provided with a noise reduction protrusion 5, and the surface of the inner wall of the wall body 2 is provided with There is a radiation protection net 6, the outer surface of the radiation protection net 6 is provided with a noise reduction plate 7, and the upper surface of the noise reduction plate 7 is uniformly and longitudinally provided with a noise reduction strip 8, and the inside of the noise reduction strip 8 is A cavity B9 is provided, and sound-absorbing holes 10 are evenly arranged on the noise-reducing plate 7 between the two noise-reduc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com