Method for preparing ultrafine tungsten carbide powder from arsenic-containing ammonium metatungstate

A technology of ammonium metatungstate and tungsten carbide powder, which is applied in the direction of tungsten/molybdenum carbides and carbides, etc., can solve the problems of difficult mass production, WC particle growth, and difficult process control, etc., to promote development and application, high combined carbon content and low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] A. Add 100.0 g of AMT into 50 ml of nitric acid solution with a mass fraction of 65%~68%, and stir electrically.

[0023] B. After the raw materials are mixed evenly, put them into an oven and dry them at 80°C for 10 hours to prepare the ammonium metatungstate precursor powder.

[0024] C. Put the ammonium metatungstate precursor powder into a box-type resistance furnace, and directly roast it in an air atmosphere at a roasting temperature of 600°C and keep it warm for 2 hours to prepare yellow tungsten trioxide powder.

[0025] D. Put the prepared yellow tungsten trioxide powder into a tubular atmosphere furnace, pass in argon gas to carry out reduction carbonization directly, the heating rate is 5°C / min, the carbonization temperature is 1380~1420°C, and the carbonization time is 1~3h. Prepare tungsten carbide powder.

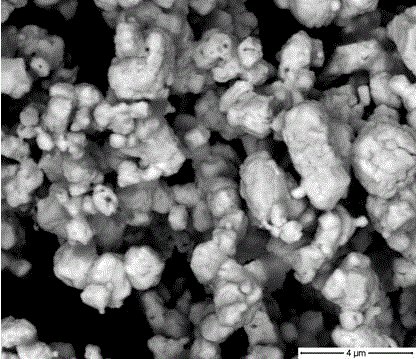

[0026] The tungsten carbide powder prepared by the method described above forms coarse aggregates with poor dispersion and uneven particle size distri...

Embodiment 2

[0028] A. According to the following mass percentage, AMT (ammonium metatungstate) is 99.0wt%, As is 1.0wt%. Dissolve 1.0 g of As in 50 ml of nitric acid with a mass fraction of 65%~68%, and heat in a water bath for 10 h at 30 °C. After As was completely dissolved, 99.0 g of AMT was added into the As nitric acid solution, and the raw materials were fully mixed with electric stirring.

[0029] B. After the raw materials are mixed evenly, put them into an oven and dry them at 80°C for 10 hours to prepare ammonium metatungstate-arsenic precursor composite powder.

[0030] C. Put the ammonium metatungstate-arsenic precursor composite powder into a box-type resistance furnace, and directly roast it in an air atmosphere at a roasting temperature of 600°C for 2 hours to prepare yellow tungsten trioxide powder.

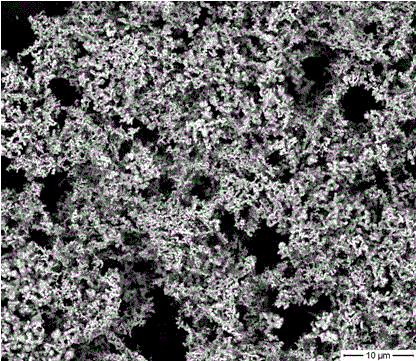

[0031] D. Put the prepared yellow tungsten trioxide powder into a tubular atmosphere furnace, pass in argon gas to carry out reduction carbonization directly, the heating ra...

Embodiment 3

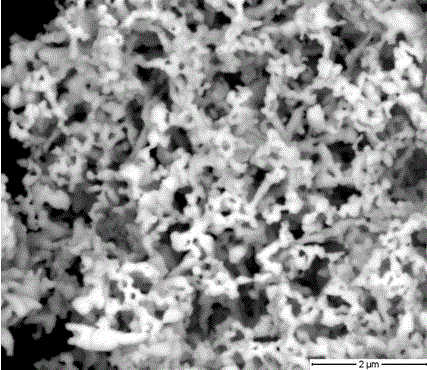

[0034] A. According to the following mass percentage, AMT (ammonium paratungstate) is 99.9wt%, As is 0.1wt%. Dissolve 0.1 g As in 50 ml nitric acid with a mass fraction of 65%~68%, and heat in a water bath for 10 h at 30 °C. After the As was completely dissolved, 99.9 g of AMT was added into the As nitric acid solution, and the raw materials were fully mixed by electric stirring.

[0035] B. After the raw materials are mixed evenly, put them into an oven and dry them at 80°C for 10 hours to prepare ammonium metatungstate-arsenic precursor composite powder.

[0036] C. Put the ammonium metatungstate-arsenic precursor composite powder into a box-type resistance furnace, and directly roast it in an air atmosphere at a roasting temperature of 600°C for 2 hours to prepare yellow tungsten trioxide powder.

[0037] D. Put the prepared yellow tungsten trioxide powder into a tube-type atmosphere furnace, pass in argon gas to carry out reduction carbonization directly, the heating rate...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com