Wood-plastic composite board, preparation method and use thereof

A composite board, wood-plastic technology, applied in the direction of wood layered products, other household appliances, wood veneer joints, etc., can solve the trouble of linking metal skeleton and plastic floor, the weight does not play an obvious advantage, and increase the process. and other problems, to achieve the effect of strong designability, favorable environmental protection and easy cleaning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

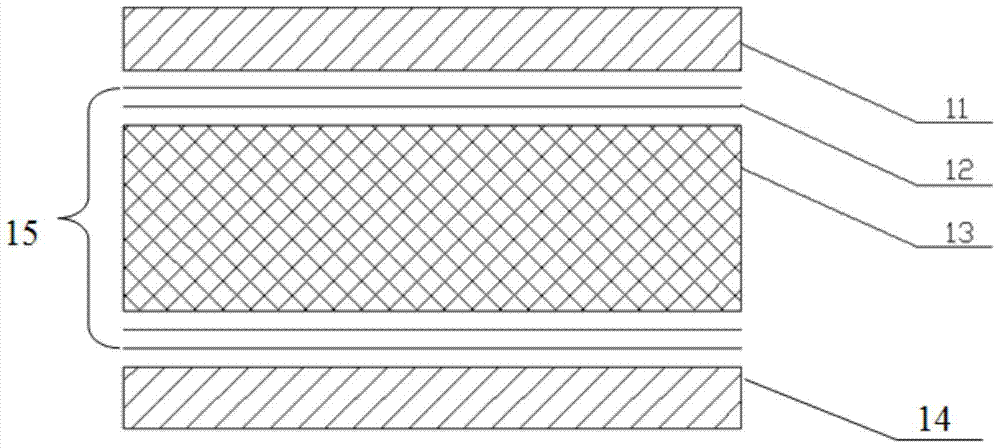

[0050] Such as figure 1 as shown, figure 1 It is a schematic cross-sectional structure diagram of the wood-plastic composite board shown in Example 1, wherein the continuous fiber-reinforced thermoplastic resin board is the surface layer 11 and the bottom layer 14, the reinforcement layer 12 is a glass fiber unidirectional cloth, and the core layer 13 is composed of wood powder and polypropylene The wood-plastic board, the core layer 15 is a wood-plastic board reinforced by glass fiber unidirectional cloth.

[0051] A wood-plastic composite board, the preparation method of which is as follows:

[0052] (1) Both the surface layer 11 and the bottom layer 14 are continuous glass fiber reinforced thermoplastic resin sheets, and the preparation method includes the following steps: spreading the continuous glass fibers and compounding them with extruded and melted resin matrix polypropylene, the fiber mass percentage is 40%, After rolling, the fiber-reinforced thermoplastic prepre...

Embodiment 2

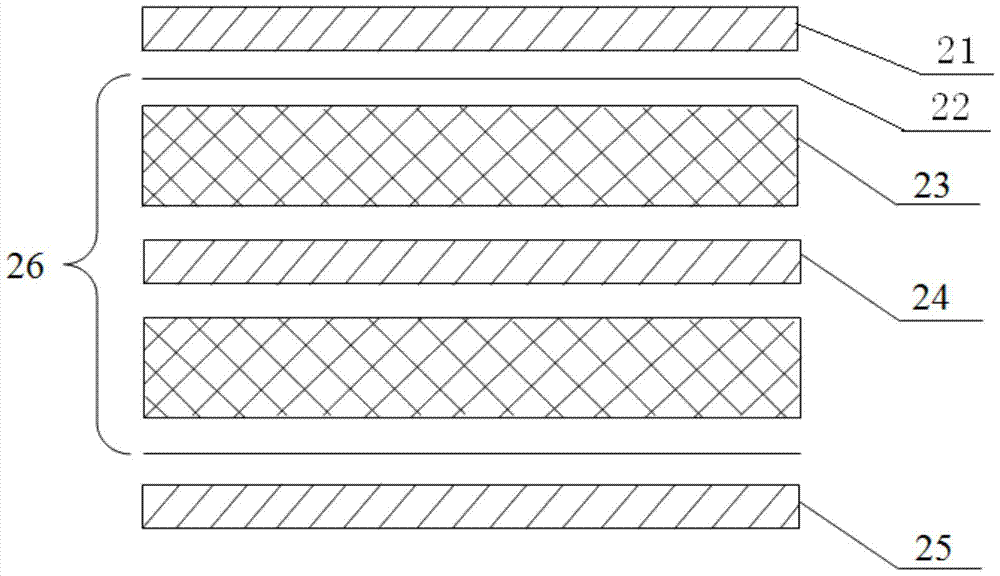

[0058] Such as figure 2 as shown, figure 2 It is a schematic cross-sectional structure diagram of a wood-plastic composite board shown in Example 2, wherein the continuous fiber reinforced thermoplastic resin board is a surface layer 21 and a bottom layer 25, a reinforcement layer 22 is a glass fiber unidirectional cloth, and a core layer 23 is rice husk powder and polystyrene. The wood-plastic board made of ethylene, the reinforcement layer 224 is a long glass fiber reinforced thermoplastic resin board, and the core layer 15.

[0059] A wood-plastic composite board, the preparation method of which is as follows:

[0060] (1) The surface layer 21, the bottom layer 25 and the reinforcement layer 24 are all continuous glass fiber reinforced thermoplastic resin sheets. The preparation method includes the following steps: unfolding the continuous glass fiber and compounding it with the extruded molten resin matrix polyethylene, the fiber mass percentage After rolling, the fibe...

Embodiment 3

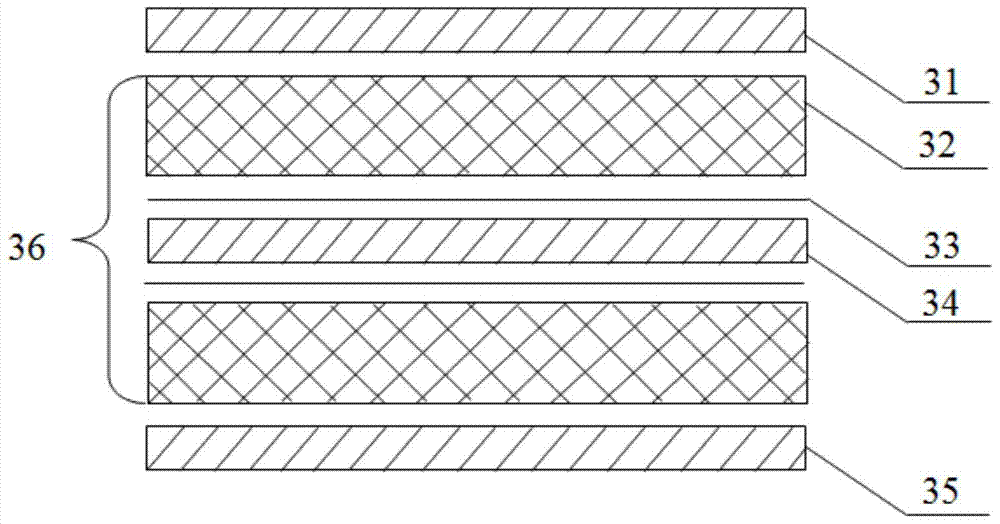

[0066] Such as image 3 as shown, image 3 It is a schematic cross-sectional structure diagram of the wood-plastic composite board shown in Example 3, wherein the continuous fiber-reinforced thermoplastic resin board is the surface layer 31 and the bottom layer 35, the core layer 32 is a wood-plastic board prepared by straw powder and polyvinyl chloride, and the reinforcement layer one 33 glass fiber unidirectional cloth, reinforcement layer 2 34 is long glass fiber reinforced thermoplastic resin plate, core layer 15.

[0067] A wood-plastic composite board, the preparation method of which is as follows:

[0068] (1) The surface layer 31, the bottom layer 35 and the reinforcing layer 2 34 are all continuous glass fiber reinforced thermoplastic resin sheets, and the preparation method includes the following steps: spreading the continuous glass fibers, compounding them with the extruded molten resin matrix polyvinyl chloride, and the fibers The mass percentage is 50%, and aft...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com