A kind of equal-volume reciprocating extrusion device and processing method of reinforced magnesium alloy plate

A reciprocating extrusion and magnesium alloy technology, applied in the direction of metal extrusion dies, etc., can solve the problems of not meeting the market demand for high-strength magnesium alloy sheets, the inability to produce reinforced magnesium alloy sheets, and the limitations of wide application, etc., to achieve good extrusion processing Effect, large-scale application prospect, simple mold structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] The present invention will be further described below in conjunction with accompanying drawing and specific embodiment:

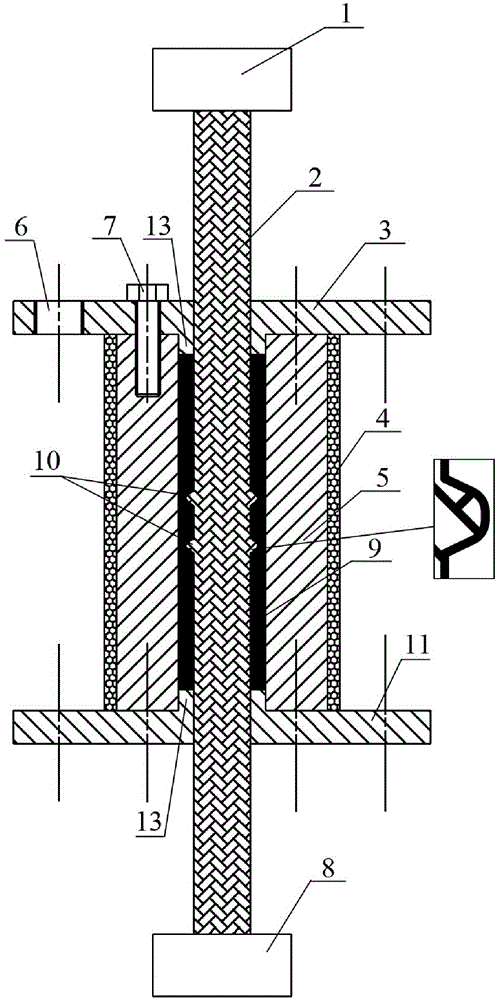

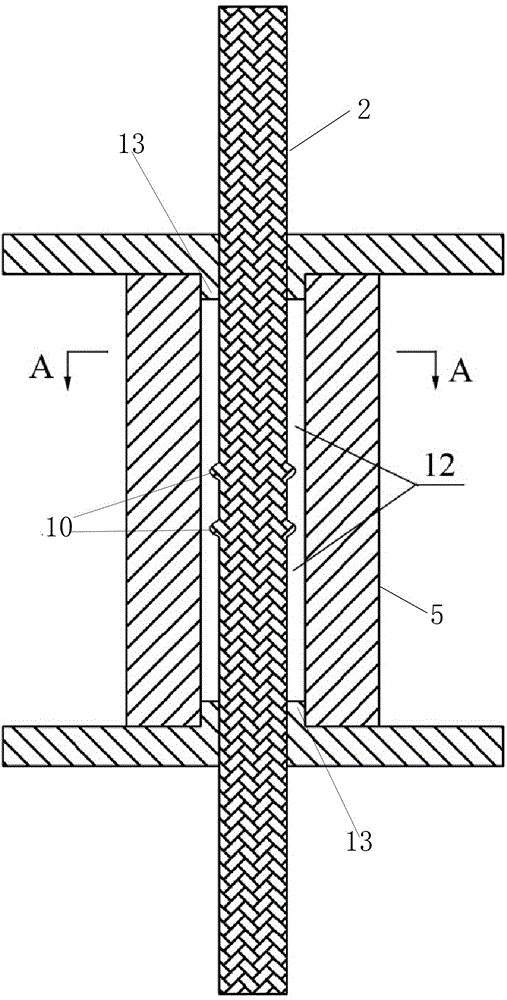

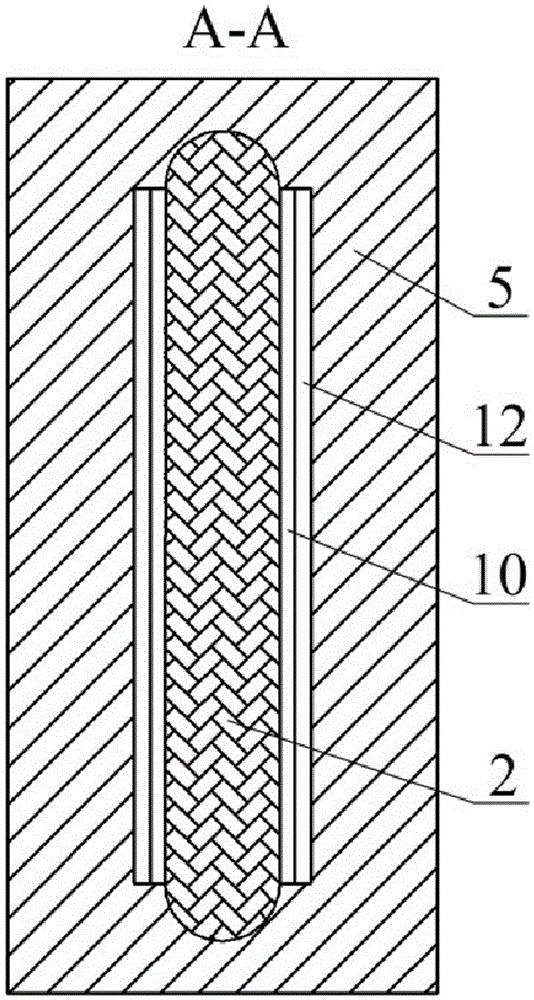

[0043] Such as figure 1As shown, the equal-volume reciprocating extrusion device for preparing reinforced magnesium alloy plates includes: 1. Upper extrusion telescopic head, 2. Extrusion punch, 3. Upper fixed platen, 4. Heating jacket, 5. Extrusion Die, 6. Fixing screw holes, 7. Fixing bolts, 8. Lower extruding telescopic head, 9. Magnesium alloy plate blank, 10. Raised area, 11. Lower fixing platen. Among them, the upper and lower extrusion telescopic heads are respectively connected with the upper and lower ends of the extrusion punch 2, the surface roughness of the extrusion punch 2 is Ra0.08-0.16 μm, and the two sides of the extrusion punch 2 (that is, facing Both sides of the extrusion channel) are provided with two raised areas 10 in the middle, and the longitudinal section of the raised areas 10 is trapezoidal ( figure 1 The enlarged pictur...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface roughness | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com