Electric response infrared reflection window and infrared reflection method

A technology of infrared reflection and electrical response, applied in optics, nonlinear optics, static indicators, etc., can solve the problem that reflective materials are easy to interfere with navigation and communication systems, coated glass windows are difficult to use in a large number of buildings, unfavorable for the popularization of coated glass windows and Wide application and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

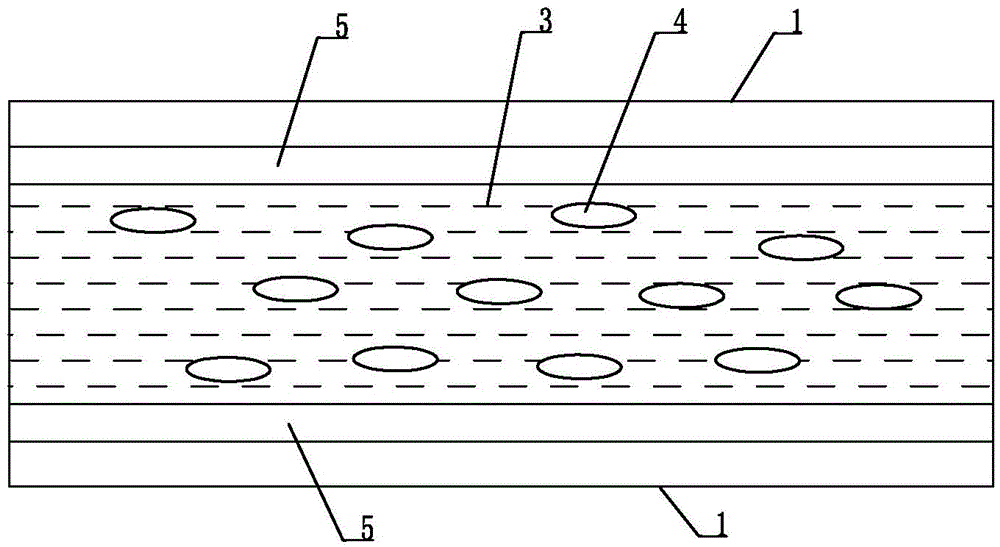

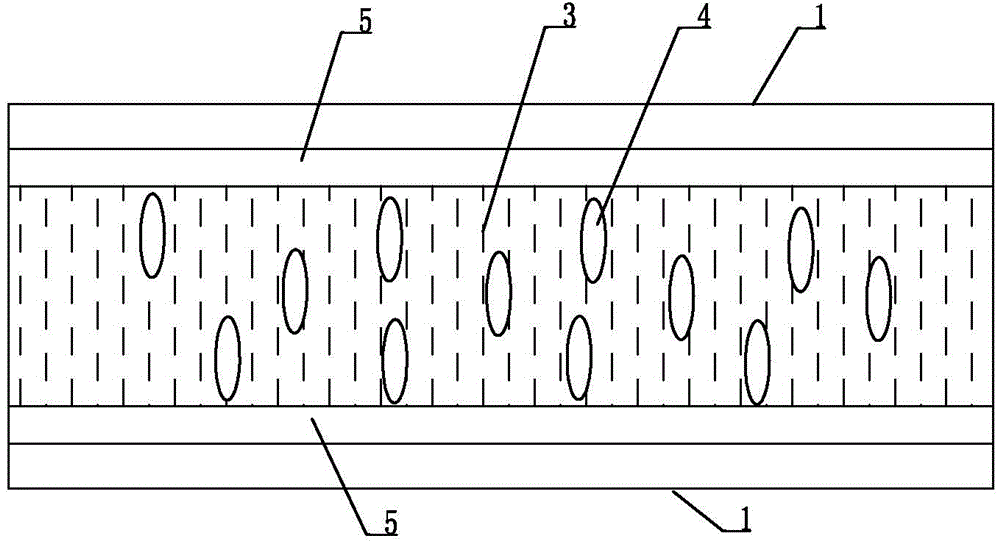

[0072] The preparation of liquid crystal film can adopt following steps to realize:

[0073] 1) Configure mixed liquid crystals: under yellow light conditions, weigh nematic liquid crystals A, nematic liquid crystals B, nematic liquid crystals C, chiral liquid crystals and photoinitiators into UV-resistant reagent bottles in proportion, then press Prepare the polymerization inhibitor according to the ratio, and configure it as a polymerization inhibitor solution with a concentration of 100-300ppm; then add the polymerization inhibitor solution into the anti-ultraviolet reagent bottle and mix evenly, and dry the mixed solution naturally until the solvent is completely volatilized to obtain The liquid crystal is mixed; the solvent used for the polymerization inhibitor solution can be easily volatile as long as it is compatible with each component and does not react with each component; for example, tetrahydrofuran can be used as a solvent.

[0074] 2) Filling and orientation of ...

Embodiment 1

[0092] Liquid crystal cell preparation

[0093] a) Clean the glass substrates 7 and 8 .

[0094] Use acetone, deionized water, and isopropanol to clean in an ultrasonic cleaner for 10 minutes in sequence; finally, dry in an oven at 120°C for 30 minutes.

[0095] b) Preparation of polyimide alignment layer.

[0096] Use N-methylpyrrolidone (NMP) and ethylene glycol butyl ether (BCS) to dilute the DL-2590 polyimide solution at a ratio of 4:1 to a solid content of 2%. Then spin-coat the diluted polyimide solution onto the glass substrates 7 and 8 of 30mm*30mm, the spin-coating speed is 2500r / min, and the time is 1min, thereby forming a layer of polyimide on the glass substrates 7 and 8. Amine film; then pre-baking and curing the glass plates 7 and 8, the pre-baking temperature is 90°C, and the baking time is 90s; the curing is divided into two steps: first set the oven temperature to 105°C, and bake for 30min , then raise the temperature to 250°C and keep the temperature const...

Embodiment 2

[0105] Preparation of liquid crystal cell: same as Example 1.

[0106] Preparation of liquid crystal thin films

[0107] 1) Configure mixed liquid crystals: under yellow light conditions, mix nematic liquid crystals A, nematic liquid crystals B, nematic liquid crystals C, chiral liquid crystals and photoinitiators according to HCM-008: HCM-021: HCM-020: HCM-006: Photoinitiator-2959=25:35:37.09:1.9:1 ratio, weighed into a brown reagent bottle; then weigh an appropriate amount of p-benzoquinone inhibitor in proportion, and configure it to a concentration of 100ppm of benzoquinone polymerization inhibitor solution was added to the reagent bottle and mixed evenly; then the mixed solution was naturally dried until the solvent was completely volatilized to obtain a mixed liquid crystal;

[0108] 2) Filling and orientation of liquid crystals: under yellow light, heat the mixed liquid crystals to 90°C to transform each liquid crystal into an isotropic liquid state, then inject the mi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com