Low-carbon silicon-manganese high-strength steel containing Cu and production method of steel

A carbon-silicon-manganese-based technology and a production method, which are applied in the metallurgical field, can solve the problems of reducing the strength of lath martensite, the carbon content cannot be too low, and the carbon distribution effect is limited, so as to improve strength and toughness, improve mechanical properties, and improve production Simple and easy method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

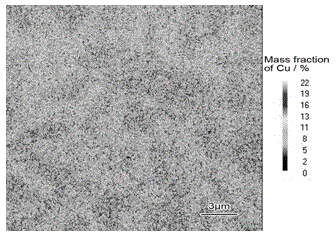

[0026] A Cu-containing low-carbon silicon-manganese high-strength steel, the chemical composition mass percentage is: C: 0.18%, Si: 1.5%, Mn: 1.3%, Cu: 0.55%, Ni: 0.4%, P: 0.04%, S: 0.02%, the balance is Fe and unavoidable impurities. The elongation of Cu-containing low-carbon silicon-manganese high-strength steel is 25%, the strength-plastic product is 31180MPa·%, and the retained austenite content is 10.2%.

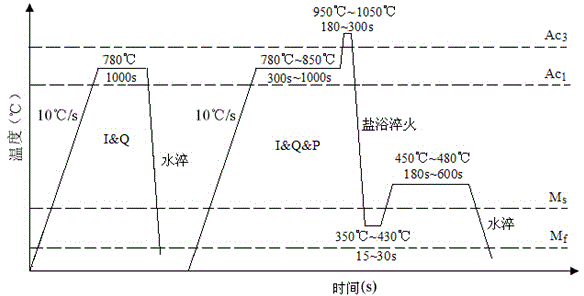

[0027] A production method of Cu-containing low-carbon silicomanganese high-strength steel is carried out as follows:

[0028] (1) Smelting is carried out according to the above chemical composition, and the cast billet is forged into a slab;

[0029] (2) Hot rolling the slab to obtain a final rolled plate;

[0030] Hot rolling is divided into rough rolling and finish rolling in sequence; the rough rolling start temperature is 1080°C, the rough rolling pass deformation is 35%, the finish rolling total deformation is 55%, the final rolling temperature is 840°C, and the...

Embodiment 2

[0033] A Cu-containing low-carbon silicon-manganese high-strength steel, the chemical composition mass percentage is: C: 0.22%, Si: 1.3%, Mn: 1.5%, Cu: 0.4%, Ni: 0.34%, P: 0.02%, S: 0.01%, the balance is Fe and unavoidable impurities. The elongation of Cu-containing low-carbon silicon-manganese high-strength steel is 22.3%, the strength-plastic product is 30240MPa·%, and the retained austenite content is 9.6%.

[0034] A production method of Cu-containing low-carbon silicomanganese high-strength steel is carried out as follows:

[0035] (1) Smelting is carried out according to the above chemical composition, and the cast billet is forged into a slab;

[0036] (2) Hot rolling the slab to obtain a final rolled plate;

[0037] Hot rolling is divided into rough rolling and finish rolling in sequence; the rough rolling start temperature is 1050°C, the rough rolling pass deformation is 45%, the finish rolling total deformation is 60%, the final rolling temperature is 850°C, and th...

Embodiment 3

[0040]A Cu-containing low-carbon silicon-manganese high-strength steel, the chemical composition mass percentage is: C: 0.2%, Si: 1.5%, Mn: 1.8%, Cu: 0.5%, Ni: 0.32%, P: 0.05%, S: 0.03%, the balance is Fe and unavoidable impurities. The elongation of Cu-containing low-carbon silicon-manganese high-strength steel is 20.8%, the strength-plastic product is 28589MPa·%, and the retained austenite content is 8.5%.

[0041] A production method of Cu-containing low-carbon silicomanganese high-strength steel is carried out as follows:

[0042] (1) Smelting is carried out according to the above chemical composition, and the cast billet is forged into a slab;

[0043] (2) Hot rolling the slab to obtain a final rolled plate;

[0044] Hot rolling is divided into rough rolling and finish rolling in sequence; the rough rolling start temperature is 1030°C, the rough rolling pass deformation is 25%, the finish rolling total deformation is 50%, the final rolling temperature is 830°C, and the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| strength | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com