A connection device for fermentation container and extracellular fermentation product research container

The technology of a fermentation container and a connecting device is applied in the field of connecting devices of fermentation and product research systems, and achieves the effects of simple and fast assembly and convenient application.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

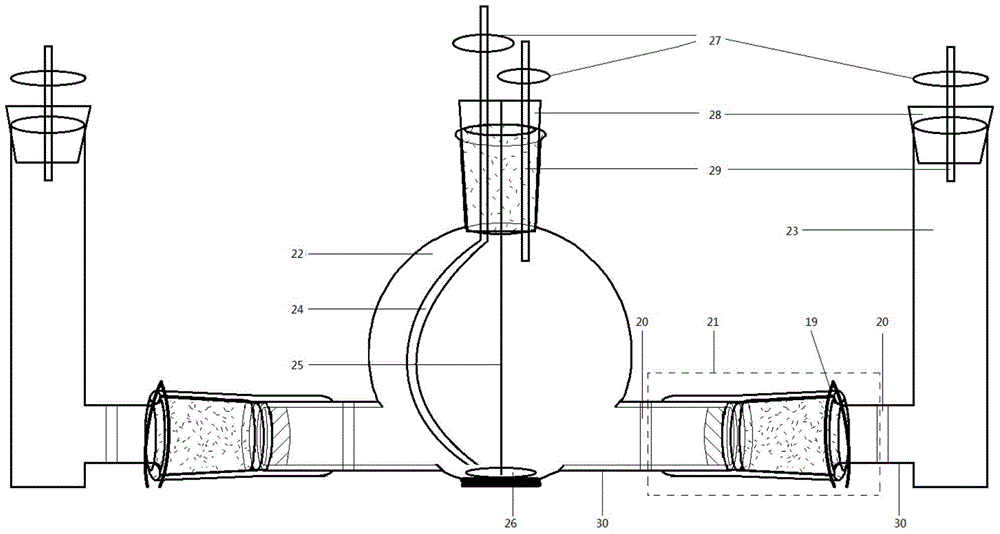

[0023] Press the regenerated cellulose membrane (10) with a molecular weight of 5KDa that can be cut off on the top section (8) of the G1 sand chip (6), and then press the "O" type silica gel gasket (11), insert the tube (16) Insert into the glass sleeve (1), and the bottom section (12) of the insertion tube tightly squeezes the "O"-shaped silicone gasket placed in the glass sleeve to make the "O"-shaped silicone gasket (11), the regenerated cellulose diaphragm ( 10) It is tightly connected with the G1 sand chip (6). During the assembly process, the insertion tube (16) and the glass sleeve (1) are tightly connected through the frosting inside the outer tube of the glass sleeve (14) and the frosting outside the insertion tube (15). clamp (19) at the clamping interface (such as figure 2 shown), so that figure 1 Shown connecting device (21) is tightly connected, promptly obtains the connecting device (such as figure 1 shown).

Embodiment 2

[0025] Press the regenerated cellulose membrane (10) with a cut-off molecular weight of 1KDa on the top section (8) of the G1 sand chip (6), and then press the "O" type silica gel gasket (11), insert the insertion tube (16) Insert into the glass sleeve (1), the bottom section (12) of the insertion tube tightly squeezes the "O" type silicone gasket placed in the glass sleeve to make the "O" type silicone gasket (11), and the regenerated cellulose diaphragm ( 10) It is tightly connected with the G1 sand chip (6). During the assembly process, the insertion tube (16) and the glass sleeve (1) are tightly connected through the frosting inside the outer tube of the glass sleeve (14) and the frosting outside the insertion tube (15). Clamp (19) to clamp figure 2 interface shown so that figure 1 The connecting device (21) shown is tightly connected.

[0026] then figure 1 The shown connecting device (21) is connected at the screw connection (20) by the thread (18) at the two ends of...

Embodiment 3

[0037] Press regenerated cellulose membranes (10) with cut-off molecular weights of 1KDa and 5KDa on the top section (8) of the G1 sand chip (6) of the two sets of glass sleeves (1), respectively, and then press two " O"-shaped silicone gasket (11), insert the two insertion tubes (16) into the two glass sleeves (1) respectively, and the bottom section of the insertion tube (12) tightly squeezes the "O" placed in the glass sleeve Type silicone gasket, so that the "O" type silicone gasket (11), regenerated cellulose diaphragm (10) and G1 sand chip (6) are tightly connected, and the insertion tube (16) and the glass casing (1) pass through the outside of the glass casing The frosting inside the tube (14) is closely connected with the frosting outside the insertion tube (15), and the two grinding mouth clamps (19) are clamped respectively as image 3 The shown interface makes the two sets of connecting devices (21) tightly connected.

[0038] two more sets figure 1 The shown con...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com