LiZn ferrite material with low coercive force

A ferrite material and low coercivity technology, applied in the field of ferrite materials, can solve the problems affecting the performance of microwave phase shifters, the consistency of amplitude and phase, the yield, the material utilization rate and processability are not ideal, the Li system The problem of high ferrite loss can achieve the effect of optimizing particle size and particle size distribution, small porosity, and short reaction time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

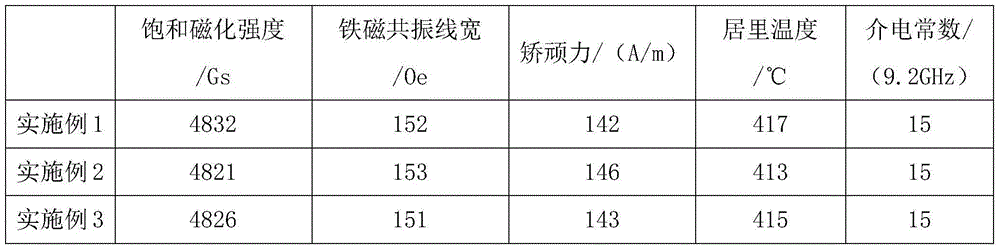

Examples

Embodiment 1

[0018] A low-coercivity LiZn ferrite material, weigh the raw materials according to the following ratio:

[0019] Fe 2 O 3 , ZnO, Li 2 CO 3 , Bi 2 O 3 , Mn 3 O 4 , Nb 2 O 5 , Polyvinyl alcohol, of which Fe 2 O 3 : ZnO: Li 2 CO 3 The molar ratio is 48:13:7, with Fe 2 O 3 , ZnO, Li 2 CO 3 The quality of the three is the benchmark, Bi 2 O 3 , Mn 3 O 4 , Nb 2 O 5 The mass fractions are 1.8%, 1.7%, 0.21%, respectively, with Fe 2 O 3 , ZnO, Li 2 CO 3 , Bi 2 O 3 , Mn 3 O 4 , Nb 2 O 5 Based on the sum of the six masses, the mass fraction of polyvinyl alcohol is 16%;

[0020] According to the above-mentioned ingredients, the low coercivity LiZn ferrite material is prepared according to the following steps:

[0021] S1: One ball milling: Fe 2 O 3 , ZnO, Li 2 CO 3 Put it into the ball mill and use the speed of 192r / min to perform mixed ball milling. After ball milling for 2 hours, it is dried and ready for use. The mass ratio of powder: water: ball is 1:1.2:3;

[0022] S2: Pre-burning: Put the po...

Embodiment 2

[0026] A low-coercivity LiZn ferrite material, weigh the raw materials according to the following ratio:

[0027] Fe 2 O 3 , ZnO, Li 2 CO 3 , Bi 2 O 3 , Mn 3 O 4 , Nb 2 O 5 , Polyvinyl alcohol, of which Fe 2 O 3 : ZnO: Li 2 CO 3 The molar ratio is 45:13:6, with Fe 2 O 3 , ZnO, Li 2 CO 3 The quality of the three is the benchmark, Bi 2 O 3 , Mn 3 O 4 , Nb 2 O 5 The mass fractions are 1.5%, 2%, 0.25%, respectively, with Fe 2 O 3 , ZnO, Li 2 CO 3 , Bi 2 O 3 , Mn 3 O 4 , Nb 2 O 5 Based on the sum of the six masses, the mass fraction of polyvinyl alcohol is 17%;

[0028] According to the above-mentioned ingredients, the low coercivity LiZn ferrite material is prepared according to the following steps:

[0029] S1: One ball milling: Fe 2 O 3 , ZnO, Li 2 CO 3 Put it into the ball mill and use the speed of 198r / min to perform mixed ball milling. After the ball milling for 1.5 hours, it is dried and ready for use. The mass ratio of powder: water: ball is 1:1.3:3.2;

[0030] S2: Pre-burning: Put ...

Embodiment 3

[0034] A low-coercivity LiZn ferrite material. Weigh the raw materials according to the following ratio:

[0035] Fe 2 O 3 , ZnO, Li 2 CO 3 , Bi 2 O 3 , Mn 3 O 4 , Nb 2 O 5 , Polyvinyl alcohol, of which Fe 2 O 3 : ZnO: Li 2 CO 3 The molar ratio is 47:11:8, with Fe 2 O 3 , ZnO, Li 2 CO 3 The quality of the three is the benchmark, Bi 2 O 3 , Mn 3 O 4 , Nb 2 O 5 The mass fractions are 2.2%, 1.5%, 0.15%, respectively, with Fe 2 O 3 , ZnO, Li 2 CO 3 , Bi 2 O 3 , Mn 3 O 4 , Nb 2 O 5 Based on the sum of the six masses, the mass fraction of polyvinyl alcohol is 14%;

[0036] According to the above-mentioned ingredients, the low coercivity LiZn ferrite material is prepared according to the following steps:

[0037] S1: One ball milling: Fe 2 O 3 , ZnO, Li 2 CO 3 Put it into a ball mill and use a speed of 190r / min to perform mixed ball milling. After ball milling for 2.5 hours, it will be dried and ready for use. The mass ratio of powder: water: ball is 1:1.1:2.8;

[0038] S2: Pre-burning: Put t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com