Method and device for treating sewage and producing biogas

A sewage treatment method and sewage treatment technology, applied in the direction of water/sewage multi-stage treatment, water/sludge/sewage treatment, sludge treatment, etc., can solve the problem of large excess sludge production, low anaerobic decomposition rate, and blower consumption and other problems, to achieve the effect of less excess sludge generation, high treatment efficiency, and reduced energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

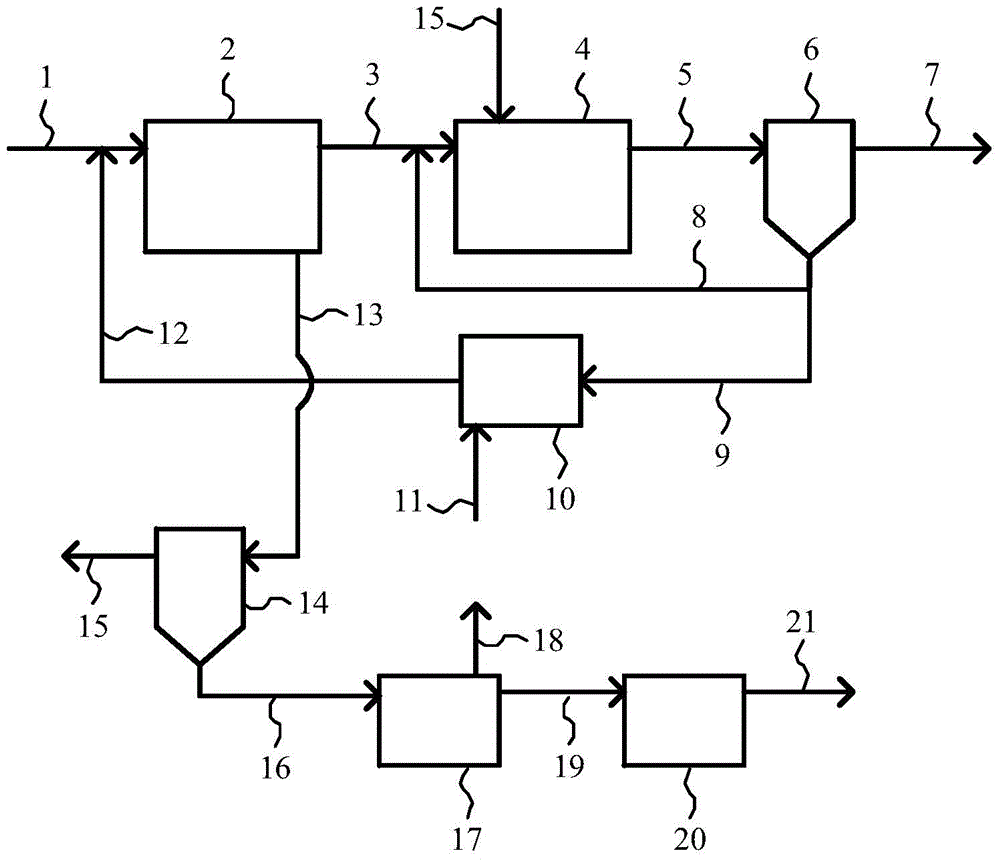

[0025] The treatment object of this embodiment is urban domestic sewage containing suspended and colloidal organic matter. Sewage is pretreated by grilles, grit chambers, primary sedimentation tanks, etc. to remove inorganic impurities and then enters such as figure 1 Processing system shown.

[0026]After including the biological treatment system treatment 9 of aerobic treatment, the aerobic residual sludge 9 obtained in the effluent sedimentation tank 6 after the anaerobic-aerobic-anoxic-aerobic treatment passes through the sludge aeration conditioning tank 10 ( After air 11) conditioning, the regenerated sludge 12 flows to the adsorption sedimentation tank 2, and is fully mixed with the incoming treated sewage raw water 1. Through the physical adsorption and biological adsorption of activated sludge, it is quickly adsorbed and suspended in the sewage. and organic matter in a colloidal state; after the adsorption is sufficient, the adsorption sludge 13 and the supernatant 3...

Embodiment 2

[0028] The treatment object of this embodiment is the city sewage that contains the suspended state of lower concentration, colloidal state organic matter, and flow process is basically the same as embodiment 1, and difference is that the settling tank 6 volume of design is larger, and the mud-water mixture after sewage biological treatment 5 The residence time in the sedimentation tank 6 is longer, and the implementation process is omitted figure 1 The aeration regulating tank 10 in.

[0029] The specific process is as follows: the sewage enters the system of the present invention after being pretreated by grilles, grit chambers, primary sedimentation ponds, etc. to remove inorganic impurities. Sewage raw water 1 flows into adsorption settling tank 2. At the same time, aerobic excess sludge 9 is directly sent from settling tank 6 to adsorption settling tank 2. After mixing and settling with incoming sewage raw water 1, the supernatant enters sewage biological treatment purifi...

Embodiment 3

[0031] The treatment object of this embodiment is the industrial sewage containing higher concentration of suspended state and colloidal organic matter. The mud-water mixture stays in the adsorption sedimentation tank 2 for a long time, and the implementation process is omitted figure 1 The sludge thickening tank 14 in. The sludge 13 adsorbed with a large amount of organic matter separated from the adsorption settling tank 2 directly enters the anaerobic fermentation biogas production device 17 for anaerobic fermentation. In the aeration conditioning tank 10, the dissolved oxygen in the sludge is controlled between 4 mg / l, and the aeration is performed for 15 minutes. Through the treatment of the system of this embodiment, compared with the traditional process, the aeration power consumption of aerobic treatment is saved by 55%, the residence time of biogas fermentation is shortened by 6 days, the amount of biogas produced is increased by 40%, and the amount of sludge produce...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com