An advanced oxidation coupling device and process for the treatment of refractory organic wastewater

A technology for organic wastewater treatment and advanced oxidation, applied in water/sewage treatment, oxidized water/sewage treatment, water/sewage treatment equipment, etc., can solve low current efficiency, lack of flexibility, poor mass transfer effect of reactors, etc. problems, to achieve the effect of saving operating costs and improving removal efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

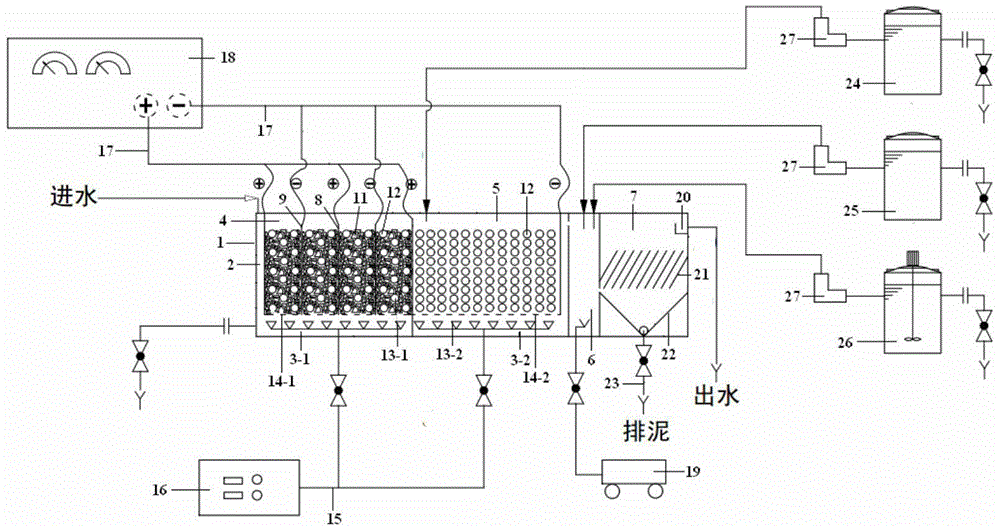

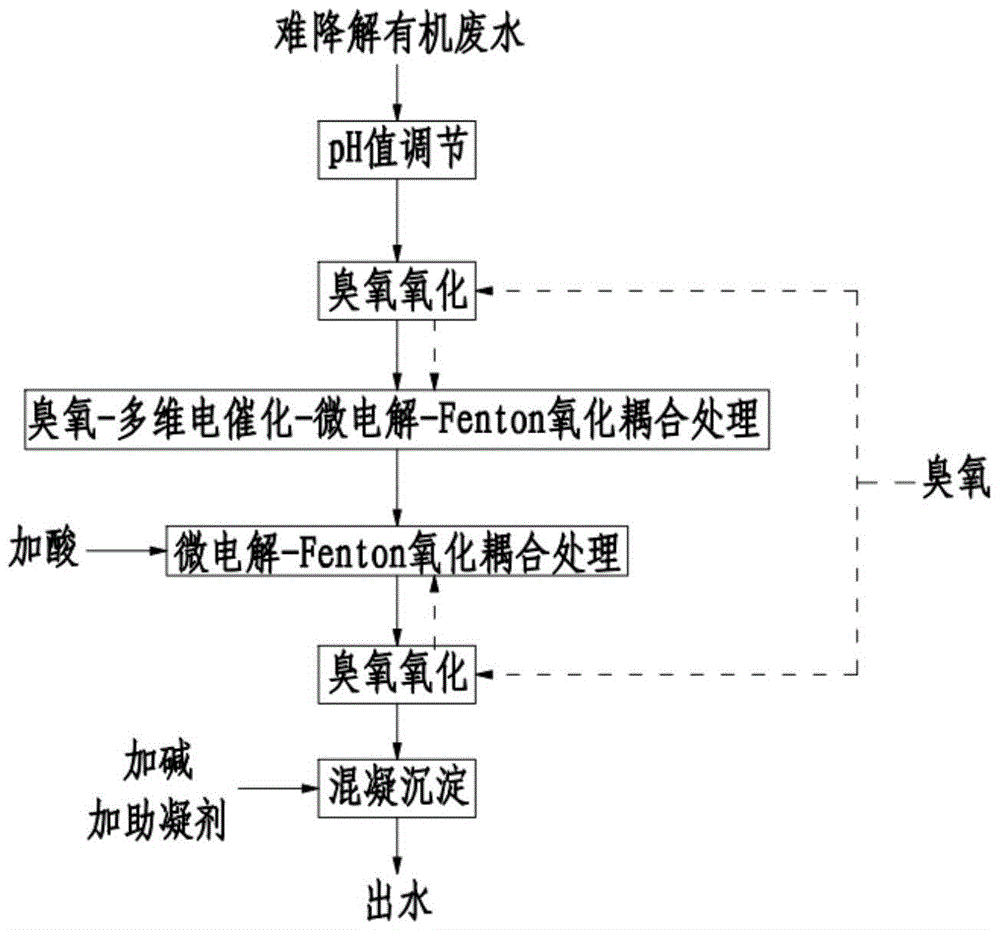

[0076] Production wastewater of a pharmaceutical company, raw water COD 28200mg / L, pH value 8.5, B / C 0.11. Using an advanced oxidation coupling device and process treatment for refractory organic wastewater treatment of the present invention, the pH of the raw water is adjusted to 8.0; it enters the first ozone oxidation zone for treatment, the input amount of ozone is 8g / h, and the residence time of wastewater is 30min; Then enter the multi-dimensional electrocatalysis / micro-electrolysis area for treatment, the anode plate is coated with IrO 2 titanium plate, the cathode plate adopts a graphite plate with a purity of 99.9%, the distance between the anode plate and the cathode plate is 10cm, and the current density is controlled at 10mA / cm 2 , electrocatalytic particles and micro-electrolysis particles are mixed at a ratio of 3:1, and the residence time of the wastewater is 120min; then it enters the micro-electrolysis / Fenton zone for treatment, adding acid to adjust the pH va...

Embodiment 2

[0078] The production wastewater of a reactive dyestuff enterprise, the raw water COD 1360mg / L, pH value 9.6, B / C 0.21. Adopt an advanced oxidation coupling device and process treatment for refractory organic wastewater treatment of the present invention, adjust the pH of the raw water to 7.5; enter the first ozone oxidation zone for treatment, the input amount of ozone is 6g / h, and the residence time of wastewater is 10min; Then enter the multi-dimensional electrocatalysis / micro-electrolysis area for treatment, the anode plate is coated with TiO 2 titanium plate, the cathode plate adopts a graphite plate with a purity of 99.9%, the distance between the anode plate and the cathode plate is 20cm, and the current density is controlled at 20mA / cm 2 , electrocatalytic particles and micro-electrolysis particles are mixed at a ratio of 1:1, and the residence time of the wastewater is 30 minutes; then it enters the micro-electrolysis / Fenton zone for treatment, adding acid to adjust t...

Embodiment 3

[0080] Landfill leachate, stock solution COD 3930mg / L, pH 6.2, B / C 0.26. Using an advanced oxidation coupling device and process treatment for refractory organic wastewater treatment of the present invention, the raw water enters the first ozone oxidation zone for treatment, the ozone input is 2g / h, and the wastewater residence time is 30min; then enters the multi-dimensional electrocatalysis / The micro-electrolysis area is treated, and the anode plate is coated with IrO 2 titanium plate, the cathode plate adopts a graphite plate with a purity of 99.9%, the distance between the anode plate and the cathode plate is 5cm, and the current density is controlled at 7mA / cm 2 , electrocatalytic particles and micro-electrolysis particles are mixed at a ratio of 1.5:1, and the residence time of wastewater is 80 minutes; then enter the micro-electrolysis / Fenton zone for treatment, add acid to adjust the pH value to 3.0, and control the current density at 7mA / cm 2 , the wastewater reside...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com