Composite reverse-phase demulsifying agent for treating oil refinery sewage and preparation method of composite reverse-phase demulsifying agent

A reverse-phase demulsifier, oil refinery technology, applied in the direction of separation method, grease/oily substance/suspended matter removal device, liquid separation, etc., can solve the problem of high consumption of reverse-phase demulsifier, high oil removal rate and long processing time etc. to achieve good deoiling effect, good surface activity and strong demulsification ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

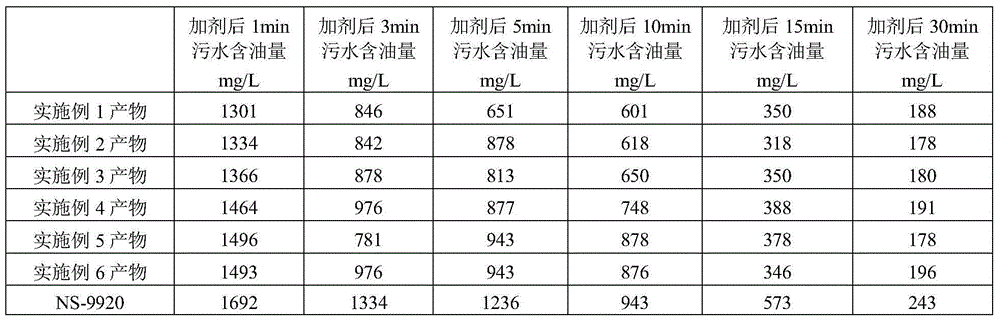

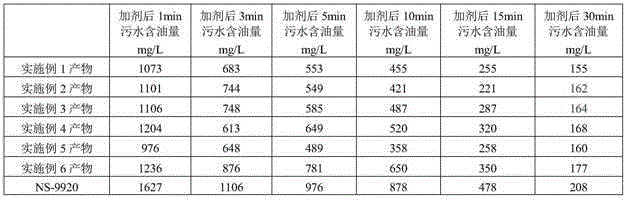

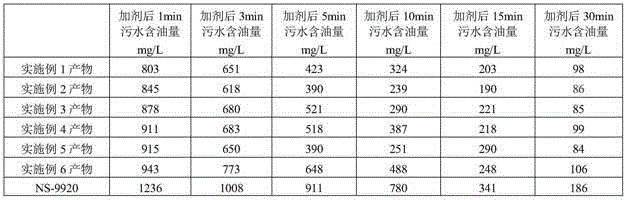

[0015] First take by weighing 0.1% polyaluminum ferric silicate, 0.1% polydimethyldiallylammonium chloride and 1% cationic polyacrylamide, which account for the mass fraction of inverse demulsifier, and mix the polyacrylamide in a stirred tank. Dissolve ferric aluminum silicate in water, keep low-speed spiral stirring (60-200 rpm), then continue to add polydimethyldiallyl ammonium chloride until completely dissolved, finally slowly add cationic polyacrylamide, stir until A completely homogeneous aqueous solution, that is, a composite inverse demulsifier for the treatment of refinery sewage.

[0016] The obtained inverse demulsifier is applied to the oily sewage of the delayed coking unit according to SY / T 0530-2011 oilfield produced water oil content determination method-spectrophotometry. When the dosage is 30ppm, the oil removal rate in water is 94.3%. When the dosage is 100ppm, the removal rate of oil in water is 95.2%, and when the dosage is 300ppm, the removal ratio of oi...

Embodiment 2

[0018] First, take by weighing 1% polyaluminum ferric silicate, 0.1% polydimethyldiallyl ammonium chloride and 1% cationic polyacrylamide, which account for the mass fraction of the inverse demulsifier. Dissolve ferric aluminum silicate in water, keep low-speed spiral stirring (60-200 rpm), then continue to add polydimethyldiallyl ammonium chloride until completely dissolved, finally slowly add cationic polyacrylamide, stir until A completely homogeneous aqueous solution, that is, a composite inverse demulsifier for the treatment of refinery sewage.

[0019] The obtained inverse demulsifier is applied to the oily sewage of the delayed coking unit according to SY / T 0530-2011 oilfield produced water oil content determination method-spectrophotometry. When the dosage is 30ppm, the oil removal rate in water is 94.5%. When the dosage is 100ppm, the removal rate of oil in water is 95.0%, and when the dosage is 300ppm, the removal ratio of oil in water is 97.4%.

Embodiment 3

[0021] Firstly, take respectively 0.1% polyaluminum iron silicate, 0.5% polydimethyldiallyl ammonium chloride and 1% cationic polyacrylamide, which account for the mass fraction of the inverse demulsifier, and mix the polyacrylamide in a stirred tank. Dissolve ferric aluminum silicate in water, keep low-speed spiral stirring (60-200 rpm), then continue to add polydimethyldiallyl ammonium chloride until completely dissolved, finally slowly add cationic polyacrylamide, stir until A completely homogeneous aqueous solution, that is, a composite inverse demulsifier for the treatment of refinery sewage.

[0022] The obtained inverse demulsifier is applied to the oily sewage of the delayed coking unit according to SY / T 0530-2011 oilfield produced water oil content determination method-spectrophotometry. When the dosage is 30ppm, the oil removal rate in water is 94.5%. When the dosage is 100ppm, the removal rate of oil in water is 95.0%, and when the dosage is 300ppm, the removal rati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com