Remediation of fipronil and/or ethiprole contaminated sediments by using biochar and detection method thereof

A biochar and sediment technology, applied in the field of environmental remediation, can solve the problem of measuring the free dissolved concentration of fipronil and ethiprole, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

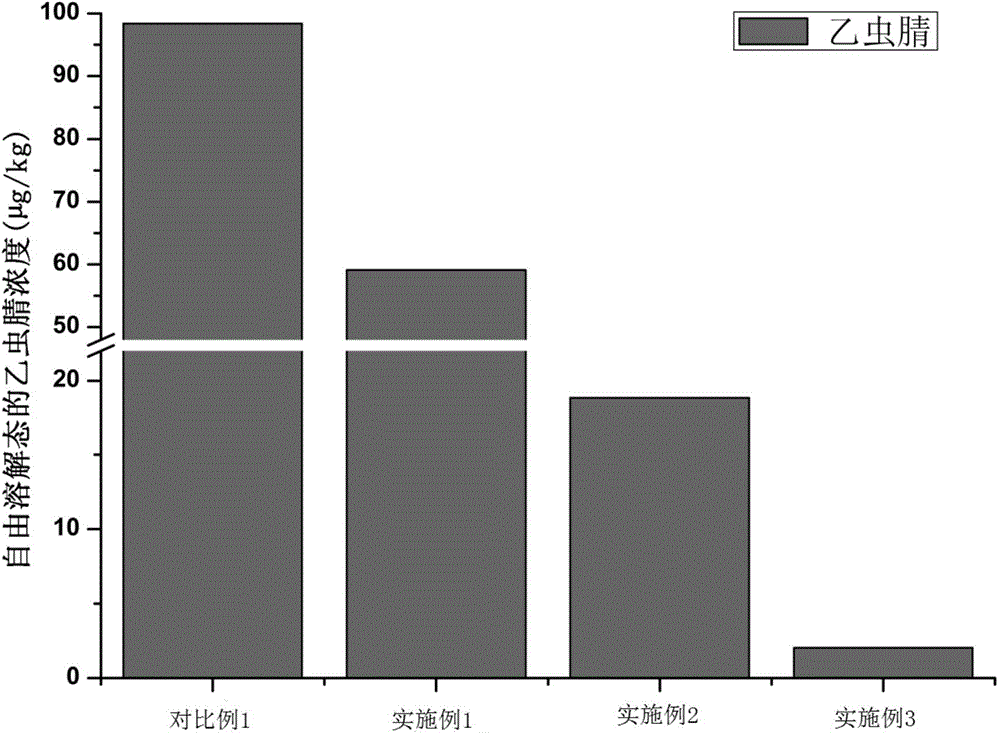

Embodiment 1

[0069] (1) Cut the magnolia wood into sections, put it in a closed container, put it into the muffle furnace, turn on the switch, raise the temperature to 700°C under anoxic conditions, keep it for 4 hours, take it out after cooling to room temperature, and crush it to the particle size Less than or equal to 2mm, ready for use.

[0070] (2) Add the biochar prepared by step (1) into fipronil and / or ethiprole polluted sediments, the quality of adding biochar is 1% of the sediment mass; stir and place it at 10 rpm Minutes on a shaker in the dark at room temperature for 30 days.

[0071] (3) Take 4 g of the sediment and add it to 40 mL of water, then add 0.2 g of polyoxymethylene resin; sterilize with 0.2% sodium azide solution; put the whole system into a shaker and vibrate at a constant speed of 150-200 r / min for 27 After ~30 days, take out and clean and dry the polyoxymethylene resin; put the polyoxymethylene resin in 40mL of methanol, analyze it at a speed of 150~200r / min for...

Embodiment 2

[0083] (1) Cut the magnolia wood into sections, put it in a closed container, put it into the muffle furnace, turn on the switch, raise the temperature to 700°C under anoxic conditions, keep it for 4 hours, take it out after cooling to room temperature, and crush it to the particle size Less than or equal to 4mm, ready for use.

[0084] (2) Add the biochar prepared by step (1) into fipronil and / or ethiprole polluted sediments, the quality of adding biochar is 5% of the sediment quality; stir and place at 10 rpm Minutes on a shaker in the dark at room temperature for 30 days.

[0085] (3) Take 4 g of the sediment and add it to 40 mL of water, then add 0.2 g of polyoxymethylene resin; sterilize with 0.2% sodium azide solution; put the whole system into a shaker and vibrate at a constant speed of 150-200 r / min for 27 After ~30 days, take out and clean and dry the polyoxymethylene resin; put the polyoxymethylene resin in 40mL of methanol, analyze it at a speed of 150~200r / min for...

Embodiment 3

[0091] (1) Cut the magnolia wood into sections, put it in a closed container, put it into the muffle furnace, turn on the switch, raise the temperature to 700°C under anoxic conditions, keep it for 4 hours, take it out after cooling to room temperature, and crush it to the particle size Less than or equal to 4mm, ready for use.

[0092] (2) Add the biochar prepared by step (1) into fipronil and / or ethiprole polluted sediments, the quality of adding biochar is 10% of the sediment quality; stir and place it at 10 rpm Minutes on a shaker in the dark at room temperature for 30 days.

[0093] (3) Take 4 g of the sediment and add it to 40 mL of water, then add 0.2 g of polyoxymethylene resin; sterilize with 0.2% sodium azide solution; put the whole system into a shaker and vibrate at a constant speed of 150-200 r / min for 27 After ~30 days, take out and clean and dry the polyoxymethylene resin; put the polyoxymethylene resin in 40mL of methanol, analyze it at a speed of 150~200r / min...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com