Lacosamidesolid preparation and preparation method thereof

A solid preparation, lacosamide technology, applied in the field of medicine, can solve the problems of low dissolution rate of preparations, many granulated fine powders, poor fluidity and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] Embodiment 1 (1000 pieces amount)

[0024] Lacosamide 100g

[0025] Microcrystalline Cellulose PH102 24g

[0026] Croscarmellose Sodium 24g

[0027] Hypromellose 2.4g

[0028] Crospovidone CL 24g

[0029] Optimized Microcrystalline Cellulose 60g

[0030] Colloidal silicon dioxide 2.4g

[0031] Magnesium Stearate 2.4g

[0032] Gastric soluble film coating premix 7.2g

[0033] making process:

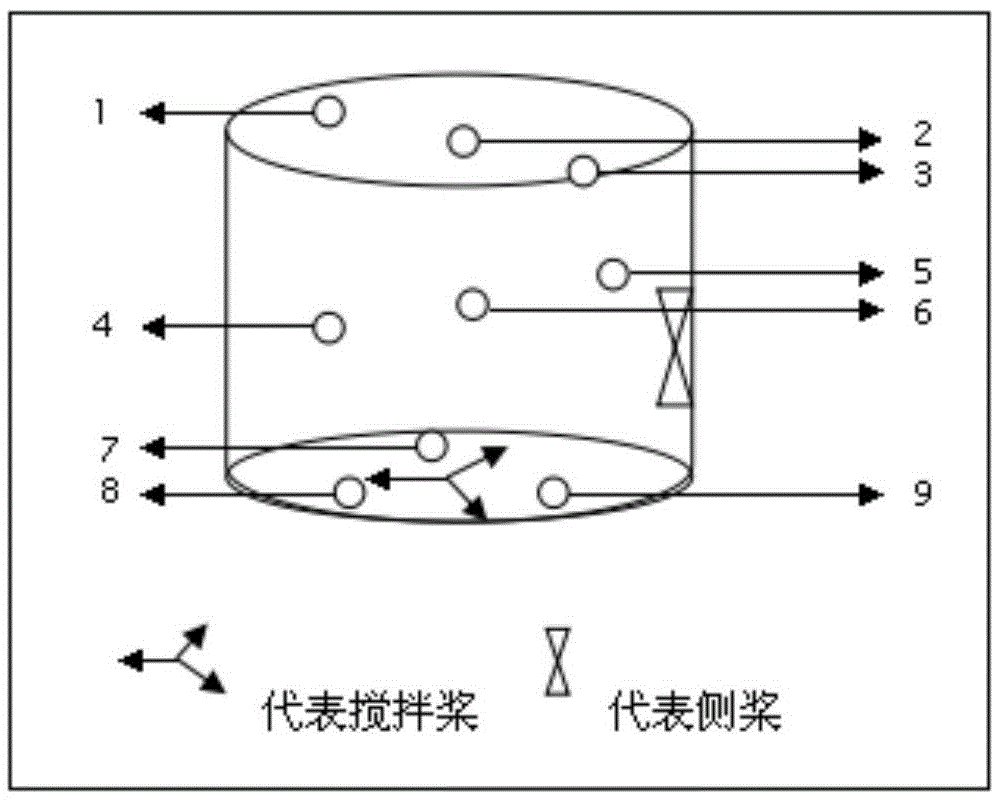

[0034] (1) Put the prescribed amount of lacosamide, microcrystalline cellulose PH102, and croscarmellose sodium in a wet mixer, and take three samples from the upper, middle, and lower parts of the mixer in 15 minutes, and measure the content , to calculate the content uniformity. Granulate and dry to obtain Mixture 1.

[0035] (2) Add optimized microcrystalline cellulose, crospovidone CL, colloidal silicon dioxide and magnesium stearate to mixture 1, and mix them together.

[0036] (3) Compression, coating and packaging.

Embodiment 2

[0037] Embodiment 2 (quantity of 1000 pieces)

[0038] Lacosamide 100g

[0039] Microcrystalline Cellulose PH102 36g

[0040] Croscarmellose Sodium 12g

[0041] Hypromellose 2.4g

[0042] Crospovidone CL 12g

[0043] Optimized Microcrystalline Cellulose 72g

[0044] Colloidal silicon dioxide 2.4g

[0045] Magnesium Stearate 2.4g

[0046] Gastric soluble film coating premix 7.2g

[0047] making process:

[0048] (1) Put the prescribed amount of lacosamide, microcrystalline cellulose PH102, and croscarmellose sodium in a wet mixer, and take three samples from the upper, middle, and lower parts of the mixer in 15 minutes, and measure the content , to calculate the content uniformity. Granulate and dry to obtain Mixture 1.

[0049] (2) Add optimized microcrystalline cellulose, crospovidone CL, colloidal silicon dioxide and magnesium stearate to mixture 1, and mix them together.

[0050] (3) Compression, coating and packaging.

Embodiment 3

[0051] Embodiment 3 (quantity of 1000 pieces)

[0052] Lacosamide 100g

[0053] Microcrystalline Cellulose PH102 30g

[0054] Croscarmellose Sodium 18g

[0055] Hypromellose 2.4g

[0056] Crospovidone CL 18g

[0057] Optimized Microcrystalline Cellulose 66g

[0058] Colloidal silicon dioxide 2.4g

[0059] Magnesium Stearate 2.4g

[0060] Gastric soluble film coating premix 7.2g

[0061] making process:

[0062] (1) Put the prescribed amount of lacosamide, microcrystalline cellulose PH102, and croscarmellose sodium in a wet mixer, and take three samples from the upper, middle, and lower parts of the mixer in 15 minutes, and measure the content , to calculate the content uniformity. Granulate and dry to obtain Mixture 1.

[0063] (2) Add optimized microcrystalline cellulose, crospovidone CL, colloidal silicon dioxide and magnesium stearate to mixture 1, and mix them together.

[0064] (3) Compression, coating and packaging.

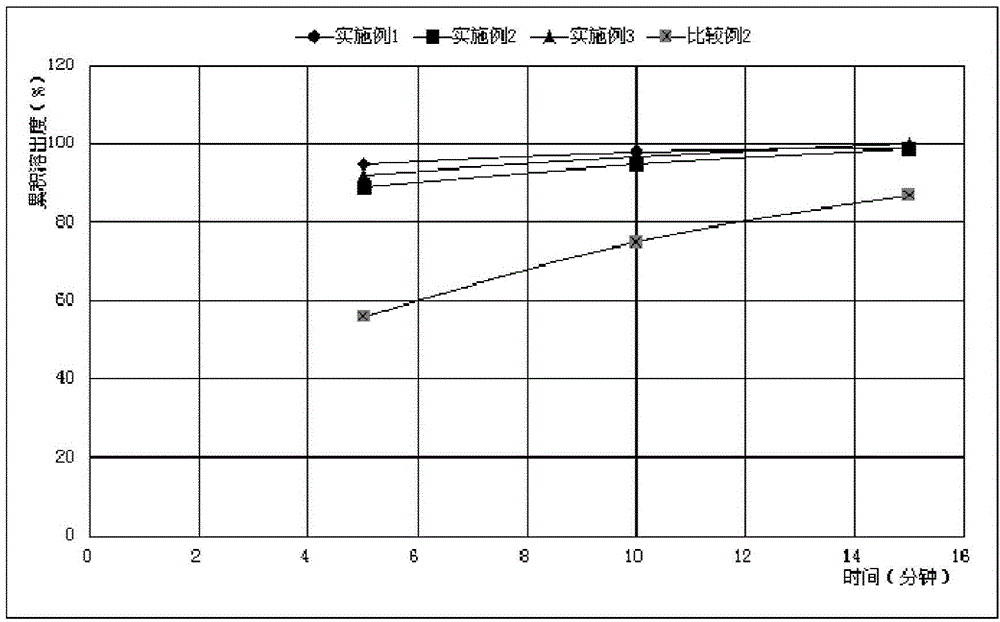

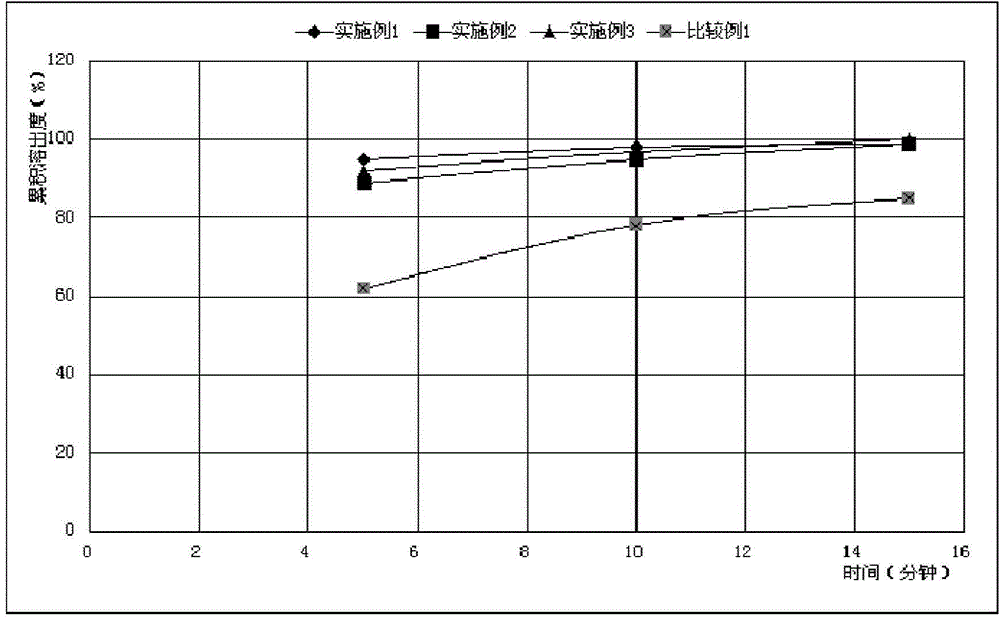

[0065] For the convenience of comparison ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com