A frequency conversion air conditioner

An inverter air conditioner and air conditioner technology, which is applied in the field of inverter air conditioners, can solve the problems of small flow changes, flow adaptability that cannot meet the flow requirements of inverter air conditioners, and unsatisfactory seasonal energy efficiency ratio SEER, etc., so as to reduce power consumption, The effect of improving the seasonal energy efficiency ratio and good cooling effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

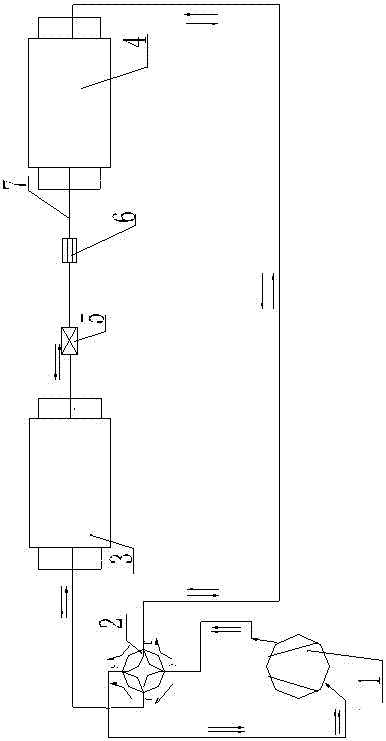

Embodiment 1

[0026] Such as figure 1 As shown, it is an air conditioner equipped with a flow conversion device, including a compressor 1 with pipeline circulation, a four-way valve 2, a condenser 3, and an evaporator 4. The pipeline is equipped with a refrigeration variable flow element, which can adjust the distribution of the total refrigerant flow. In this embodiment, the electronic expansion valve 5 is preferred. A line 7 of a nozzle 6 . The first nozzle 6 is composed of a copper tube and a riser set in the copper tube. A small hole is arranged in the center of the riser along the axial direction. The two ends of the small hole are trumpet-shaped diameter-expanding structures. 4 The inlet end of the cooling direction, the distance between the first nozzle 6 and the inlet end of the evaporator 4 in the cooling direction is 1cm, the first nozzle 6 is composed of a copper tube and a riser installed in the copper tube, and the center of the riser is provided with a small hole in the axial...

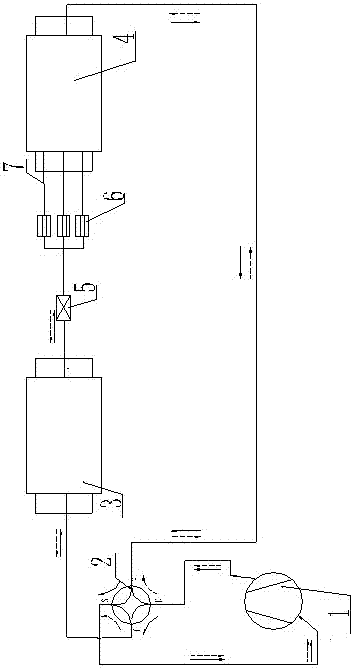

Embodiment 2

[0030] The rest is the same as that of Embodiment 1, except that the effective throttling length of the small hole in the riser of the first nozzle 6 is 10 mm.

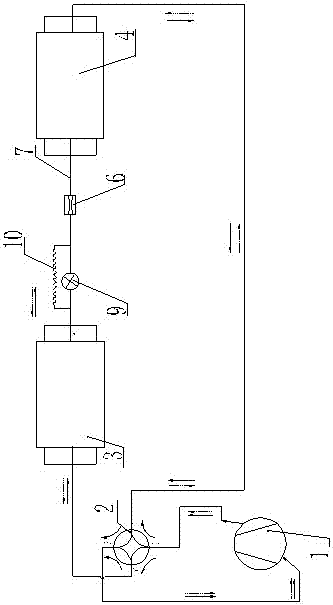

Embodiment 3

[0032] The rest is the same as that of Embodiment 1, except that the effective throttling length of the small hole in the riser of the first nozzle 6 is 7 mm.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com